Technological advances in cutting tools, machine tools and toolholders have allowed machinists and manufacturing engineers to increase holemaking efficiency by eliminating the number of tools required to produce accurate holes. High-performance drills are the best example of these technological advances. In the past, it was common for a machinist to spot-drill, drill and then ream to achieve accurate hole geometry. Now, the same hole can be made in a single operation using a high-performance drill.

However, toolmakers don’t always offer a high-performance drill in the needed size. Other times, the machine tool or the machining process cannot support the cutting parameters needed for applying a high-performance drill. In these cases, other tools are needed to achieve the desired hole geometry. Often, reamers prove to be the most cost-effective solution.

Reamer Basics

Reamers are typically applied to enlarge drilled holes, without altering their geometries, while improving hole surface finish.

Reamers are available in numerous styles, including Morse taper, center and tapered reamers, all of which have specialized uses. However, most shops produce close-tolerance, straight-sided (nontapered) holes, so tapered varieties are rare.

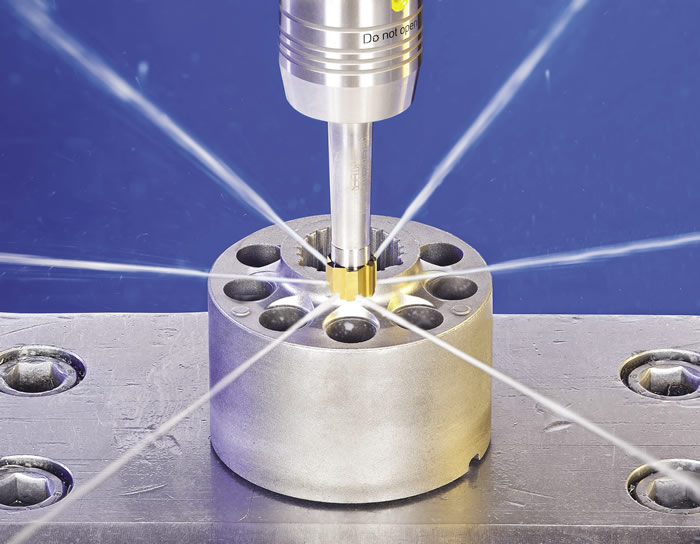

This high-performance reamer from Iscar Metals has replaceable heads, which allow a machinist to quickly renew the tool at the work station. Image courtesy Iscar Metals.

Those familiar with machining and toolmaking are most likely familiar with chucking reamers. They are ubiquitous in machine shops because they are the most economical way to produce close-tolerance holes in both high- and low-volume applications.

The intended use of a chucking reamer is to accurately size close-tolerance holes, which are often for dowel pins, drill bushings and other applications that require an exact fit. Standard chucking reamers can achieve hole-to-hole repeatability of 0.0005" (0.0127mm). A reamer’s flute geometry is what allows the tool to repeat closely. Although they appear to have flutes for cutting, chucking reamers are ground so they cut only on their ends. Like a drill, the flutes are for chip evacuation and coolant flow.

Reamers typically have no fewer than four flutes, which, unlike a drill, work to support the tool and prevent the eccentric rotation associated with 2-flute tools. These features make the tool self-supporting, allowing for excellent repeatability.

In addition to straight flutes, reamers also come with spiral flutes, which offer some advantages over straight flutes in certain applications. A right-hand spiral will pull chips up and away from the bottom of a blind-hole. On the other hand, a left-hand spiral will push chips forward, which is beneficial when reaming a through-hole. In either case, spiral flutes are always recommended when the reamer will intersect another feature, such as a cross-hole or keyway. Spiral flutes prevent the grabbing action that occurs when a straight flute is unsupported by the side of the hole.

Chucking reamers are available in countless sizes, with diameters increasing or decreasing in small increments around nominal sizes. For example, a 3⁄16" (0.1875") reamer can be purchased in the following sizes: 0.1866", 0.1870", 0.1874" and 0.1875". This availability is common for small diameters and allows fine-tuning an operation to deliver the desired hole size. Chucking reamers are such an effective and essential tool that some reamer manufacturers have established grinding cells to offer 24-hour turnaround on specials.

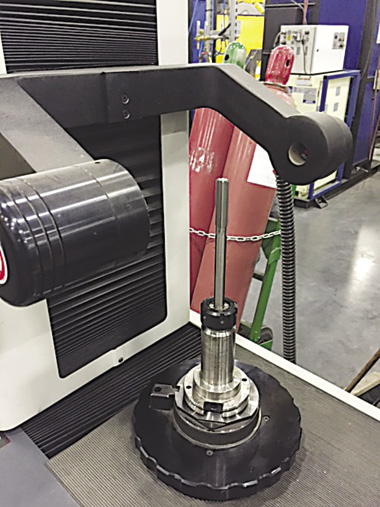

Controlling runout is key to successful reaming. The runout of reamers can be verified with a tool presetter before installing the tool in a machine. Image courtesy C. Tate.

Stepped-Up Performance

When tolerances are very tight, production quantities large or workpiece materials challenging, a chucking reamer may not provide the necessary performance. These situations call for a more sophisticated reamer. Several manufacturers offer specialized reamers under various names, but all can be considered “high-performance” reamers.

High-performance reamers vary in design but share some common traits. Most are capable of holding extremely tight tolerances due to their being adjustable. Adjustment enables the user to remove radial runout from the cutting edge and, in some cases, alter axial runout. Axial and radial runout are the most common reaming problems.

High-performance reamers often have removable cutting edges, such as blades or inserts. They are easily changed and reset, allowing the cutting edge to be renewed at the point of use. While this type of tool is typically more expensive than the traditional styles with ground flutes, the ability to renew the tool at the machine provides significant cost savings, because they do not need to be shipped to a sharpening service.

Not all high-performance reamers can be adjusted. Some have fixed cutting edges and require special equipment to recondition the cutting edge. These tools and reconditioning them are expensive. However, high-performance, fixed-edge tools can produce a large number of holes before needing to be reconditioned, which makes them economical in high-volume operations as they are typically made of materials like carbide, PCD or PCBN.

High-performance reamers often have some type of guide pad installed. This pad stays in contact with the wall of the hole to support the tool, allowing more aggressive machining parameters by preventing runout and chatter.

No matter which kind of reamer you are considering, the best way to determine the most suitable tool is to discuss the job with several toolmakers. If possible, test the tools in your facility, and, if testing is not an option, ask the manufacturer for a performance guarantee.

Contact Details

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- reamer

reamer

Rotating cutting tool used to enlarge a drilled hole to size. Normally removes only a small amount of stock. The workpiece supports the multiple-edge cutting tool. Also for contouring an existing hole.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.