United Grinding Asia Pacific (UGAP) Pte. Ltd. is the new group subsidiary of United Grinding Group (UGG). UGG has had a presence in Southeast Asia for many years thanks to representatives and the Walter EWAG Asia Pacific subsidiary.

The company said that the new group strengthens United Grinding’s presence in the region with grinding, eroding, laser, and measuring machines.

"Strategically, Southeast Asia is a vital region for us. Establishing a United Grinding subsidiary was a logical step to further our activities in the region," said Stephan Nell, CEO of the United Grinding Group.

The potential is high, and the number of customers is continuously increasing. "Proximity to our customers has always been important to us to ensure fast and effective support," added Nell. “The ability to offer our bundled technology and application know-how from a single subsidiary will bring many advantages to customers.”

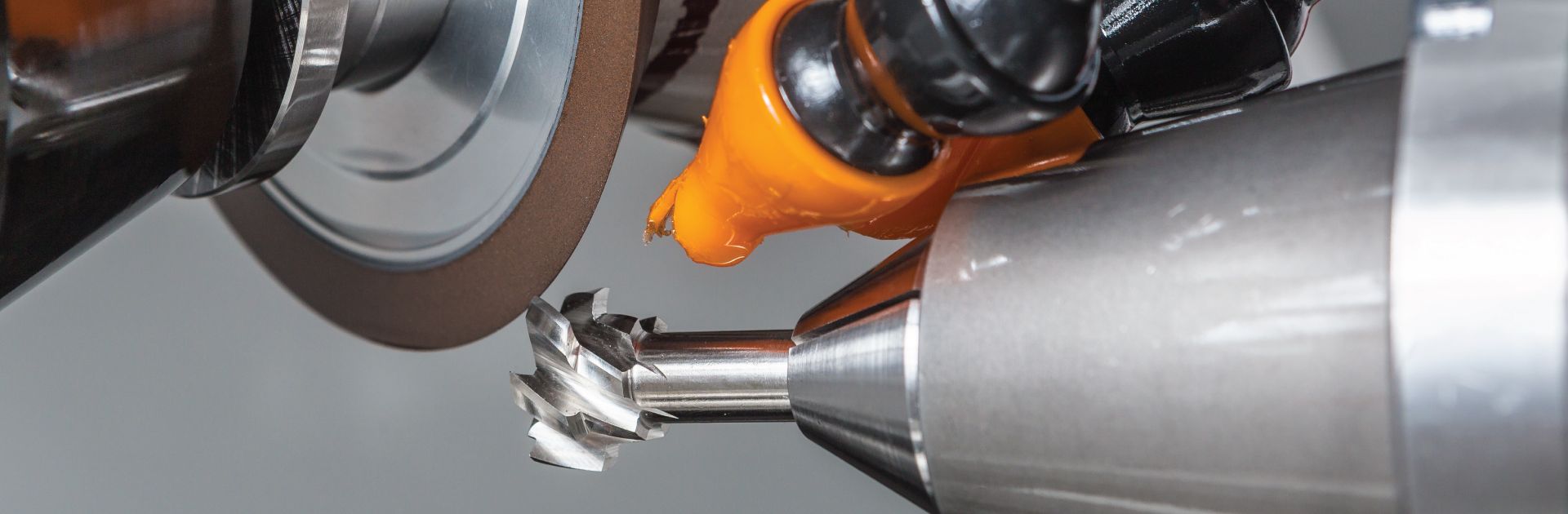

Michael Schmid, CEO of the new United Grinding branch and already responsible for the Southeast Asian business of the Walter and EWAG brands for more than 20 years, said: "It’s exciting news. We can bundle the strength of our powerful team in the joint group subsidiary and serve our customers even better. In the future, we will offer all three group technologies (surface and profile grinding, cylindrical grinding, and tool grinding) under one roof. I am convinced that bundling and intensifying our activities in this region is a win-win for all parties involved."

Contact Details

Contact Details

Related Glossary Terms

- cylindrical grinding

cylindrical grinding

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.