An ongoing problem for shops is finding burrs, foreign objects and debris (FOD), and other defects in their finished parts. This is especially the case when defects not only are costly but present risks to health and safety.

All Axis Robotics has solved this problem by developing the Automated Burr/FOD and Defect Detection System, which uses collaborative robots from Universal Robots A/S, Odense, Denmark.

Founder and CEO Gary Kuzmin said motivation for developing the system came when sister company All Axis Machining built a complicated aerospace product for a customer that needed the parts to be free of all burrs and rolled edges. The company thought that it had met the specifications, but the customer—which had 20 QC inspectors for incoming products—expressed concern about burrs that could dislodge, causing system failure.

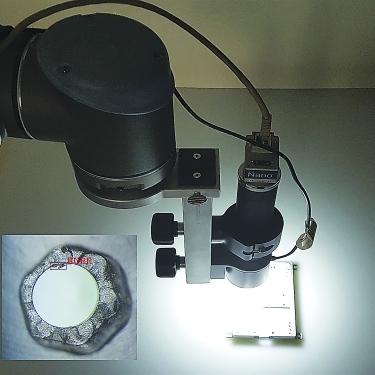

All Axis Robotics has made it easier to detect burrs, foreign objects and debris, and other defects. Image courtesy of Axis Robotics

In response, All Axis upgraded its inspection microscopes. But it realized that operator fatigue becomes a factor after about 20 minutes when conducting manual inspection. “Once fatigue sets in,” Kuzmin said, “you’re not as sharp detecting burrs, FOD and other defects.”

All Axis then added employees to develop systems and supporting software. Two years later, the company had a new system for detecting burrs. “As we developed the product,” Kuzmin said, “we realized it wasn’t only capable of detecting burrs but also of detecting defects and anomalies in a whole class of undesirable artifacts left over from the manufacturing process.”

These defects included rolled edges, improperly installed hardware, tangs in the helicoils, missing hardware and material defects, such as cracks and poor gasket integrity.

To create the system, the company decoupled the microscope and attached the magnifying portion, or camera, on the end of a cobot. The robot mimics human movement in terms of rotating the part. That movement is now embedded in the robot.

“Once the robot has honed in on the location, it records the polar coordinates of where the defect is,” Kuzmin said. He likened the recording process to programming a CNC machine, except using polar coordinates instead of linear ones.

When the software detects an anomaly, the robot records it, essentially mapping the defect. The operators then use this information to go back and manually correct the defect or work with other software to make the correction.

In general, the system can scan about 7" per second, according to All Axis, recording in real time. Several factors affect speed, including the type of computer system and graphic processing used to complement the robot. “We may need to upgrade to speed up the processing for larger parts,” Kuzmin said. “The camera is indexing itself; it’s taking an image within a field of view.”

He added that speed also depends on the area of inspection. “You don’t necessarily need to scan the entire part but only the area where the problem may be.”

Although the system was originally developed for internal use, it’s now being marketed to other companies, including those working with plastics and composites. “At the end of the day,” Kuzmin said, “whether you’re in aerospace, defense, medical or even high-end circuit board manufacturing, one burr can create a failure. Our goal is to prevent those failures.”

For more information about All Axis Robotics, Dallas, call 972-312-8609 or visit www.allaxisrobotics.com.

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- fatigue

fatigue

Phenomenon leading to fracture under repeated or fluctuating stresses having a maximum value less than the tensile strength of the material. Fatigue fractures are progressive, beginning as minute cracks that grow under the action of the fluctuating stress.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.