Take one company’s leadership in software that provides advanced 3D measurement programming and inspection. Then take a second company’s leadership in robot-based, 3D automated dimensional inspection. Combine the two, and you get the future of automated QC.

In this case, the software is provided via the Metrolog X4 i-Robot packages from Metrologic Group, a developer of 3D metrology software. The software is integrated with the CUBE-R from Creaform Inc., which manufactures 3D portable measurement equipment.

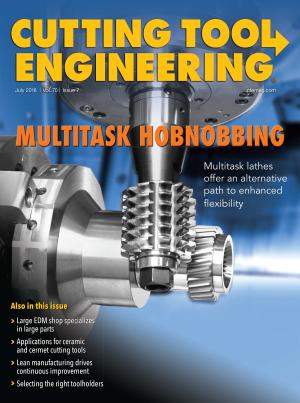

The CUBE-R provides a flexible plug-and-play alternative to CMMs. Image courtesy of Creaform

The CUBE-R is ideal for manufacturers that want to conduct automated QC on the shop floor, according to Stéphane Auclair, division vice president for marketing and product management at Creaform-AMETEK. A central element of the CUBE-R is the MetraSCAN 3D-R, a powerful metrology scanner mounted to a robot.

In turn, Metrologic’s software guides the MetraSCAN 3D-R, determining the most efficient positioning of the sensor and identifying the best trajectories for the robot.

The joining of the software, sensors and robot enables the CUBE-R to provide both speed and volumetric accuracy. This leads to a sizable increase in productivity, Auclair said, especially when dimensionally measuring parts from 1m to 3m long.

Bertrand Gili, president of Metrologic Group, listed a number of benefits resulting from the integrated technologies. Among them are multitasking capability, efficient 3D measurement, automatic field calibration, minimum operator training, a complete turnkey solution and a smaller factory footprint.

The CUBE-R can inspect several hundred parts per day. Data is continuously gathered and analyzed at the same time. The software can handle the large point clouds generated by 3D scanning. As a plug-and-play alternative to coordinate measuring machines, the CUBE-R requires a space of only 4.1m × 4.1m × 3.1m.

Furthermore, because the Metrolog X4 i-Robot and Silma X4 i-Robot software suites provide the calculations needed to guide the scanner and generate accessible reports, they enable the CUBE-R to be easily operated by nonspecialists, Gili said.

For more information about Metrologic Group, Meylan, France, visit www.metrologicgroup.com or call (248) 504-6200. For more information about Creaform Inc., Lévis, Quebec, visit www.creaform3d.com or call (888) 381-0039.

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.