When it comes to highly accurate machining technology, jig boring is better. So say proponents of the century-old machining technique.

In the early part of the last century, jig boring started as a better way to make holes. But the technology has since evolved into a more-versatile machining option.

A conventional jig borer is a machine tool for boring highly accurate holes. “With higher-quality machining centers, you can look at achieving tolerances of 20µm in the work zone. But when you need to go beyond that—down to 10µm, 5µm or even 2µm—that puts you into the realm of a jig boring machine,” said Tom Dolan, vice president of sales and marketing for jig-borer builder Mitsui Seiki USA Inc., Franklin Lakes, N.J.

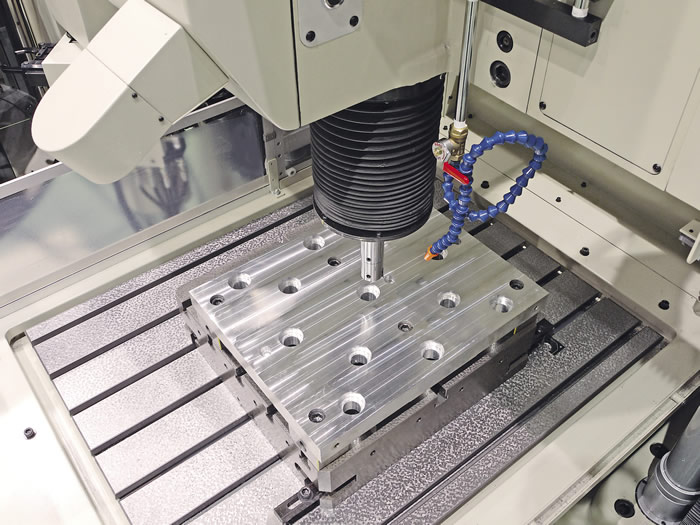

Manufacturers of mold bases use jig boring and jig milling machines to finish bores with tolerances tighter than 5µm in roundness, perpendicularity and straightness. Image courtesy Mitsui Seiki USA.

To achieve the required level of precision, jig borers are designed and built in ways that set them apart from typical machines. For example, jig borers feature components made with tighter-than-normal tolerances, as well as improved rigidity, thermal stability and vibration-damping capabilities, according to Dolan.

What’s more, jig borers are made to maintain their accuracy for long periods of time. Dolan said it’s not unusual for a jig borer to remain exceptionally accurate for 20 years or more.

Because of their superior accuracy, jig borers are used to make parts for machine tools, which is why they’re often referred to as “mother machines,” Dolan said. Other applications include making parts for the aerospace, defense, optics, and mold and die industries.

On the downside, jig borers are not built for high-speed machining. Though much more accurate than a typical machining center in terms of positioning capability, jig boring is a slower process, Dolan explained.

Nonetheless, jig-borer productivity has gotten a boost in recent years from control technology. Fifteen years ago, Dolan said, visitors to a manufacturing facility where jig boring was done wouldn’t have been surprised to see only manual jig borers—or, at best, machines with simple MDI (manual data input) controls. Since then, however, CNC jig boring machines have become the norm, he said.

Another important advancement is the so-called jig milling machine, which has taken jig boring technology beyond its traditional roles of holemaking and light-duty milling.

Though it can be thought of as a specialized type of milling machine, a conventional jig borer features a quill or headstock that cannot handle the significant side loading generated during normal mill work. Jig mills, however, usually lack a quill but can still perform jig-borer tasks and milling operations that are beyond the capabilities of conventional jig borers. This ability to perform more than one task can eliminate the need to move a workpiece from one machine to another, saving time and improving part accuracy.

Jig mills can hold tighter tolerances than a typical milling machine, though perhaps not as tight as those held by a conventional jig borer, Dolan said.

Not willing to make accuracy compromises? Then consider the Yasda YBM-Vi40 5-axis jig mill. The machine “can do 3-, 4- and 5-axis milling with the same accuracy as a traditional jig borer producing a straight-line hole,” said Stephen Previti, Yasda product manager for Methods Machine Tools Inc., Sudbury, Mass., a machine tool importer of Yasda machines to North America. What’s more, Previti added, “no jig borers have the spindle construction that will take a side load like the Yasda will.”

Accuracy-boosting Vi40 features include a rigid worm-gear mechanism and a thermal-displacement system that circulates temperature-controlled oil through the machine body to minimize thermal displacement. In addition, the machine’s performance is enhanced by more than 400 hours of hand scraping, done to enable precise machine movements, said Jeffrey Johnson, Yasda mold and die project manager for Methods.

According to Johnson, the Vi40 can perform complicated jobs involving high-value parts made from materials like titanium and Inconel, while lowering scrap and labor. And in moldmaking applications, it can eliminate the need for “very laborious” EDM or grinding operations.

Contact Details

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring machine

boring machine

Similar to a turning machine except that the cutting tool (single-point or multiple-cutting-edge), rather than the workpiece, rotates to perform internal cuts. However, boring can be accomplished by holding the tool stationary and turning the workpiece. Takes a variety of vertical, slanted and horizontal forms, and has one or more spindles. Typically a large, powerful machine, it can readily hold tolerances to 0.0001". See jig boring; lathe; turning machine.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- jig

jig

Tooling usually considered to be a stationary apparatus. A jig assists in the assembly or manufacture of a part or device. It holds the workpiece while guiding the cutting tool with a bushing. A jig used in subassembly or final assembly might provide assembly aids such as alignments and adjustments. See fixture.

- jig boring

jig boring

High-precision machining (a sophisticated form of milling) that originally pertained to jig and fixture manufacturing. Basic jig-boring processes include centering, drilling, reaming, through and step boring, counterboring and contouring.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- milling machine ( mill)2

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.