The Beach Boys may have celebrated “Good Vibrations,” but people who work in the machining industry will agree that the best vibrations are no vibrations.

Mass dampers traditionally have been used to reduce vibration when turning. These dampers must be tuned appropriately, however, to account for such factors as cutting speed, tool wear and the workpiece material. As a result, operators must frequently stop the machines to reset the dampers, leading to a variety of inefficiencies in the process.

These concerns have been addressed with the introduction of the Self-Tuning Mass Damper by Stockholm-based MAQ. The key to the STMD is its design. The impetus came when Qilin Fu, MAQ’s co-founder and CEO, was a doctoral student at KTH Royal Institute of Technology in Stockholm. He studied how vibration affected machining and realized there were opportunities for improvement.

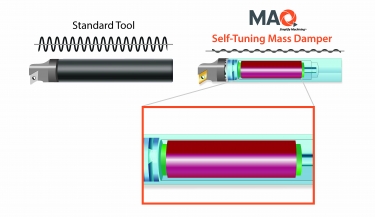

Polymer discs inside the STMD react and adjust to changes in vibration. Image courtesy of MAQ

“We had a breakthrough in 2015,” Fu said. “Using existing polymers, my colleagues and I developed methods for accurately measuring a polymer’s frequency-dependent stiffness. We found that some polymers have a substantially increased stiffness with increased frequency.”

Eventually, the team determined that a group of polymers, having a particular physical structure and chemistry, will exhibit the required frequency-dependent stiffness for mass damper applications.

Machine tools vary in size and age, and these variables influence vibration. A typical mass damper has to be tuned for each combination of those factors. The STMD is different because of the adaptability of its polymers. Inside the tool is a tungsten mass supported by polymer discs. The discs react to changes in vibration, changing their own stiffness in response and maximizing their damping effectiveness.

The STMD’s combination of polymers plays an important role with a key metric that affects vibration: the length-to-diameter ratio. Turning tools are set at different lengths based on the materials being machined. MAQ’s tests have shown that as the length-to-diameter ratio increases, the STMD is increasingly effective versus competitors in controlling the vibration amplitude.

The STMD is essentially plug and play, according to the company. MAQ offers the STMD in a variety of length and diameter combinations, in both metric and inch dimensions and with different-size cutter heads.

The company is growing its product line, Fu said, and is also developing tools for milling and holemaking applications. He added that MAQ wants to work with customers who need different dimensions. “We want these customers to challenge us with their custom dimensions.”

Francois Gau, MAQ’s chief marketing officer, elaborated on the quality and economic benefits. Minimizing vibration enhances the surface finish while reducing scrap and energy costs. Tool life increases because of more efficient use and less wear. These efficiencies, along with time saved from frequent tool changing, significantly lower cycle time.

“All in all,” Gau said, “the STMD can help our customers reduce their total cost of ownership by as much as 30 percent.”

For more information about MAQ, call 724-875-5358 or visit www.maqab.com.

Contact Details

Related Glossary Terms

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.