Mention the name Connor Toor to most knife aficionados and you’ll receive a knowing nod. That’s because the founder and CEO of Toor Knives Inc. has developed a product line of which any entrepreneur would be envious, and he did so in less than a decade. Add to that, in 2018 the U.S. Marine Corps sent the rifle squad leader to Afghanistan for a year-long deployment just as his fledgling business was beginning to take off.

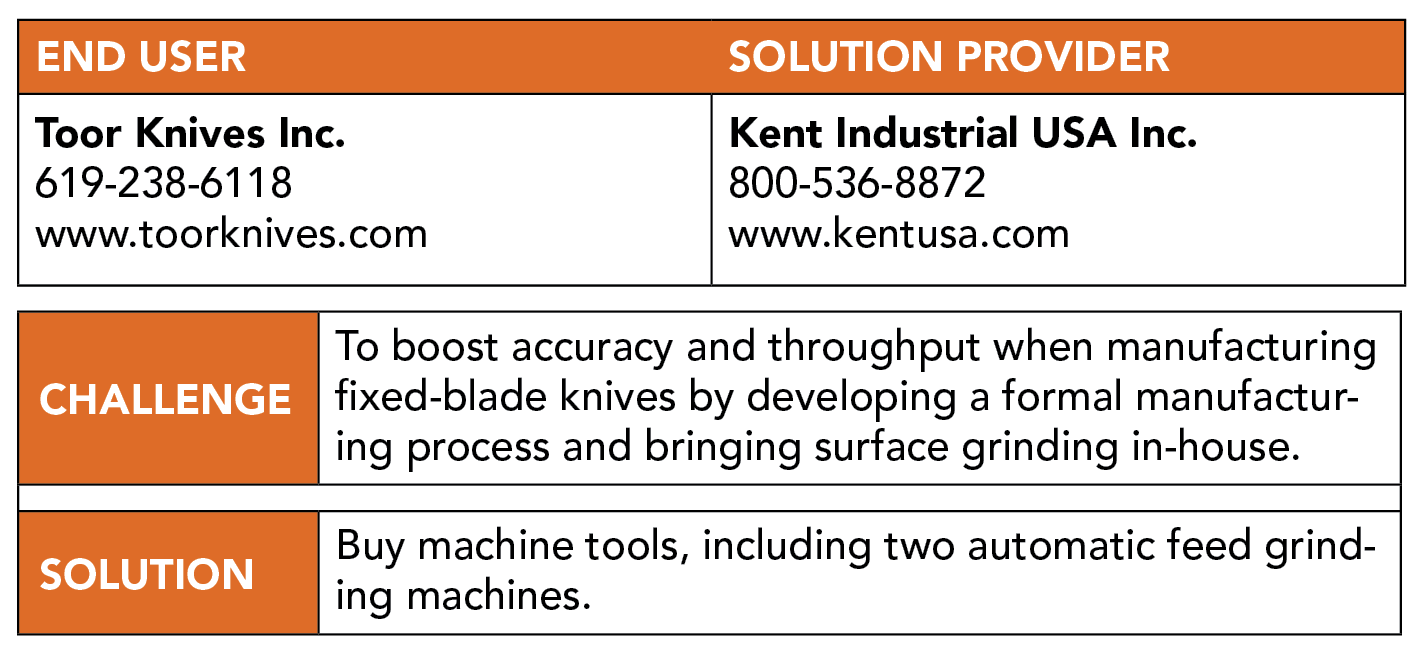

Once he was back home in El Cajon, California, Toor picked up where he had left off — developing and manufacturing a leading line of tactical, sportsman and every-carry knives that Toor estimates has a 1.5% to 2% global market share of fixed-blade knives.

“It was probably back in 2013 or so that I built a forge in my backyard and started tinkering around making fireplace hooks and random cool stuff, so I decided to try my hand at knife making,” Toor said. “I watched some YouTube videos, made a few trips to Home Depot for some mild steel and got pounding. I scrapped a lot of metal along the way, but it finally started coming together.”

