Automation has become an important—almost essential—part of manufacturing. As new technologies emerge, it is increasingly practical in both cost and implementation for small and large shops alike to embrace some form of automation. Although many kinds of automation are available for manufacturing, one that is becoming popular at machine shops is on-machine probing, as well as the digital technology that drives it.

With on-machine probing, shops can perform part setup and inspection tasks using the same setup and hardware used to machine a part. When combined with a pallet system, which is a form of automation that allows parts to be loaded automatically into a machine, on-machine probing permits a machine tool to run completely unattended.

That said, just as a CNC machine requires an NC program to tell the machine how to cut a part, a machine must be told how to probe a part. There are a few ways to do this. Perhaps the most common method is to have the machine operator perform the probing cycles directly on the machine controller after a new job is loaded. However, this requires the operator to stop the machine and manually probe each part, which does not lend itself well to automation. This approach also increases the risk of user error because the operator must manually enter data, and even simple probing cycles can be quite complicated.

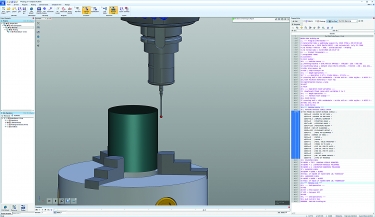

CAMplete TruePath helps users set part data and check stock to ensure that the entire process is ready for automation.

Fortunately, probing cycles can be included as part of an NC program. Manufacturers of on-machine probes provide a set of NC programs, which are installed on a machine’s controller. These programs can be called up as subprograms or cycles directly from an NC program, so probing is performed automatically after a part is loaded. This procedure reduces the risk of operator error and increases the runtime of a machine because it does not need to be stopped to manually probe each part.

But even with probing cycles provided on a controller, successfully creating an automated probing routine requires the right strategy and tools. To prevent an NC program from running if the stock is incorrect, the program should include probing cycles to ensure that the correct stock has been loaded onto the correct pallet. If the stock is right, the NC program needs to include probing cycles to set the datum so the program runs in the proper location.

To accomplish this task, see that probing cycles are programmed using the original CAD data so the values in the probing cycles are accurate. In addition, each probing cycle provides a variety of options, which affect the motion of the probe between probe points. Therefore, before running a program on a machine, proper simulation is essential to protect a probe and machine tool by detecting collisions in a virtual environment and preventing them on the shop floor.

To aid this endeavor, CAMplete TruePath 2019, a post-processing and simulation suite, is adding software support for on-machine probing for select machine tools. With CAMplete TruePath, users can pick which probing cycle they would like to use and select the geometry for the cycle directly from their CAD model. The NC code then is generated and added to a project, which has already been posted by CAMplete TruePath, ensuring that the probing cycle is integrated seamlessly into the NC program. After the posted code is generated, it can be simulated on a machine tool in a virtual environment, guaranteeing that any collisions or errors in the program are caught before they are sent to the machine.

Automation in manufacturing has come a long way and will continue to advance. To take full advantage of what’s available now and what’s to come, you must have the proper tools in place and know how to use them. The right simulation software will help you progress to where you need to be, and it will grow with you as the manufacturing industry and your business evolve.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.