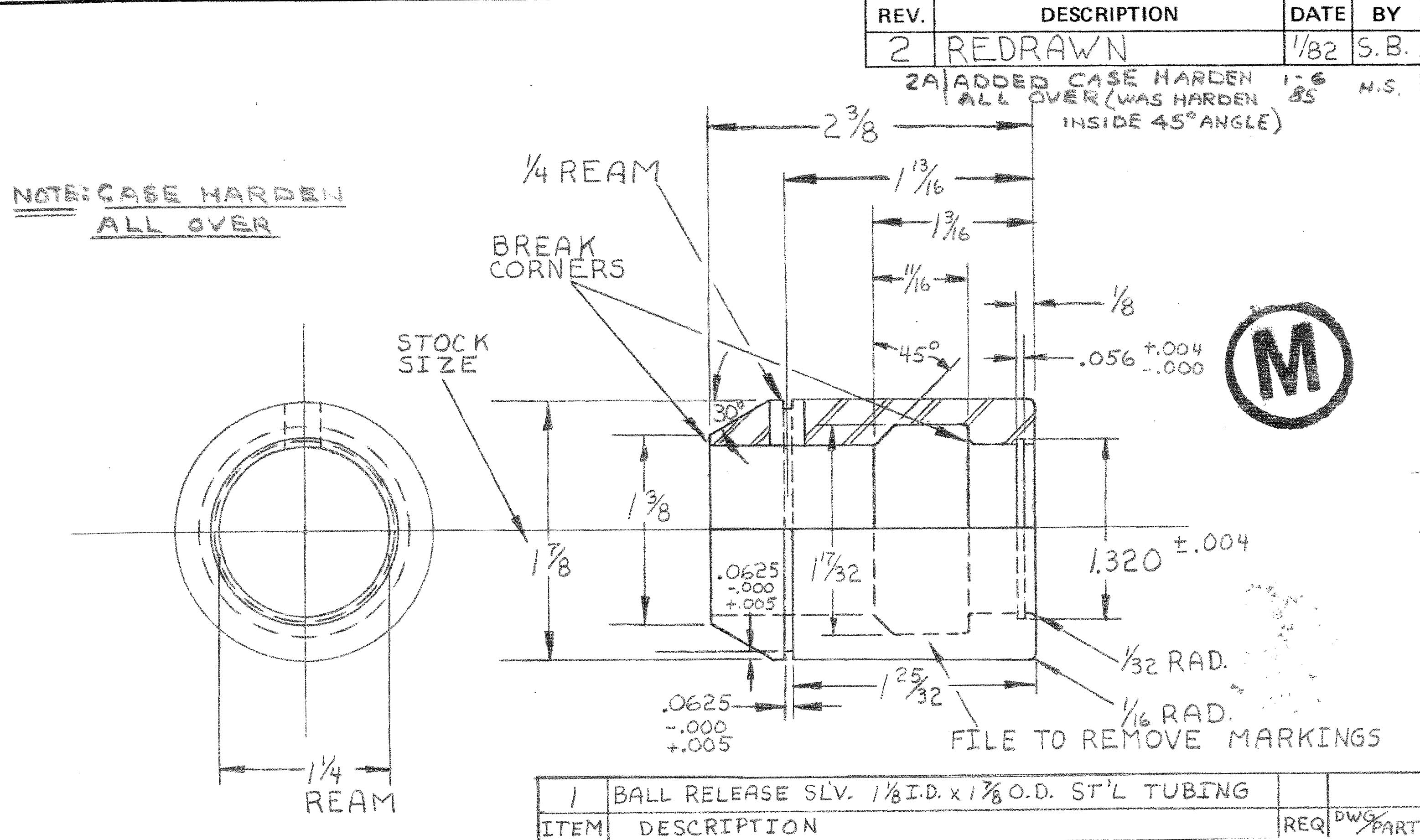

Spring calipers have been around for a hundred years and, like micrometers, still have a place in the metrology arsenal. It’s my understanding that some in the machine shop world don’t know what these measurement tools can do, so this is a primer. The drawing shows a part that I make repeatedly, and, yes, the last revision to this drawing took place in 1985, which kind of dates me. The part has internal and external snap ring grooves and an internal cavity for steel balls. The diameters of these three features can be measured with spring calipers. I like to measure parts in process, and that’s what I’ll talk about here.

