Aeroel MecLab.X Laser Micrometer

Aeroel MecLab.X Laser Micrometer

Marposs has announced the availability of its Aeroel MecLab.X laser micrometer systems, providing ultrahigh accuracy diameter measurements for components such as electric motor shafts, gage or piston pins, hydraulic components or any number of ground or turned parts. The benchtop Meclab.X systems require no PC, making them highly suitable for the workshop environment and for most common applications.

Marposs has announced the availability of its Aeroel MecLab.X laser micrometer systems, providing ultrahigh accuracy diameter measurements for components such as electric motor shafts, gage or piston pins, hydraulic components or any number of ground or turned parts. The benchtop Meclab.X systems require no PC, making them highly suitable for the workshop environment and for most common applications. They deliver extremely high accuracy at a reasonable price point.

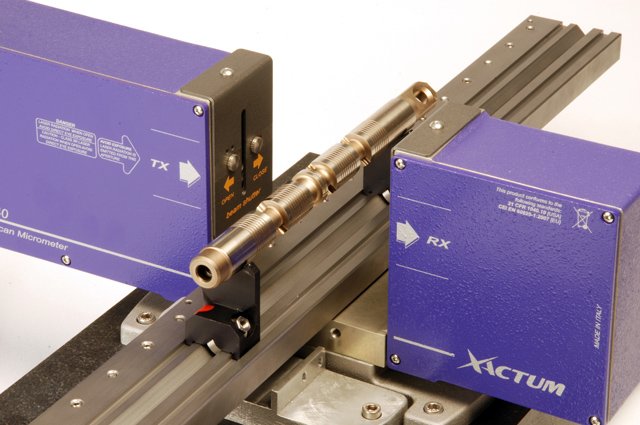

The Meclab.X systems are designed to be used as an off-line bench-top gauge with the flexibility to check a wide range of components with different shapes and sizes without resetting or remastering. They measure the part diameter D and the position of the part axis C or the position of the edges of the part all referred to the center of the measuring field and checks tolerance by comparing actual dimensions to the programmed limits. Unique to Aeroel technology is the fact that there is no measuring drift due to changing room temperatures.

The Meclab.X systems use a CE-200 operator interface panel with integrated touch sensitive keyboard and large LCD screen to provide an extremely friendly user-interface. There are three measuring modes – Free Running, On-Comm and Single Shot and On-Command Continuous. All results are stored in the memory and can be downloaded to a remote computer. The ease of use makes the system easy to learn regardless of operator skill or experience.

Available in two basic styles, the Meclab.X40 has a measuring field of up to 40mm and can measure diameters from 0.06 to 38 mm with a single shot repeatability (±2σ) ± 1.5 μm and with an excellent repeatability (T=1s, ±2σ) of ± 0.07 μm.

The Meclab.X80 has a measuring field of up 80mm and can measure diameters from 0.75 to 78 mm with a single shot repeatability (±2σ) ± 3.5 μm and with an excellent repeatability (T=1s, ±2σ) of ± 0.2 μm. The accuracy of these two basic styles in all the measuring field is for the Meclab .X40 ± 0.5 μm and for the Meclab .X80 ± 2 μm.

Also available is Meclab.X-S featuring a flat granite basement with a precision linear stage to mount holding accessories and to move the part. The Meclab.X-SR version additionally includes a base mounted under the granite base, which contains the electric supply and control circuits for optional accessories.