Dear Doc: When grinding nickel alloys, I occasionally get tiny aluminum-oxide particles embedded in the workpiece. It’s infrequent but unacceptable. What can I do?

The Doc replies: You’re venturing into uncharted territory. This is a problem I hear about occasionally, but I’ve never seen a good solution or good study that explains it — just a lot of half-baked theories. Since it’s infrequent, determining whether process changes had an effect can take months. Having said that, here’s what I tell my customers.

First, look at the possible causes. After diamond dressing, the tips of the Al2O3 grits are somewhat fragile and “crumbly.” Immediately upon first contact with the workpiece, the wheel loses 3 to 10 µm (0.0001" to 0.0004") off the radius as the tips of the grits break off. This loss matters because you don’t want to finish or spark out with a freshly dressed wheel. Otherwise, you run the risk of these crumbling grit tips embedding in the workpiece. You want to leave at least 10 mm2 (0.016 in.2), which is the depth of grind times the length of grind, of material for finish grinding.

This crumbly clean-up period is especially relevant if you’re performing continuous dress. Here, you don’t want to use CD during finishing or sparking out as the wheel will be crumbling off tiny pieces at the end of grind — a bad idea.

Second, examine the type of Al2O3. Theoretically, a tougher, or less friable, grit is less prone to break into small pieces and embed itself in the workpiece.

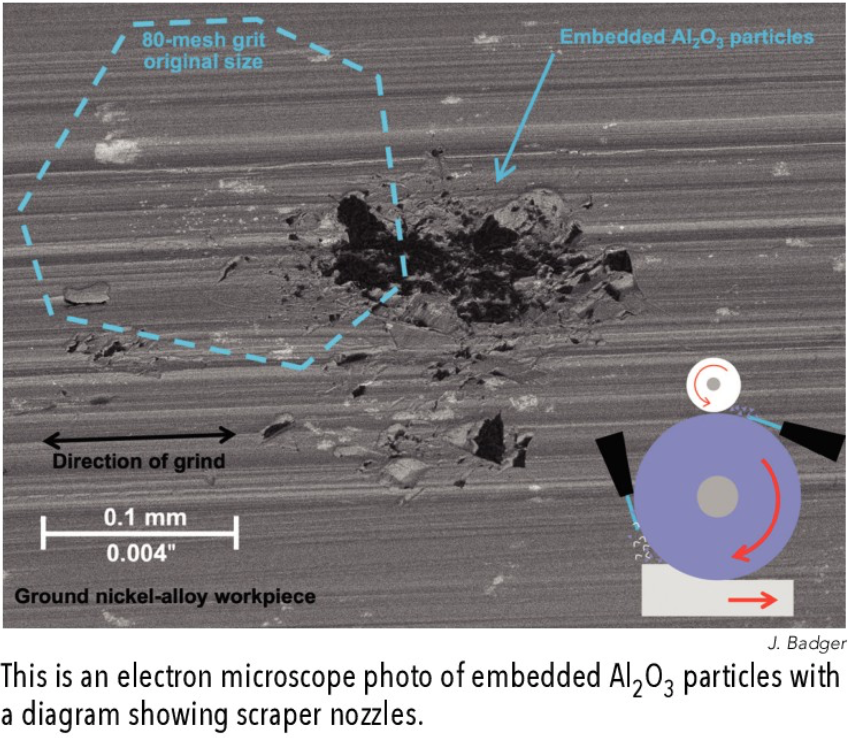

Third, consider putting a flushing nozzle at the exit point when grinding — and at the exit point of the dresser if you’re performing CD — to prevent swarf and busted-out grit particles from traveling with the wheel and returning to the grinding zone, as shown in the image. Unlike a cleaning nozzle, which needs to be over 50 bar (725 psi), the flushing nozzle doesn’t have to be superhigh pressure. Just match the wheel speed, with the direction of the nozzle “scraping” away the swarf as it comes off the wheel.

Fourth, some people — usually the guys who sell filtration systems — swear that poor coolant filtration is the source of the problem. I’m not convinced that’s the cause, but the theory holds water. If Al2O3 particles come out of a nozzle and enter the grinding zone, they can embed themselves into the workpiece.

Fifth, one could argue that simply having better cooling in the main arc of cut would help flush away particles. Aim coolant at the wheel/workpiece interface, and have the wheel velocity equal to the coolant velocity.

Sixth, a gentler grind, especially during finishing, will decrease the risk of fracturing the grit or busting it out of the bond and getting crushed in the arc of cut.

Finally, a harder-grade wheel could help by keeping entire grits from breaking out of the bond material and getting crushed in the arc of cut. On the other hand, a softer-grade wheel could help by allowing the entire grit to break out instead of fracturing into small pieces and becoming embedded. I lean toward a harder grade — and a tougher grit.

Imperfect as it is, that’s my expert opinion. Let me know what happens.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- spark-out ( sparking out)

spark-out ( sparking out)

Grinding of a workpiece at the end of a grind cycle without engaging any further down feed. The grinding forces are allowed to subside with time, ensuring a precision surface.

- swarf

swarf

Metal fines and grinding wheel particles generated during grinding.