CNC lathes have evolved greatly over the past few decades. What were once simple 2-axis turning machines have become a bewildering array of extremely capable metalcutting equipment, most of which offer two spindles, multiple turrets, robust milling capabilities and can complete many parts in a single setup.

In other words, they have become multitask machines.

Despite the obvious benefits, however, many parts manufacturers look at the $500,000 price tag of a multitasker and cringe. They can buy three or four conventional lathes or machining centers for that amount and, therefore, crank out more work and eliminate the eggs-in-one-basket worry of a single supermachine breaking down and bringing production to a standstill.

They might also look at a tool-changing, multispindle, live-tool machine and wonder who’s going to run the darned thing. Good machinists and programmers are in short supply—good luck hiring one that can set up a machine with eight or more axes, dozens of tools and the crash potential of a stock car race. With its complexity and high price, multitasking is perceived by many in the machining world as a headache that should be avoided. Not so, say sellers of multitask machines.

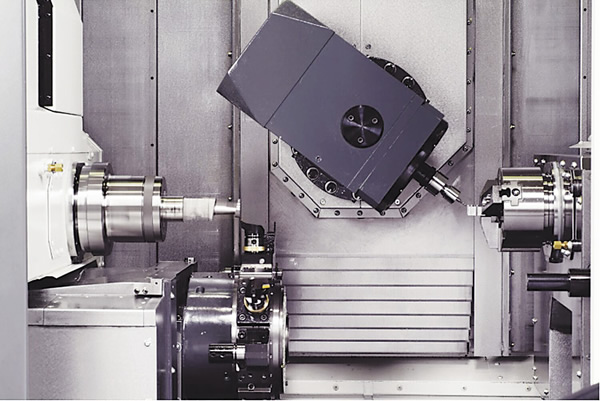

An INDEX R300 turn-mill center performs simultaneous 5-axis machining on the main and counter spindles. Image courtesy INDEX.

Goodbye, Old School

Robert Appleton, applications manager for Doosan Machine Tools America, Pine Brook, N.J., said there are many reasons to maintain the machine tool status quo, but—in most cases—multitaskers produce more-accurate parts in less time, make better use of available floor space and provide greater flexibility than conventional machine tools.

“This is especially true for job shops,” he said. “You never know what’s coming through the door. With a multitasking machine, you can quote pretty much anything that fits on the machine and have confidence you can get it done quickly.”

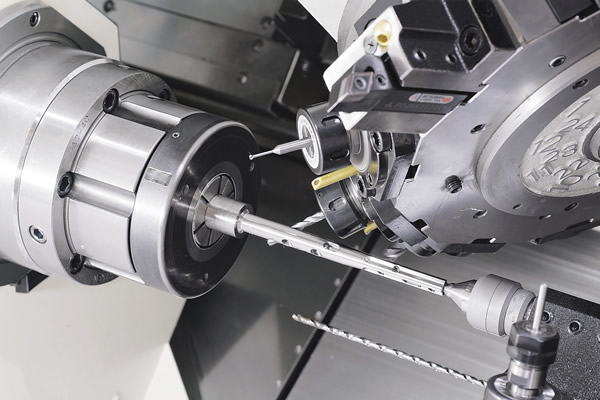

Machining long shafts and deep holes are just two of the possibilities with this twin-turret, live-tool, B-axis multitask machine from Methods Machine Tools. Image courtesy Methods Machine Tools.

Furthermore, the notion that shops will be unable to find qualified operators is false, Appleton said. Aside from the occasional engine lathe or manual mill operator who’s new to CNC machining, most on the shop floor acclimate quickly to the challenges of multitask machining.

“Most of these machines are really nothing more than two lathes with a machining center on top,” Appleton said. “If you can break the programming and setup into smaller pieces, tackling the part one machining process at a time, it comes together pretty naturally. Typically, we figure from 2 to 4 months and the customer will be up and running and well on their way.”

Appleton said the steepest part of the learning curve with multitaskers is rethinking part processing. Gone are the days of worrying whether the part will collapse during the second operation, wondering how to clamp it on a machining center. No more work in process or scrapping hundreds of parts on the final operation.

Multitaskers can often machine parts, such as this aircraft landing gear strut, in a single setup. Image courtesy Doosan Machine Tools America.

“It may seem ironic, but machining is much simpler with a multitasker,” he said. “You load some bar stock or chuck a sawed blank, push cycle start and a few minutes or half an hour later out comes a finished product. Part handling and human error are virtually eliminated with a multitasking machine. Best of all, we find pretty consistently that parts are completed in about half the time.”

Cash is King

“With conventional machine tools, you typically have a couple of lathe operations, then the job heads to the milling department,” said Rich Parenteau, director of applications development at Methods Machine Tools Inc., Sudbury, Mass. “The parts have to wait in between machines, so there’s work in process sitting around. You have to build fixtures, pay for material and employees. The entire process takes weeks and often much longer.

“With a multitasker, the part comes out of the machine, you wash it, pack it, ship it and invoice it the same day. Not only is it more efficient, but you’re getting paid quicker. For small shops especially, this is a big boost to cash flow,” Parenteau said.

He agreed that multitask machine setup and programming is nothing to fear. Many machines have onboard CAM software with simulation capabilities, so potential collisions are easy to spot. A variety of M codes and other functions exist, making synchronization of the various machine axes—and commensurately shorter cycle times—simpler to achieve. Finally, elimination of multiple fixturings makes it easier to meet tight tolerances.