Blade micrometers are available that can measure the external groove with high accuracy, but this part doesn’t need that accuracy, and I find spring calipers to be quicker. For the internal features, there are more expensive tools that can be used, but I don’t see their advantage.

Let’s look at what spring calipers are. They take some skill to get good, consistent measurements, but demonstrating skill is what machinists do. These tools have a pair of legs held on a journal by a compression spring at one end. The included angle between the legs is adjustable by means of a threaded rod and adjusting nut. The ends of the legs away from the journal perform the measurement. There are two types: one for external measurements and another for internal measurements. External calipers have blade ends facing inward that can fit in external snap ring grooves. Internal calipers have small-diameter ends that are bent outward so they can fit in internal grooves. Like micrometers, spring calipers are available in a range of sizes.

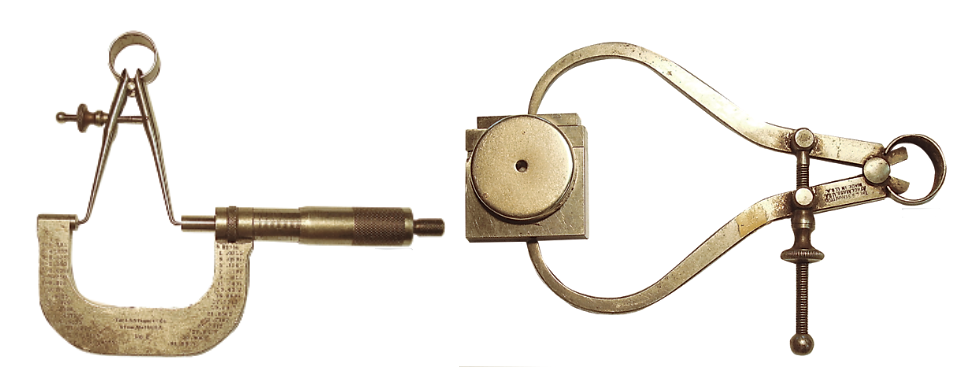

When measuring internal grooves or other features that have diameters larger than the ID at the ends of the part, the procedure is to put the caliper ends in the groove. Adjust the measuring nut so the feel is right, then compress the legs without moving the nut. Next, retract the caliper from the part, release the legs so they go back to the dimension they were at in the groove, and then measure the caliper with a micrometer or other means. The first photo shows an internal caliper being measured by a micrometer.

Measuring external grooves is simpler. Put the blades of the caliper in the groove and adjust the nut to feel, then measure the distance between the caliper ends with gauge blocks. Here’s a tip: Gauge blocks are made from 400 series stainless steel and can be hardened by heat treatment. As 400 series stainless is magnetic, a stack of blocks can be held together with a magnet. A button magnet is great for this and keeps your block stack together. The individual blocks don’t get lost, and the stack is a lot easier to handle. In the other photo, an external caliper is being gauged by a three-block stack. The blocks are held together by a ceramic button magnet.

To measure a groove in a production environment, you can have a pair of calipers set for a go and no-go measurement scenario. The calipers have a ball on the end of the threaded rod. Take the ball off (it’s threaded) and put a jam nut against the adjustment nut. Quick, cheap and easy.

Related Glossary Terms

- included angle

included angle

Measurement of the total angle within the interior of a workpiece or the angle between any two intersecting lines or surfaces.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- micrometer

micrometer

A precision instrument with a spindle moved by a finely threaded screw that is used for measuring thickness and short lengths.