When full-diameter steel slotting is the only option

When full-diameter steel slotting is the only option

ProvenCut recipe 551 shows how to achieve a high material removal rate while maintaining a reliable cut.

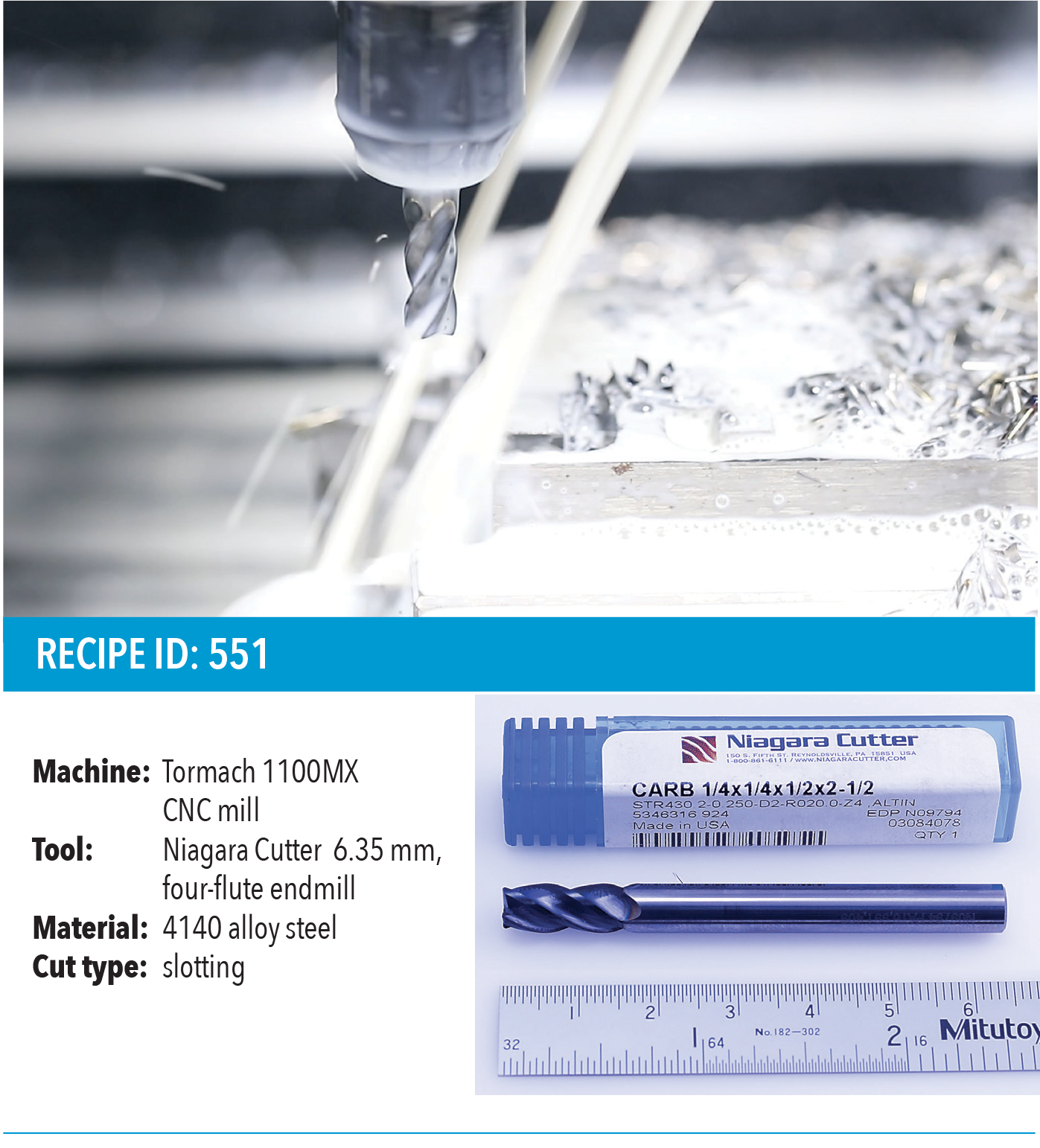

Full-diameter slotting is not the preferred method for removing large amounts of material, but sometimes part geometry makes slotting the best — or only — option. ProvenCut recipe 551 shows how to achieve a high material removal rate while maintaining a reliable cut using a light-duty machine with a 6.35 mm (0.25") endmill to slot 4140 alloy steel.

When developing this slotting recipe, we adjusted the spindle speed, feed rate and DOC with the goal of creating a dependable, productive process. We discovered that maximizing the DOC did not maximize the MRR. Rather, the recipe that achieved the best balance of removal rate and reliability was at a 6.35 mm axial DOC (Ap). The result was an MRR of 15,403.84 mm3/min. (0.94 in.3/min.). Our initial hypothesis that a larger axial engagement would lead to a higher MRR was wrong. Reducing the Ap from 200% to 100% allowed an increase in the feed rate that resulted in a 30% higher MRR.

Two notable differences between the 6.35 mm and 12.7 mm (0.5") axial DOCs are enhanced chip evacuation and the number of radial contact points that an endmill has with the workpiece material. A 6.35 mm axial DOC results in one contact point with the material and produces one chip at a time, whereas a 12.7 mm DOC has two contact points and produces two chips at a time.

More points of contact can help stabilize a tool when using adaptive-style machining strategies with thin radial engagement, also known as dynamic or high-speed machining, but additional points tack on tool pressure. Too many points of contact can increase pressure to the level of causing chatter. With a light-duty machine, reducing points of contact helps minimize the amount of rigidity required for a stable, chatter-free cut.

The 6.35 mm DOC offered superior chip evacuation when compared with the 12.7 mm DOC. This improvement minimizes re-cutting of chips and enables coolant to more easily flush chips, reducing heat buildup and lubricating the cut.

Caution must be exercised when testing slotting recipes as the length of the overall slot and changes in slot direction affect the ability of coolant to access the cut. Any changes in a coolant's aim can lead to tool failure and breakage — often quickly. A 102 mm (4") test slot along one axis is very different from a 508 mm (20") slot around the profile of a part that involves x- and y-axis movement.

Consider recipe 551 for drilling and tapping machines, Bridgeport-size machines or even old vertical machining centers that may not benefit from the higher rpm common with modern machine tools. A larger machine tool with more rigidity or power may yield different results.

To view a video of the slotting operation at www.ctemag.com, scan the QR code with your smartphone or enter this URL on your web browser: cteplus.delivr.com/2n4xt