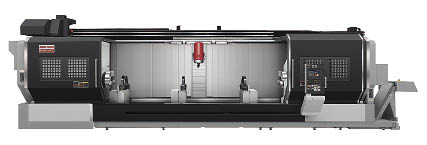

Courtesy of Mori Seiki U.S.A.

Multitask machines, such as this Mori Seiki NT6600 DCG mill/turn center, require careful planning prior to installation and creative reimagining of machining processes.

Over the past several years, the growing prevalence of multitask, or mill/turn, machines has caused many shops to consider investing in the technology to maintain or improve their competitive edge. As with any innovation, successful implementation of multitasking requires a shift from conventional thinking.

In looking at companies that have adopted multitasking, the greatest success stories have inevitably arisen from manufacturers that carefully planned for its integration and creatively reimagined their machining processes. Enough shops have successfully multitask machined that it is possible to construct a guide to maximizing the technology’s benefits.

The Right Choice?

Some of the best applications of multitask machines come from the aerospace and energy industries. Multitasking is certainly not limited to those fields, but the large, complicated parts produced for aircraft, power generation and oil field applications embody many of the features for which multitasking offers significant potential for improvement.

For large parts that require internal and external machining, multitask machines allow producing a completed part with a single setup on a single fixture. End users obtain several benefits by eliminating the need to move a part through processes on more than one machine. Productivity receives a significant boost, because part handling time is minimized. A shop’s work flow can also be simplified and improved, as parts do not have to be scheduled for time across various workstations. Accuracy can also improve, as each refixturing of a part creates an opportunity to introduce error.

Manufacturers that understand and utilize a B-axis-type multitask machine also stand to experience significant gains. Effective use of a B-axis allows machining of highly complex parts.

On the other hand, not every job is well suited for a multitask machine. Typically, high-production runs of relatively simple, standardized parts are most efficiently manufactured by expensive, dedicated, specialized machines that can produce them very quickly. In those instances, there will be little or no benefit from multitasking, and it may even diminish productivity.

The same can be said of jobs where production is already optimized. In some instances, a twin-spindle, twin-turret machine provides quick process times and, despite the much longer setup times, will be the optimal process for parts requiring large production runs. Determining the best way to machine a part requires careful evaluation of the part’s complexity and understanding how differing machine technologies will machine it.

Preparing Employees

Once a shop has decided to integrate a multitask machining center into its operations, successful implementation will depend largely upon selecting or hiring the right employees to program and operate the machine and providing them with the proper training. Too often, a manufacturer selects someone especially strong in milling or turning, but with little practical experience in the other discipline. As a result, the shop may fail to realize the equipment’s true benefits.

Ideal candidates to work with a new multitask machine are those with a broad base of machining experience. Significant experience in both turning and milling should be required and exposure to ancillary processes, such as gundrilling and gear cutting, can provide a significant edge as well. The ideal candidate is well-rounded and most likely would have filled the position of toolmaker in the shops of yesteryear.

The candidate should also have the imagination needed to program a multitask machine. A multitask machine—with a large Y-axis travel, a spindle on the B-axis that can move at different angles and a full C-axis—can operate in entirely new ways. The ability to conceptualize the machine’s potential is vital to developing programs that take full advantage of its capabilities. If an ideal candidate does not immediately come to mind, a shop might consider using aptitude tests that measure visualization skills.

Once a shop has determined which employees will take ownership of programming and operating a new multitask machine, in-depth training from the machine tool builder is essential. Valuable education can also be obtained from manufacturers of ancillary products, such as cutting tools and software. Toolmakers, in particular, can offer substantial value. That’s because they often develop tools specifically for multitask machines.

Tooling Considerations

While there are various tools for multitask machining, expertise in three specific categories is vital. True mastery of combination, miniturret and turn/mill tools will only come through comprehensive training and experience, and there are several key concepts that should be understood about each of them.

As the name implies, combination tools are multifunctional, combining turning and milling in a single tool. Such a tool can be indexed to a number of positions to allow stationary turning or rotated to mill. As the tool is set up, operators must understand how to write the offsets for its operation. Instead of setting one offset for the tool, individual offsets must be set for each operation.

Miniturret tools allow multiple cutting heads and blades to be placed in a single tool location. The miniturret is indexed to apply specific inserts for turning, threading or grooving. Again, setting a separate offset for each tool is required to take advantage of the system, as is programming the miniturret to index to the correct position for each operation.

With turn/mill machines, the two processes are combined and a rotating tool is applied to a rotating part. Offset comes into play yet again with turn/mill tools because different values must be used for wiper inserts and round inserts. The tool must be offset from the centerline of the C-axis rotation or the cylindrical diameter being cut. To obtain high productivity and fine surface finishes, the centerline of the cutter must be positioned properly to maximize tool performance.

If the proper steps are taken, from ensuring the technology’s applicability to selecting and training the right operators and programmers, multitask machining provides a competitive advantage. It can help negate the dual impact of cheap foreign labor and a shrinking skilled domestic workforce. Productivity increases and a greater level of flexibility result. CTE

About the Author: Jim Grimes is product manager, machine investments for Sandvik Coromant Co., Fair Lawn, N.J. For more information about the company’s cutting tools for multitasking and other tools, call (800) 726-3845 or visit www.coromant.sandvik.com/us.

Related Glossary Terms

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- gundrilling

gundrilling

Drilling process using a self-guiding tool to produce deep, precise holes. High-pressure coolant is fed to the cutting area, usually through the gundrill’s shank.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.