DN Solutions successfully hosted DIMF 2025 (DN Solutions International Machine Tool Fair) from April 2 to 5 in Busan and Changwonc, in South Korea. At the event, the company unveiled its new DLX series of metal 3D printers, marking its official entry into the industrial Laser Powder Bed Fusion (LPBF) market.

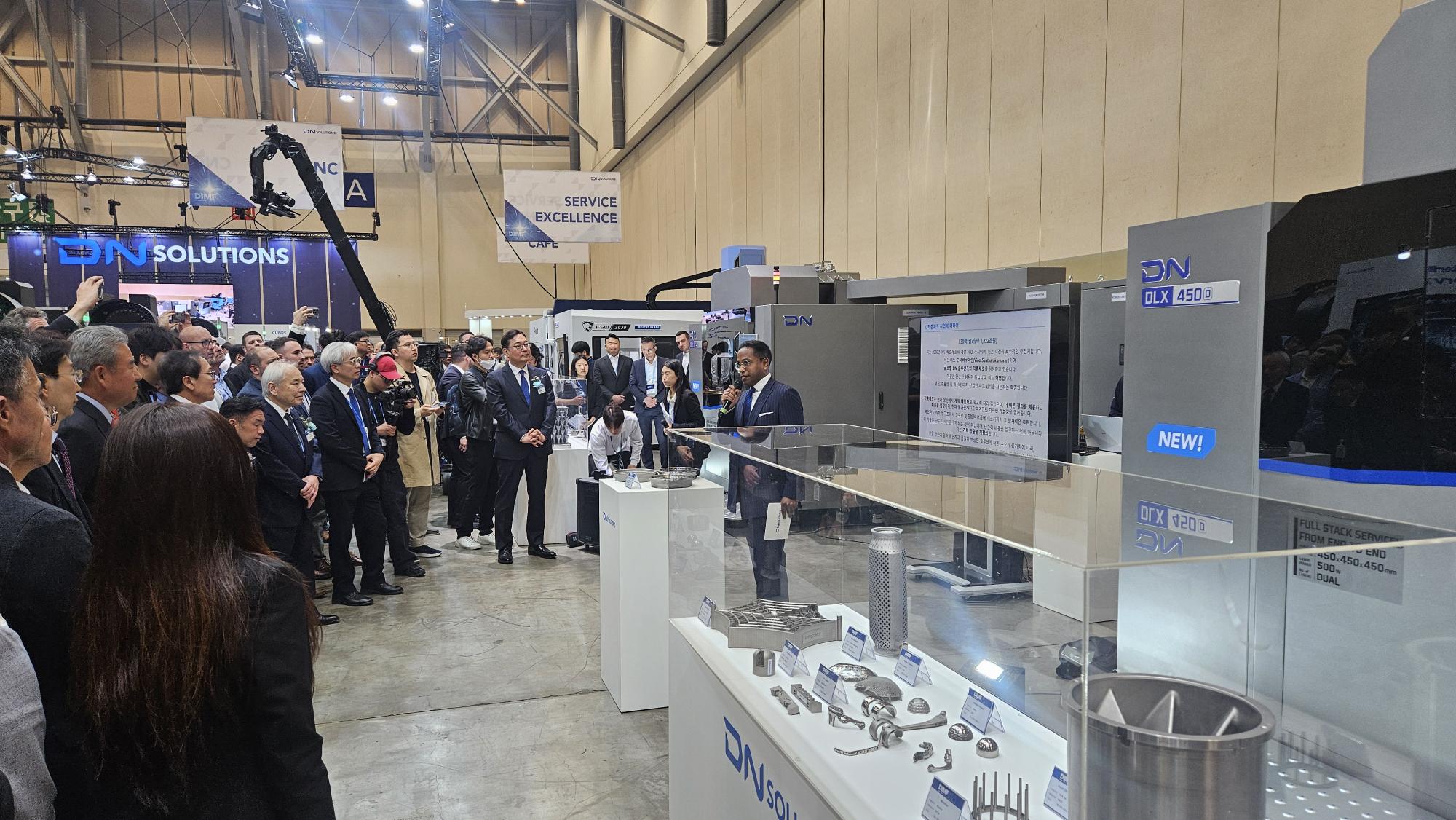

Themed “Automation Solutions Platform for All Machining Processes”, the 15th edition of this biennial open-house show attracted over 5,000 visitors, including 1,000 international partners and customers. The exhibition showcased more than 50 next-generation machines, automation systems, smart software, and—for the first time—metal additive manufacturing (AM) equipment.

High-precision metal AM systems

The highlight of DIMF 2025 was the DLX series, DN Solutions’ first industrial-grade LPBF metal 3D printers. The flagship DLX 450 was demonstrated live, building complex components up to 450 × 450 × 450 mm using materials such as aluminum alloys, Inconel, and titanium. The system supports single to quad fiber lasers (500W–1kW), with layer thicknesses of 30–90 μm and build speeds up to 20 cm³/hour.

The DLX series features DN Solutions’ proprietary AM software suite, supporting a full end-to-end workflow:

Identifying AM-ready parts - Estimating per-part production cost - Designing and optimizing support structures - Simulating and compensating for part deformation - Developing new material process maps - Improving quality with existing materials

This integrated approach ensures high precision, repeatability, and ease of adoption for manufacturers moving into metal AM.

Global rollout

To validate the technology, DN Solutions redesigned a spindle cylinder front cap for its multitasking machine using DfAM (Design for Additive Manufacturing). The result: a 20% performance gain from improved internal structure and simplified assembly.

DN Solutions also announced the opening of its Additive Manufacturing Solution Center (ASC) in Germany, with additional locations planned for South Korea and the United States. These centers will offer support for AM part design, process optimization, prototyping, and production.

“Additive manufacturing is no longer the future—it’s ready now,” said Wonjong Kim, CEO of DN Solutions. “By combining AM with our expertise in machining and automation, we’re building a complete manufacturing platform for the next generation.”

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.