“Geometric and dimensional part tolerances are tighter than ever,” he said. “Feature to feature, hole to hole, concentricity, roundness—it all becomes more difficult when you’re tumbling a part across four or five operations. Also, if you don’t have to worry about locating on a journal or bore, then there’s no need to hold tighter tolerances on that feature than what’s called for on the drawing. Multitasking avoids all that.”

Cost per Part

Despite the benefits multitasking machines provide, their high price tags raise concerns that must be addressed. Jeff Reinert, president of INDEX Corp., Noblesville, Ind., said one of his customers wrote a letter to his employees, explaining his decision to invest $500,000 in a multitask machine.

“Compared to an older machine that was already paid for, [the customer] calculated the additional payment would cost the company $6.80 per hour, assuming round-the-clock operation for a period of 10 years,” Reinert said. “Time studies showed the multitasking machine was three times faster. With a shop burden rate of $50 per hour, parts that cost $2.50 to make on the old equipment could be produced on the multitasker for $0.97 apiece. Even with a more-conservative 50 percent productivity improvement, the new machine put an additional $0.61 per part in the company coffers.”

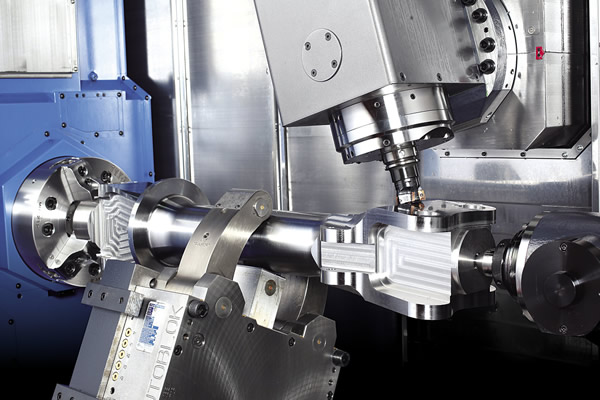

Some multitask machines, such as the Nakamura-Tome NTMX from Methods Machine Tools, use a machining center-style B- and Y-axis milling head with a toolchanger in lieu of an upper turret. Image courtesy Methods Machine Tools.

Why not buy five commodity machines for $100,000 each, then, and machine the parts in one-fifth the time? That is the sort of thinking manufacturers have been trained over the decades to take as gospel—that the lowest-cost CNC spindle equals the lowest-cost part.

However, Reinert pointed out that a number of factors besides machine cost impact part profitability.

Compared to a multitask machine, five conventional machines require roughly five times as much floor space, maintenance, tooling and employees,” Reinert said. “We have to stop thinking about the machine cost alone, because it’s basically irrelevant in most situations. The most cost-effective solution is the one that makes a good part in the shortest amount of time with the smallest machine footprint. That’s where multitasking machines really shine.”

Multitasking in St. Michael

Chad Weigel, CEO and director of operations for Iker Manufacturing, a small but growing job shop in St. Michael, Minn., said he’s seen a 40 percent improvement on nearly every part machined on the company’s Mazak Hyper 150 MSY multitask machine.

“We’ve always been a Swiss shop, which I consider multitasking, but the new breed of CNC mill-turn lathe offers more capabilities and overall flexibility compared to our conventional machine tools,” he said. “It’s a perfect fit for our corporate goals.”

Those goals include e-commerce-like flexibility, where a customer can order complex parts online one day and have them delivered the next. “I think multitasking and similar machining technologies are the future of our industry,” Weigel said. “Manufacturers should have the ability to accept an order electronically and have the job go directly to the shop floor, where a complete part is quickly kicked out and shipped off to the customer. The only way you’re going to do that is with multitasking equipment.”

The Mazak is an important part of that equation. With twin turrets, Y-axis milling capability and the ability to apply up to 144 tools, Weigel said there’s little the machine can’t handle. Mastering all that newfound multitasking potential doesn’t happen overnight, however. Two years after the machine was installed, the shop is still finding new ways to improve cycle times and take full advantage of the machine’s capabilities.

“When you get up into higher volumes, it’s important to balance out the cycle time between the two spindles. It’s no different than on a Swiss machine, where you try to get as many tools as possible in the cut at one time,” he said. “That’s something we’re continually working on, but the Mazatrol control makes it fairly easy. We also like that the machines are virtually impossible to crash, unless you intentionally disable the safety barriers, of course. That’s an important feature when you’re talking about a half-million-dollar machine.”

Weigel already placed an order for a second, similar multitask machine, and offered some advice for would-be multitaskers: “Make sure to align yourself with a knowledgeable machine tool distributor. There’s a lot to know about processing parts on these machines. The technology is still new enough that some distributors don’t have the necessary expertise, and customers end up running an expensive multitasker as if it were a regular lathe or mill. Without the right partner, they don’t get the full functionality out of their equipment.”

—K. Hanson

Contributors

Doosan Machine Tools America

(973) 618-2500

www.doosanmachinetools.com

Iker Manufacturing

(763) 428-0020

www.ikermfg.com

INDEX Corp.

(317) 770-6300

www.indextraub.com

Methods Machine Tools Inc.

(877) 668-4262

www.methodsmachine.com

Contact Details

Contact Details

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- multifunction machines ( multitasking machines)

multifunction machines ( multitasking machines)

Machines and machining/turning centers capable of performing a variety of tasks, including milling, drilling, grinding boring, turning and cutoff, usually in just one setup.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.