Toor admits that he knew little about manufacturing when he first fired up his forge.

He’s since attended the machine technology course at San Diego City College, where he learned how to write G code and what machine to use for which process, adding to his bachelor’s degree in accounting and business management from California State University San Marcos.

Toor initially only made knives for friends. But those friends told their friends, and it wasn’t long before Toor began posting photos on the craft marketplace Etsy. He built a website, started earning a little money and, over the next year or two, realized he might be on to something much more than a hobby.

“So, I moved out of the backyard and into a U-Haul storage unit,” Toor said. “I had two 110-volt outlets and was chronically short on power, swapping out the drill press for the grinder, the grinder for the bandsaw, and so on. But it worked. I was making knives.”

He decided to take his venture more seriously. He brought in a friend and traded the storage unit for “some real commercial space,” Toor said. “We knew then that we’d have to develop a formal manufacturing process and figure out how to make these things at a larger scale.”

Part of that process involved machine tool and equipment purchases, which included grinders. Toor noted that his company started with belt grinders that had surface grinding attachments and were manually fed. To overcome issues with accuracy, Toor Knives outsourced grinding, with blades being ground on double-disc, Blanchard and large feed surface grinders.

When the time was right to bring grinding back in-house in 2019, Toor said he purchased a used SGS-1640AHD automatic feed surface grinder built by Tustin, California-based Kent Industrial USA Inc., which the company uses to make the blade blanks flat after heat treatment. The hardened steel workpieces have a hardness of about 60 HRC.

After becoming familiar with the Kent USA brand, Toor Knives purchased a new Kent SGS-2040AHD automatic feed surface grinder in early 2023. “We knew the controls, so we just stuck with it,” he explained.

“We run both of them 10 to 12 hours a day, so we probably grind a couple of thousand blanks a week,” Toor said, noting that the 50-person company runs two shifts in its approximate 2,787-sq.-m (30,000 sq. ft.) facility. “It’s a fairly basic process, but it’s an important step that we rely on for our downstream operations. We’re very happy with them, as well as the level of support we’ve received from Kent USA.”

Surface grinding, which is the sixth or seventh process in a 20-step procedure, removes 0.763 mm (0.030") of material from multiple blades in about four hours within a tolerance of ±0.051 mm (±0.002"), Toor explained. After a worker sets up the grinders, an operator monitors them as they run unattended, and the company’s equipment list also includes a double-disc grinder. “One person can run multiple grinders instead of having to kind of babysit each individual machine. That’s important for us.”

The Toor Knives brand has 20 retail SKU numbers and is looking to add more, with the company producing batches of roughly 500 of each product monthly. Toor Knives also makes larger quantities for partner companies, which are sold under a private label.

“We aim for 12 inventory turns per year and remain committed to making everything here in El Cajon,” Toor said. “One of the things that set us apart as a company has been our ability to design and implement new, creative textures across all of our handle patterns. That’s something a lot of our competitors overlook.”

As manufacturers are aware, finding skilled labor continues to be a battle. So, to attract top-notch people and remain competitive, Toor Knives consistently sells its products at a higher price than what is typically expected for a knife.

“Part of that premium is due to our shift in focus from being a product-first company to a people-first company, which began during the COVID-19 pandemic,” he said. “By prioritizing our employees, they have in turn supported our processes, resulting in improved products. Yes, it also required reorganizing our initiatives and priorities, adopting a fresh perspective, and working closely with our staff, but I feel we are on the right path.”

Contact Details

Related Glossary Terms

- bandsaw

bandsaw

Machine that utilizes an endless band, normally with serrated teeth, for cutoff or contour sawing. See saw, sawing machine.

- drilling machine ( drill press)

drilling machine ( drill press)

Machine designed to rotate end-cutting tools. Can also be used for reaming, tapping, countersinking, counterboring, spotfacing and boring.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- surface grinding

surface grinding

Machining of a flat, angled or contoured surface by passing a workpiece beneath a grinding wheel in a plane parallel to the grinding wheel spindle. See grinding.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.