Industry News

11/17/2020

TCI Precision Metals launched a program to provide customers with first article sample parts on request with accompanying production volume quotation.

11/16/2020

Charlie Ingram, executive vice president and chief marketing officer of Eriez Manufacturing, plans to retire at the end of the year.

11/13/2020

Since the onslaught of the coronavirus pandemic, manufacturers have dealt with supply chain issues. In this Q&A, two industry leaders discuss the pandemic, the supply-chain and bringing manufacturing back to U.S. shores.

11/12/2020

Big Kaiser Precision Tooling has promoted Jack Burley to president and chief operating officer as of Jan. 1, 2021. Chris Kaiser, Big Kaiser president and CEO of 30 years, will take on the role of executive advisor.

11/11/2020

Mazak Corp. Canada opened a technical center in Edmonton, Alberta, Canada, with a grand opening and ribbon cutting event attended by Alberta Premier, Jason Kenney.

11/10/2020

Capital Machine and OMAX Waterjet Corp. host three days of one-on-one machinery demonstrations showcasing the OMAX 80X Series JetMachining Center.

11/09/2020

Eriez, an exhibitor at the PACK EXPO Connects Virtual Trade Show, is presenting four live demonstrations featuring the company’s Xtreme Metal Detectors and vibratory equipment.

11/06/2020

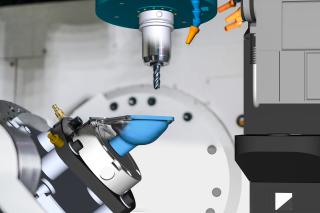

At Emuge-Franken, manufacturers of threading, gaging, clamping and milling technology, sensors and dynamometers from Kistler are used to aid in the development of new precision tools.

11/05/2020

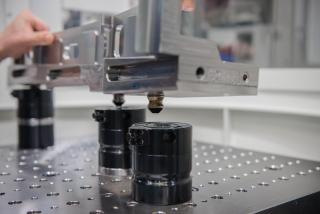

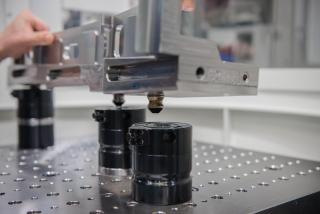

Grinding jobs requires strict tolerances. On grinding machines, the tolerances for the dimensions, form and position of finishing processes run tight, and in many cases, shops check these specifications against hard data. Studer machines can use cameras and laser systems to in-process measurements.

11/04/2020

Mastercam has launched the Mastercam Educators Alliance (MEA) to bring together the community of educators that teach and use Mastercam and provide a platform for sharing valuable information.

11/03/2020

Mitsui Seiki USA Inc. overhauled its U.S. Website to be more interactive with new features such as the Tech Exchange community section.

11/02/2020

Capital Machine Technologies Inc., a distributor of metal fabrication and robotic welding equipment, is hosting the OMAX Dallas Demo Days. Visitors can learn about the Maxiem 1530 JetMachining Center.

10/29/2020

The tool and mold industry is designing and specifying ever more complex geometries and freeform surfaces and the industry is placing ever greater demands on clamping technology to accomplished these needs. Zero-point clamping technology from Andreas Maier Fellbach (AMF).helps them meet these challenges.

10/28/2020

The ThyssenKrupp Crankshaft Co. in Danville, Illinois, operates up to 21 shifts per week to produce forged crankshafts for the North American heavy-duty automotive, truck, and engine markets. Meeting production needs requires precise technology, including a Zema Numerika GH1500 grinding machine from Junker.

10/26/2020

Takumi USA has partnered with Renishaw to be the first CNC machine tool brand to offer Renishaw’s Set and Inspect app for the Fanuc control.

10/23/2020

After 265 laps, car No. 96 crossed the finish line at the Hollywood Casino 400 race, finishing at 27, garnering 10 points in the NASCAR Cup Series, and capping off a successful first weekend with GF Machining Solutions as the car’s primary sponsor.

10/22/2020

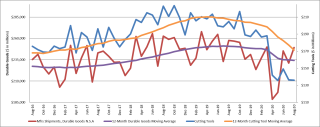

While the latest data on cutting tool orders shows a decline, orders appear to have “found a bottom” and tool suppliers look to the future with the release of a multitude of new tooling, workholding, machine tools and accessories into the marketplace.

10/21/2020

The fourth Industrial Revolution promises new efficiencies and productivity gains for manufacturers. Machine tool suppliers are integrating Industry 4.0 capabilities and software companies that are providing powerful new tools such as those that utilize artificial intelligence. CAM software from ESPIRIT from DP Technology offers features to drive production improvement.

10/20/2020

Whether operators use neat oils or water-miscible coolants in wet cutting machine tools or tool grinding machines, the coolants are subject to heavy contamination. VOMAT technology offers a variety of clean coolant technology to solve this problem and produce better cuts.

10/19/2020

Omni Aerospace needed to produce large, flight-ready parts within strict design tolerances and surface finishes in a time-sensitive manner. Starrag's Ecospeed F1540 machining centers fit the bill.