Eurotech Elite introduces new series of flat-bed lathes

Eurotech Elite introduces new series of flat-bed lathes

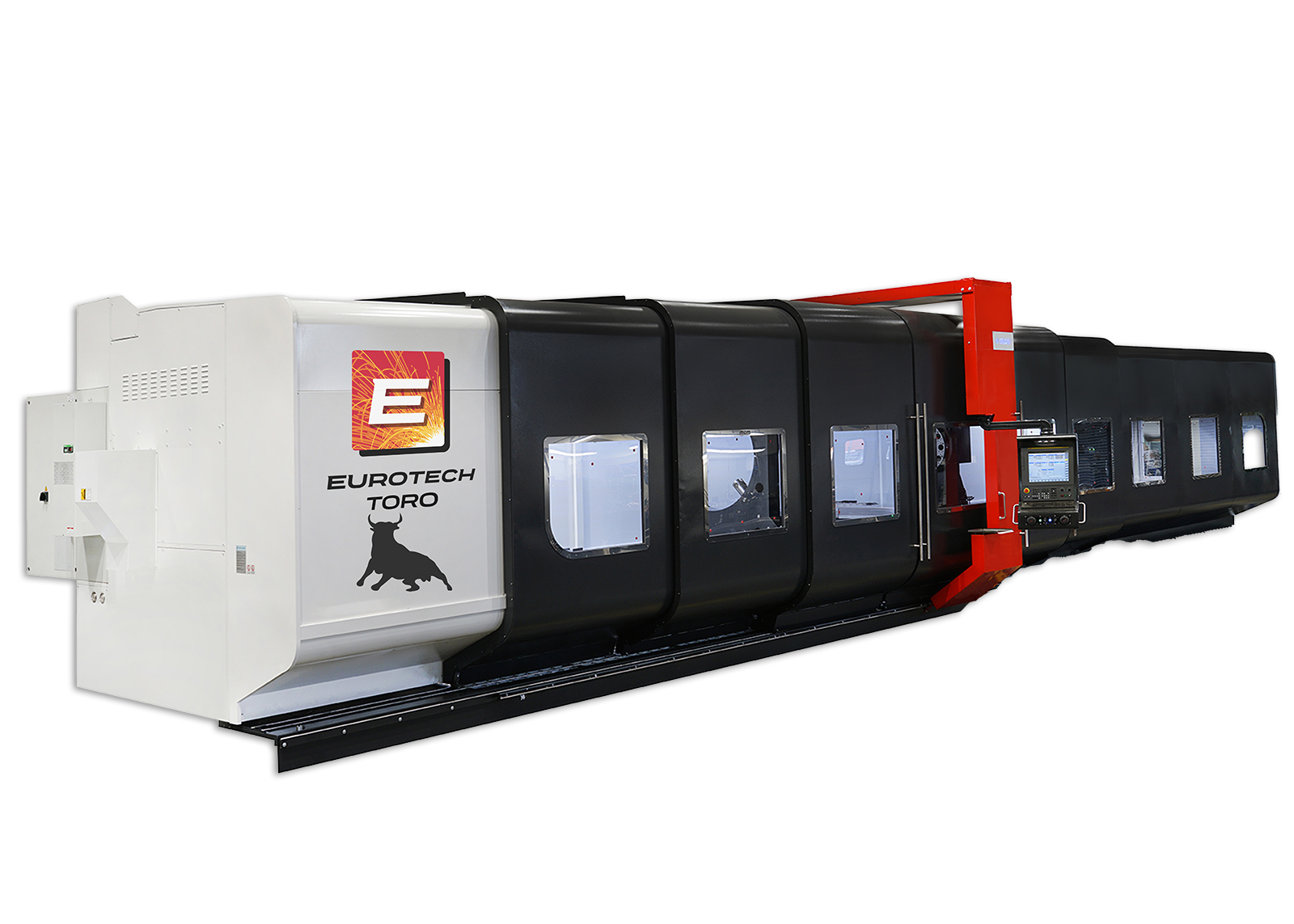

Eurotech Elite, a supplier of multi-axis, high-precision CNC machines, has expanded its product line with the launch of the Toro Series of horizontal flatbed lathes that are engineered with elite European craftsmanship and "tailored for North America's most demanding industries."

Eurotech Elite, a supplier of multi-axis, high-precision CNC machines, has expanded its product line with the launch of the Toro Series of horizontal flatbed lathes that are engineered with elite European craftsmanship and "tailored for North America's most demanding industries."

"The Toro Series is built for power and is the #1 trusted brand for the oil and gas and aerospace industry in Europe, so it was the perfect partnership for us—a combination of European precision and advanced technology with unmatchable options," said Jeff Walz, president of Eurotech.

Key highlights:

- Premium Threading Capabilities: Delivers superior threading performance not commonly available from competing flat bed lathes—ideal for oilfield and power industry components.

- Massive Capacity: Machines with up to 65 feet between centers and the ability to handle parts up to 90,000 pounds, making them the go-to solution for extreme part sizes and heavy-duty applications.

- Expanded Guideway Design:

Additional guideways provide greater stability and support for the workpiece

Enhanced vibration damping ensures higher accuracyhBetter load distribution extends machine life and cutting consistency - Precision and Rigidity: The structural integrity allows for tighter tolerances and smoother finishes even under the most aggressive cutting conditions.

- Versatility Across Industries: Built for oil & gas, power generation, rail, shipbuilding, aerospace, and other large-format machining sectors.

- Trusted European Build: Manufactured by our partner in Italy -- known across Europe for quality, innovation, and performance.

Click here to learn more about the new Toro Series from Eurotech.

? Visit: www.eurotechelite.com/products