Alpha Sheet Metal Works is expanding its operations in Charleston County, South Carolina. The company’s $3.7 million investment will create 14 new jobs.

With more than 80 years of experience, Alpha Sheet Metal Works specializes in steel, stainless steel and aluminum metal products. The company’s products range from individual parts to complete automated assemblies.

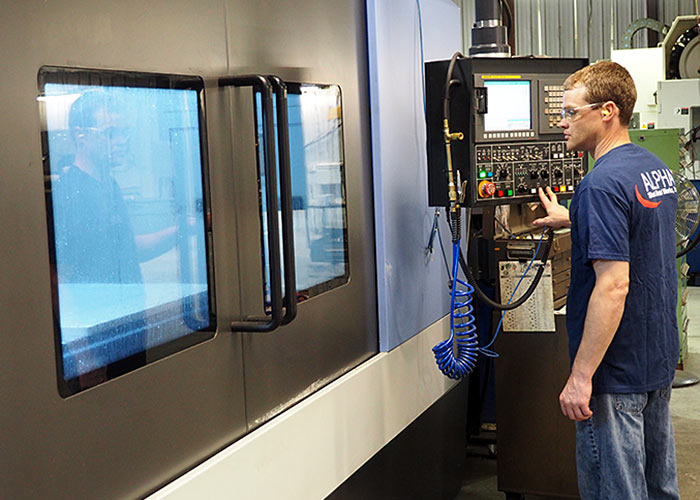

Alpha Sheet Metal Works will add 24,000 square feet next to its existing facility and increase its CNC machining, assembly and large-format fabrication capabilities.

"As a family-owned business, we’re thrilled to expand our operations in Charleston County, said Alpha Sheet Metal Works President Joseph W. Schady. "This community has been incredibly supportive, and we’re excited to continue serving the local businesses and industries here. Our expertise in steel, stainless steel and aluminum fabrication, combined with our commitment to quality and customer satisfaction, makes us well-suited to meet the region’s diverse needs.”

In addition to its laser and waterjet cutting, forming, welding and QC equipment, the company currently operates a Doosan CNC Milling DNM 750L, a Doosan CNC Milling DMV 3016 L, a Doosan CNC Milling MV 4020, and a Doosan CNC LatheLynx 220L, as well as several manual milling machines and manual lathes.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- waterjet cutting

waterjet cutting

Fine, high-pressure (up to 50,000 psi or greater), high-velocity jet of water directed by a small nozzle to cut material. Velocity of the stream can exceed twice the speed of sound. Nozzle opening ranges from between 0.004" to 0.016" (0.l0mm to 0.41mm), producing a very narrow kerf. See AWJ, abrasive waterjet.