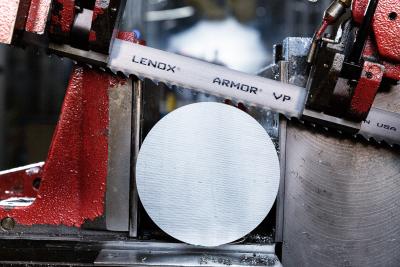

LENOX continues to advance its range of industrial products with the introduction of the new Armor VP bandsaw blade. The Armor VP is ideal for the customer who is looking for high cutting rates and long blade life across a wide range of materials.

The Armor VP bandsaw blade was designed for customers who need to cut faster in order to meet their demands. Key industries and customers include steel service centers and metal manufacturers within the aerospace, oil and gas and defense industries. Armor blades by LENOX were first introduced to the market in 2005, and the company has continued to make innovative enhancements to the product line over the years. The Armor VP bandsaw blade is the latest enhancement that will allow LENOX to re-establish a firm hold in product performance leadership.

The Armor VP band saw blade boasts extreme cutting rates in a wide range of materials. A few of the important benefits of the blade include:

Faster cutting increases productivity: State-of-the-Art Coating Technology enables an enhanced AlTiN (Aluminum, Titanium and Nitrogen) ARMOR coating to protect the blade’s teeth from heat, allowing for faster cutting rates and increased productivity.

Consistently long blade life: An advanced grade of carbide that is honed with HONEX Technology limits tooth wear, enabling long blade life consistently, blade after blade.

Quick cuts on a wide range of metals: Armor VP can handle a wide range of materials at high cutting rates, allowing users to limit blade changes and increase their productivity.

“The Armor VP bandsaw blade has performed extremely well with our customers, allowing them to increase their productivity,” commented Dan Fernandes, senior product manager.“ At LENOX, we are committed to understanding the needs of our customers and designing innovative tools that help them to be more efficient in their everyday tasks.”

Contact Details

Related Glossary Terms

- bandsaw

bandsaw

Machine that utilizes an endless band, normally with serrated teeth, for cutoff or contour sawing. See saw, sawing machine.

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- bandsaw blade ( band)2

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).