Industry News

03/17/2025

Ametek Inc. acquired in February Kern Microtechnik, a manufacturer of high-precision machining and optical inspection solutions.

03/14/2025

AMT – The Association For Manufacturing Technology, which represents U.S.-based providers of manufacturing technology, has elected its 2025-2026 board of directors. Michael Cicco, president and CEO of FANUC Corp., was elected to serve as chairman of the board for AMT.

03/13/2025

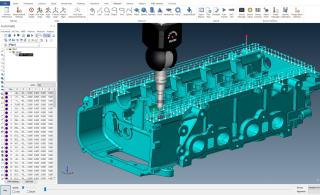

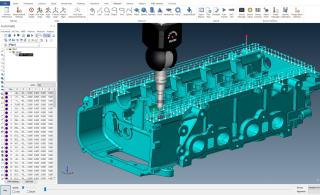

Sandvik has signed an agreement to acquire Verisurf Software Inc., a US-based 3D metrology software solutions provider.

03/12/2025

Ceratizit is realigning its international production network to "further strengthen its competitiveness in the global market for cemented carbide."

03/11/2025

REGO-FIX USA plans to celebrate the month of May and the Indianapolis 500 with its Center for Machining Excellence (CME) inaugural open house May 14 – 15 in Whitestown, Indiana.

03/10/2025

GROB Systems Inc., a developer of manufacturing systems and machine tools, plans to demonstrate power skiving capabilities as well as innovative fir tree mill finishing on its GROB G550T 5-axis mill-turn universal machining center.

03/07/2025

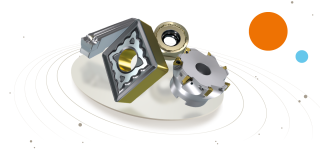

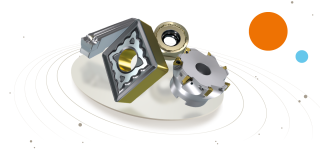

Dormer Pramet is expanding its portfolio of indexable tools with the launch of high-performance turning and milling solutions.

03/06/2025

The Movotrak CTU 7th axis robot features collision detection settings for programming and control benefits. Also, an industrial robot transfer unit (RTU) was launched, which can be integrated with a user’s preferred motor and drive.

03/05/2025

Heule will feature the DL2 – a small, robust, reliable mechanical deburring tool for 1.00mm to 2.1mm bores in a wide range of materials including steel, stainless steel, titanium, aluminum, and composites

03/04/2025

The L.S. Starrett Company will be featuring the automated inspection capabilities of its metrology and force measurement systems at Manufacturing Technology Series East (EASTEC).

03/04/2025

In the world of steel construction, surface preparation is more than a preliminary step—it’s a defining factor in durability and corrosion resistance. An autonomous solution that simplifies precision grinding and seamlessly integrates with automated shot blasting.

02/28/2025

Emuge-Franken USA, a manufacturer of high-performance taps, thread mills, drills, end mills, clamping devices, and other rotary tools, has introduced new MultiTAP NPT/NPTF Pipe Taps with a universal threading geometry for both job shops and production tapping.

02/27/2025

SW North America plans to conduct live demonstrations demonstration of SW North America’s BA 322i, a twin-spindle horizontal CNC machining center, making tibia spacers for knee prosthetics.

02/26/2025

Hypertherm Associates, a U.S.-based manufacturer of industrial cutting systems and software, will showcase its Powermax® plasma cutting technology at the CastExpo & Metalcasting Congress 2025, which takes place April 12-15 in Atlanta, Georgia. Visit Hypertherm at booth 1110 to see live demonstrations and examine parts cut with Powermax technology.

02/25/2025

Apple Inc. plans to spend more than $500 billion in the U.S. over the next four years, according to an Apple press release dated Feb. 24.

02/25/2025

A free FANUC training website offers engineer-led tutorials on robots and cobots to help anyone learn, troubleshoot and master automation.

02/24/2025

The L.S. Starrett Co., a manufacturer of precision measuring tools and gages, and metrology systems has appointed four new executives to its global organization, further strengthening its corporate management at the highest levels.

02/22/2025

Leeco Steel, the largest supplier of steel plate in North America, has promoted Ben Kincheloe to Director of Business Excellence, effective January 16, 2025. In his new role, Kincheloe will lead continuous improvement efforts in addition to managing safety and quality processes.

02/21/2025

EXAIR has introduced Catalog 36, a full-color, in-depth resource designed to help businesses tackle conveying, cooling, cleaning, blowoff, drying, coating, and static control challenges.

02/20/2025

Sunnen Products Company highlights its HTE-1600W Tube Hone, an all-electric precision honing machine designed for optimal bore geometry and surface finish in small-diameter, long-bore applications.