Industry News

10/21/2021

Tools today are far superior to those used in previous firearm production methods, which provides the opportunity to combine operations into a single cutting tool, eliminating the need for additional tooling in the machine shop.

10/19/2021

Machining titanium cost-effectively requires special attention to the distinctive features of this material – particularly for choosing the right tools.

09/24/2021

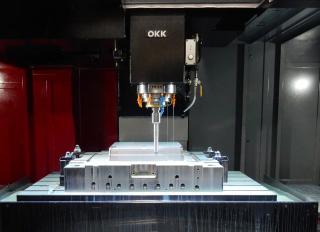

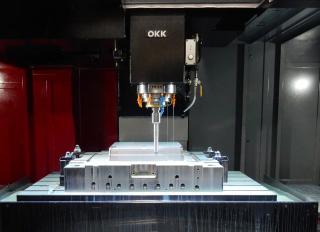

Keeping up with technology advances means keeping CNC equipment up-to-date, which allows injection molding companies to accept jobs that they might ordinarily have to decline.

09/12/2021

Repair center offers quicker turnaround times and proactive solutions to rebuild customers’ equipment.

09/01/2021

Stefan Steenstrup has been appointed president and CEO of Seco Tools as of Oct. 1, 2021, succeeding Fredrik Vejgården who decided to leave Seco to start his own business.

08/27/2021

Fast, flexible custom tooling, easy access to tool data through cloud technology and automation are some of the technologies driving tool production processes, according to a recent discussion between two industry executives.

08/15/2021

On Sept. 14-15, Mazak will host an open house at its new Florida Technical Center in Orlando.

07/27/2021

Mazak hopes to “move manufacturing forward” at its Oct. 25-29 Discover 2021 technology and education event.

07/11/2021

The 53,000 sq. ft. center was built specifically for industrial machine tool training and supports flexible machine layouts and configurations.

06/21/2021

At the 2021 Precision Machining Technology Show (PMTS) scheduled for Aug. 10 to 12 in Cleveland, Mazak will highlight some of its latest high-output, cost-effective and space-saving machine tool technology.

05/14/2021

After surviving a tornado, TDC Engineering rebuilds with a new equipment supplier, Kent USA.

05/10/2021

The ultimate accuracy and reliability of a machine tool depends in no small degree on the alignment checking during its assembly. Seeking an alternative to traditional error measurement techniques, Hurco Manufacturing Ltd. (Hurco) chose Renishaw’s XK10 alignment laser system to increase both precision and throughput of its machine tools..

05/07/2021

The Schaller Group, a Michigan-based metal forming company, invested in CNC technology to drive growth in the family-owned company and support the company principle's passion for hydroplane racing.

05/04/2021

Unlike machining other materials, machining stainless steel requires review of myriad aspects prior to beginning work in the machine shop. While machining stainless has unique challenges, its benefits outweigh those challenges.

03/02/2021

Greenleaf Corp. in Saegertown, Pennsylvania, released the XSYTIN-360, a new line of high-performance solid ceramic end mills, to the global market.

02/05/2021

Starrag is a manufacturer high-precision machine tools for milling, turning, boring and grinding workpieces for a variety of industries. Its rigid and robust equipment can also be used for making farming equipment.

12/16/2020

A tool and process monitoring system from Marposs is part of a project that was named a 2020 Henry Ford Technology Award (HFTA) winning program.

12/13/2020

Wear pads between the saddle and the machining bed on lathes and CNC machines are being replaced with a wear-resistant polymer known as Vesconite Hilube