Industry News

11/20/2024

Students in Itawamba Community College’s Precision Machining Technology program have a new toolbox, courtesy of a $20,000 grant by the Gene Haas Foundation.

11/19/2024

Flex Machine Tools, an American manufacturer and provider of machine tool solutions worldwide for metal fabrication operations, will host an Open House Event at Flex headquarters in Wapakoneta, Ohio, on Thursday, Dec. 5, 2024, from 9:00 a.m. through 4:00 p.m.

11/18/2024

Olympic Steel Inc., a national metals service center, has acquired Metal Works. The all-cash purchase is expected to be immediately accretive. Terms were not disclosed.

11/15/2024

Dormer Pramet has unveiled a redefined brand identity that the company said marks the beginning of a new era for the company.

11/14/2024

Metal Supermarkets, a supplier of small-quantity metals, named the six winners of its 10th annual Metal My Way contest.

11/13/2024

In a strategic move, Star Cutter has assumed design and manufacturing rights to Tru Tech grinding technology, extending the company’s solutions across the grinding lifecycle into blank preparation and cylindrical grinding

11/13/2024

Swiss tooling company REGO-FIX welcomed attendees and manufacturing partners from across the globe for a day-long grand opening celebration of the company’s Center for Machining Excellence (CME). The event took place Oct. 24 at the company’s North American headquarters in Whitestown, Indiana.

11/13/2024

Sandvik Coromant, a global leader in metal-cutting tools and solutions, recently announced the appointment of Thomas Henry as the new vice president of marketing for the Americas, effective Nov. 4, 2024.

11/11/2024

The tool’s shape is a dead giveaway. The tooling, which resembles a Christmas tree, is often used for finishing blade root grooves and blade roots of turbines, is alternatively known as a fir-tree design, or a pine-tree, or now, a Pagode Tree Cutter developed by cutting tool solutions provider EMUGE-FRANKEN.

11/11/2024

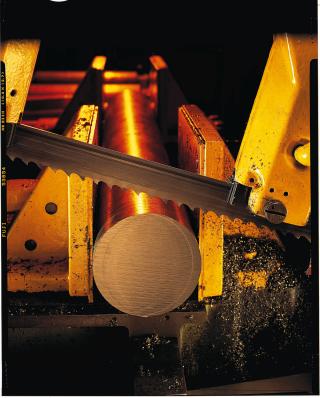

Burton Mill Solutions has acquired Oregon Industrial. Burton will be able to supply metal cutting bands that meet factory specifications for tough metals and abrasive surfaces.

11/08/2024

Since May 2024, Intercable Tools GmbH, a more than 50-year-old manufacturer of connection technology and tools, has been using ultrasonic deburring technology from the German company UltraTEC innovation GmbH, part of the VOLLMER Group, to remove burrs from hydraulic units automatically and in a contact-free manner.

11/07/2024

The nLIGHT Inc. company has announced the global launch of two new products: nfinity and ProcessGUARD, designed to meet advanced metal fabrication demands.

11/06/2024

UNITED GRINDING Group has signed an agreement with Georg Fischer AG (GF) to acquire its GF Machining Solutions Division (GFMS) with the aim of strengthening its position in the market

11/01/2024

Kennametal Inc. has named David Bersaglini vice president of Kennametal Inc. and president of the Metal Cutting segment.

10/31/2024

Global standards organization ASTM International has been selected to launch a center of excellence focused on supporting standardization of critical and emerging technologies (CETs).

10/30/2024

Wintriss Controls Group has added flexible and affordable purchase options for ShopFloorConnect® OEE, Production Tracking, and Data Collection software, which allows users to quickly and easily leverage data from their machines.

10/29/2024

Ceratizit USA has named Eric Gerringer as the company’s new technical director. Gerringer brings over 25 years of leadership development and applications experience to the role with his expertise in strategic leadership, business development and technical engineering.

10/28/2024

Emuge-Franken USA, a manufacturer of high-performance taps, thread mills, drills, end mills, clamping devices and other rotary tools, has appointed Mike Patterson as national sales manager for the U.S. and Canada.

10/25/2024

The Fair Friend Group (FFG) said it has initiated a comprehensive strategic realignment to address the "current global challenges in the machine tool industry and to strengthen its competitive position.

10/24/2024

ABB Robotics is sponsoring MassRobotics, a leading innovation hub and startup accelerator for robotics in the United States.