Music was in the air at the press conference Fritz Studer AG held at its headquarters in Steffisburg, Switzerland, Feb. 9. With a theme of “The Sound of Studer,” the Music Motion Meeting 2024 event began with presentations by the cylindrical grinding machine builder’s board of directors: Jens Bleher, CEO; Sandro Bottazzo, chief sales officer; Daniel Huber, chief technology officer; and Stephan Stoll, chief operating officer. More than 60 journalists from about 20 countries attended the conference, including two from the U.S.

For 2023, the company’s 111th anniversary, Bleher said Studer had a successful fiscal year under difficult market conditions for capital equipment investments while achieving a new sales record in the customer care segment. With strong sales in December, he noted that the company is optimistic about the upcoming fiscal year. “We have turned our announcements into reality and used the time to improve our market position and strengthen ourselves for the future in the long term.”

While sales were weaker in some individual markets, such as Germany and China, and overall sales declined from 2022, Bottazzo said sales increased in other parts of the globe, such as Spain. “We achieved good results in many countries and even posted a new record order intake in some.”

Measured by customer segments, he noted, the aerospace industry once again generated the largest increase in new orders, overtaking the declining automotive and supplier segments. In addition, the tool grinding segment remained below expectations.

With grinder integration capability in digital ecosystems and portals to provide added value from data, Huber said “the entire orchestra has changed!”

Huber said C.O.R.E. (Customer Oriented REvolution), an operating system that equips a machine with intelligence, was a particular focus for new feature development in 2023. “Only those with intelligent machines will be successful.”

Stoll pointed out that even though sales were down last year, Studer’s production mix shifted to more complex and more expensive grinders. Also, the company will phase in new products during the third and fourth quarters.

After the presentations, the company announced the winner of the 2023 Fritz Studer Award. The trophy and prize money of 10,000 Swiss francs, about $11,430, went to Dr. Emil Sauter from the Institute for Manufacturing Technology and Machine Tools at ETH Zurich for his topic “Detection and avoidance of thermal damage for high-performance metal grinding processes using hybrid machine learning models.” The objective is to overcome current limits of grinding technology using artificial intelligence.

The event also included a guided company tour with sessions covering entry level grinding machines and automation, with the former including Michael Jackson-inspired dancing, plus a manic wolf character, and pulsing techno grooves providing the soundtrack for the latter.

The entry-level machines presented were the “pop star” favoritCNC universal cylindrical grinding machine and the S100 CNC internal cylindrical grinder. According to Studer, the favoritCNC is a leader in value for the money and can perform external and internal grinding in one setup. The S100 is suitable for a wide range of internal, face and external grinding applications of workpieces up to 550 mm (21.65"), including the clamping device, and up to 420 mm (16.5") in diameter.

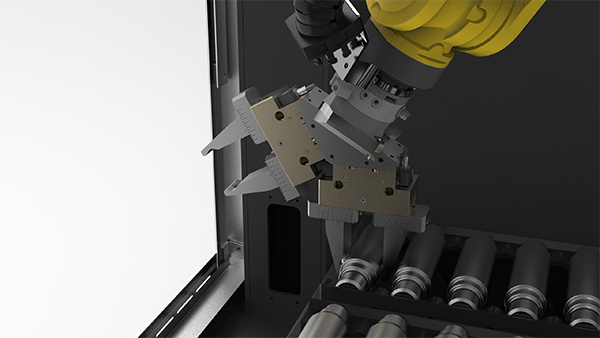

The insertLoad universal loading system was featured in “The Sound of Automation” session. Introduced at last year’s EMO trade show, insertLoad is initially only available for the S33 and S31 CNC universal cylindrical grinding machines, but the company is preparing other models for it. The S33 and S31 are suitable for small to large workpieces in single-batch, small-batch and volume production. The roboLoad loader system for the S121 Radius, S131 Radius and S141 Radius grinders was also displayed.

Music Motion Meeting 2024 concluded with a group dinner at the Kornhauskeller restaurant in Bern, with the energetic sound of the Take This band providing the entertainment.

Contact Details

Related Glossary Terms

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cylindrical grinding

cylindrical grinding

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.