Insert features serrated cutting-edge geometry for efficient rough milling

Insert features serrated cutting-edge geometry for efficient rough milling

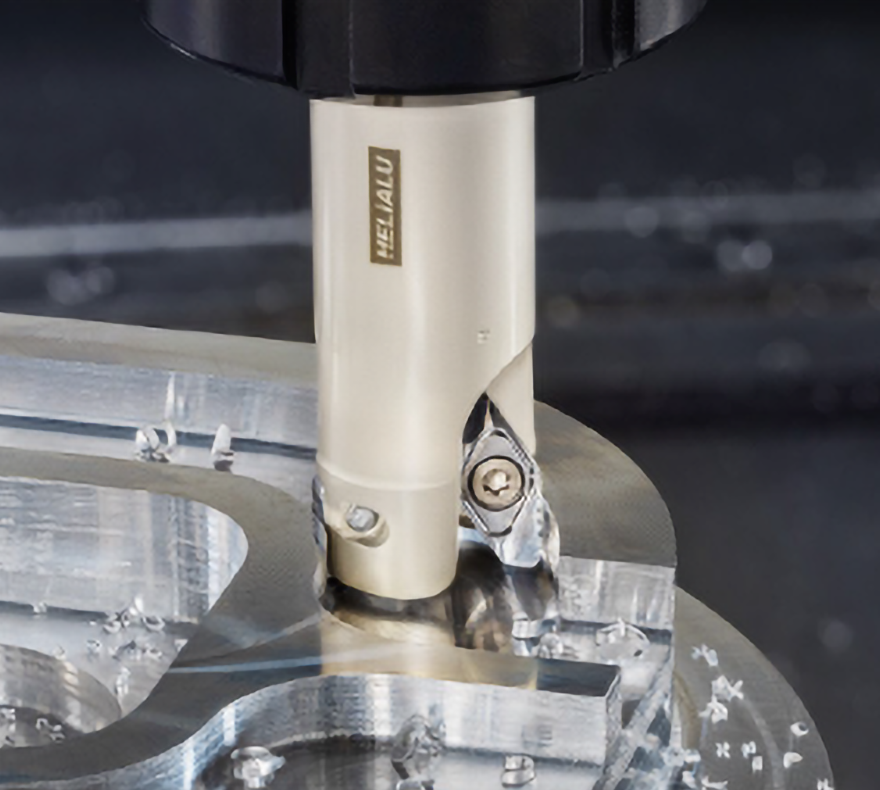

Iscar's HELI-ALU LINE of tooling includes a new insert with serrated edges. The new insert, designated as HSM90S APCR 140520R-FWP28, features a radius of 2.0mm (.0787"). It has a super positive and sharp serrated cutting edge geometry, along with a polished rake surface, which ensures efficient milling for aluminum alloys and other non-ferrous materials. (ISO N grade of application)

Iscar's HELI-ALU LINE of tooling includes a new insert with serrated edges. The new insert, designated as HSM90S APCR 140520R-FWP28, features a radius of 2.0mm (.0787"). It has a super positive and sharp serrated cutting edge geometry, along with a polished rake surface, which ensures efficient milling for aluminum alloys and other non-ferrous materials. (ISO N grade of application)

The cutting-edge geometry of the insert splits the chips into small pieces and generates low cutting forces, enabling increased feed rates for higher machining productivity.

Serrated cutting edge advantages

- Wide chips are divided into small segments. This greatly contributes to effective chip evacuation and diminish negative re-cutting.

- Reducing cutting forces and decreasing heat generation lessen the mechanical and thermal loads on a tool, enabling prolonged tool life which can be translated into higher productivity by increasing cutting parameters.

- Improving the tool's dynamic behavior ensures stable cutting in unfavorable conditions (high tool overhang, thin-wall workpieces, poor workholding etc.).

Insert features

- Wide sharp-edged wiper for improved surface finish.

- Ground insert periphery for improved precision.

- Polished rake and relief surfaces to improve chip flow and eliminate built-up edge (BUE).

- Dividing a wide chip into smaller segments significantly improves chip evacuation, enhancing tool performance even when using high-speed machining (HSM) methods.