Production managers in manufacturing often have to ask themselves: should we continue with conventional machining and coolant lubricants, or do dry machining or minimum quantity lubrication (MQL) represent viable alternatives? Several factors influence this decision. In Part 1 of this two-part series of technical articles being published in the run-up to EMO Hannover 2019, lubrication system experts and scientists give their assessment. Tool and machine manufacturers shed light on the subject in the second part.

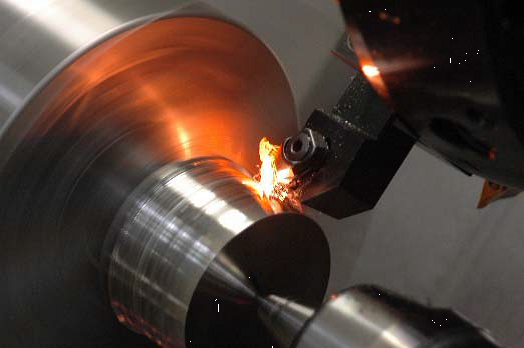

Very high temperatures are generated in the cutting zone during machining. Coolant lubricants reduce friction, provide cooling (but may also cause destructive thermal shocks) and support the removal of chips. Back at the turn of the millennium, some experts predicted dry machining would make a breakthrough as a substituting process. It is now time to assess the current position. In which areas have this process, or minimum quantity lubrication (as quasi-dry machining) become established, and to what extent? In this two-part technical report, lubrication system manufacturers, machine and tool suppliers and scientists provide a comprehensive assessment from various perspectives and identify the advantages and disadvantages of the respective technologies.

The shavings, which are produced when machining using minimum quantity lubrication, are virtually residue-free and can be recycled directly. Photo courtesy of bielomatik Leuze

Particular relevance for series machining

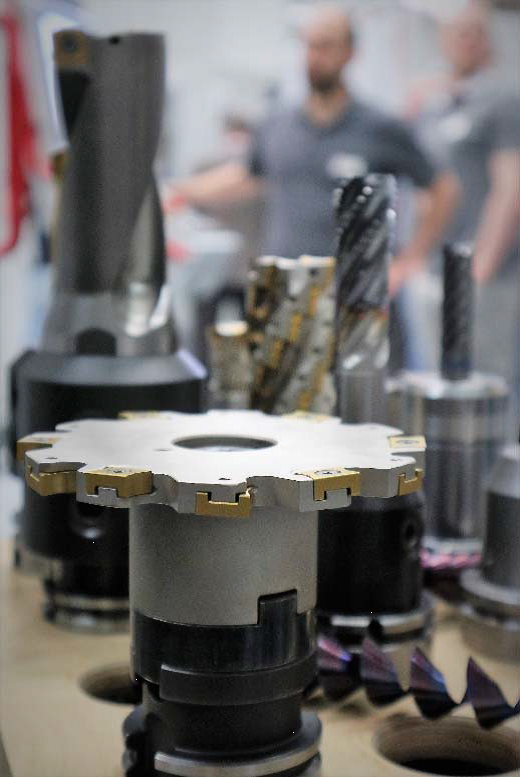

"The main area of application for minimum quantity lubrication lies in the machining of prototype parts as found in large-scale series production in the automotive industry, especially of powertrains. The parts range from the cylinder head and engine block to the crankshaft or camshaft, connecting rod, gearbox and wheel carrier," said Jürgen Keppler in technical sales at bielomatik Leuze GmbH + Co. KG, Neuffen, Germany. The Baden-Württemberg-based engineering company is a recognized specialist in the development and manufacture of high-quality MQL systems. "Further industrial applications include the machining of cubic components and mechanical engineering castings such as fittings, pump housings or valves. It is a great advantage in the aviation industry, too, if complex components are not flooded with emulsion."

The expert estimates that MQL is used for machining about 15% of new large-series components, rising to 70% for deep-hole drilling crankshafts, for example. "MQL will continue to grow in the other application areas I just mentioned," Keppler said. "The upswing in MQL machining predicted some 20 years ago has mainly occurred in the automotive sector. Here, the advantages of MQL could be fully exploited in the machining of cast and forged parts. The high quantities involved also allowed the related R&D work to be carried out. New application areas will also arise from the forthcoming changes in e-mobility and additive manufacturing. The great advantage of MQL lies in the cost savings to be made in resources such as oil, water and energy."

Further advantages are dry workpieces, no carry-over of emulsion and contamination in the production bays, and the prevention of associated health risks. "The constant further development of materials and applications is placing new demands on machining processes and thus on MQL systems. This will certainly result in interesting solutions," Keppler said.

There are many successful examples of dry machining in individual industries or companies. However, there are no widespread substitutes for the classic cooling lubricant concepts as yet. Photo courtesy of ISF

What do the scientists say?

"Thanks to modern cutting materials, dry machining has been introduced in almost all areas of machining production. Increasing cost pressure, but also energy consumption and ecological aspects are leading to a renaissance of these technologies," said Dr. Ivan Iovkov Head of Cutting Technology at the Institute of Machining Technology ISF of the Technical University of Dortmund. "Dry machining is not only used in conventional milling or turning. There are also efforts to minimise or completely avoid the use of coolant lubricants in complex processes, such as deep drilling and gear hobbing.

However, the cutting processes and the technology still need to be adapted in certain ways. Dry machining tends to be more common in big companies which process larger quantities than in smaller companies which specialize in varying types of high-precision and complex components.

"I think there will be both dry and wet machining in the future," he predicts. "We need to take a holistic view of production when deciding whether dry machining makes sense or whether it will involve disproportionately high process adaptation costs. The continuous further development of MQL device technology and coatings, the increasing accuracy of the machine park, but also digitalisation – for example through in-process sensor monitoring of relevant variables – will make it possible in the future to carry out more and more dry or MQL machining under robust practical conditions."

Users are recommended to take a holistic view when deciding whether to deploy dry or MQL machining or whether a classic process should be used. Photo courtesy of Dag Heidecker

It is too soon to speak of conventional machining processes being comprehensively replaced by dry machining or minimum quantity lubrication, as wet machining (involving larger quantities of coolant lubricant) still accounts for an estimated 85% of machining. Nevertheless, dry processes are conquering more and more areas, both in the general machining sector and above all in special areas.

In the second part of the article, tool and machine manufacturers take a practical view of the different production technologies and recommend adopting a holistic approach. Trade visitors to EMO Hannover 2019 will find extensive information and support which can help them find the right technology for their own individual applications.

Related Glossary Terms

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- emulsion

emulsion

Suspension of one liquid in another, such as oil in water.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.