Dear Doc: Are there any hard-and-fast rules for selecting downfeed rates in Blanchard grinding?

The Doc replies: Here’s one rule — downfeed fast enough to keep your wheel sharp, but not so fast that you gobble up your wheel.

Yes, I realize that’s still pretty general, without any specific downfeed rate in inches per minute. But in Blanchard grinding, there are just too many factors to give a specific value. But let’s elaborate, using the machine spindle power as a guide.

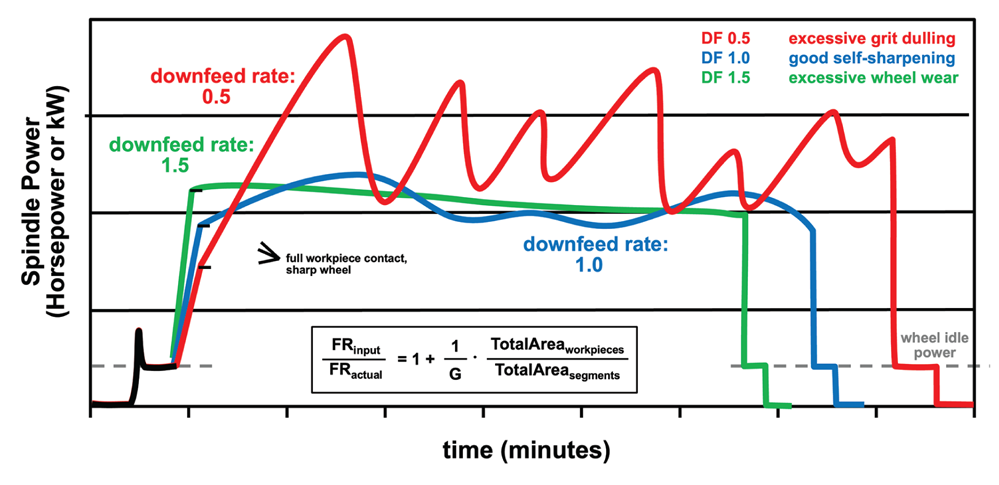

Many Blanchards will have some sort of power meter (or amp meter) mounted somewhere. (If not, a well-tuned ear can serve as a quasi power meter.) The figure shows three different feed rate examples: 0.5, 1.0 and 1.5 times some downfeed variables in inches per minute.

If we downfeed too timidly, power will start off low. But the grits in the wheel (or segments) will dull — and power will increase rapidly (red curve). We’ll then suffer a series of “wheel collapses” as the grits dull, shed off and then dull again. If we downfeed reasonably aggressively (blue), power will start off higher (as we are downfeeding faster), but the wheel will self-sharpen. Power will still increase, and we’ll experience some small collapses. But they won’t be dramatic. This is the sweet spot for the operation. Finally, if we downfeed too fast (green), we’ll just eat through our wheel. Granted, power won’t increase. But that’s because the grits are being lost before they have a chance to dull. Moreover, actual material-removal rates will be low (because we’re gobbling up our wheel).

What if our wheel is harder (as in H-grade instead of G-grade)? Then we must feed faster, in order to put larger forces on the grits to get them to break out. Harder-graded wheels are fabulous if you push them hard – and disastrous if you’re timid. A terrible mistake with a medium-or hard-grade wheel is to say: “Uh oh. Power is increasing. I think I’ll slow down my downfeed rate.”

That’s why a lot of operators just go with a soft-grade wheel (say, F-grade): They’re just easier to use, and you don’t have to worry about grit dulling. But you end up consuming a helluva lot of wheel in the process (which leads to longer cycle times).

Some other facts to consider:

- Grit Aggressiveness (“grit penetration depth” or “chip thickness”) depends on wheel rpm. Higher rpm equals a less-aggressive grind, which equals less wheel self-sharpening.

- Grit Aggressiveness depends on downfeed rate. Faster downfeed rate equals more aggressive grind.

- Grit Aggressiveness depends on the workpiece distance from center of the magnetic chuck. Further away from the center equals a more-aggressive grind.

- The number of workpieces on the magnet does not affect aggressiveness. Yes, it certainly affects machine power, wheel consumption and material removal rate. But each little grit on the wheel/segment will penetrate the same depth (and experience the same self-sharpening) whether there are a lot of workpieces or just a few. If you stack your magnet full but use a slow downfeed rate, your grits are more prone to dulling.

- Magnet/chuck rpm doesn’t affect things much. This may seem counterintuitive. But both theory and practice show that changing workpiece rpm has less effect than you might think (or even no effect).

Finally, if you’re good at math, take a look at the equation in the figure. It’s the ratio of input depth (or feedrate, if you prefer) to the achieved depth (or feedrate). Ideally, this ratio would be close to 1.0, which means there’s very little wheel wear. In a terrible situation, it would be 100, which means we’d have to tell the machine to feed down 0.100" to remove 0.001" of material. Now, what value to use for G-ratio? That’s difficult. For a difficult-to-grind high-speed steel, this might only be G=1.0. For unhardened steel, you should be able to achieve something like G=5 to G=30. If you’re grinding soft steel and getting G=1.0? Then your wheel is too soft or you’re downfeeding too fast.

Those are general guidelines that work – until they don’t work! Blanchard grinding is a monstrosity. Theory works, except when it doesn’t. But these general guidelines should help guide you to achieve higher removal rates.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- magnetic chuck

magnetic chuck

Workholding device used on surface grinders and milling machines for holding ferrous parts with large, flat sides. Holding power may be provided by permanent magnets or by an electromagnetic system. See chuck.