Most people in industry have heard stories about cutting oils catching fire in shops. One occurred at the production facility of a cutting tool manufacturer that was gutted after the oil in a grinding machine caught fire. Another was at a machine shop, which had an oil-mist collector on a Swiss-style machine go up in flames.

The use of cutting oil in machining operations can be a risky business.

Jed DeJong, grinding application manager for Blaser Swisslube Inc., Goshen, N.Y., said the risk of fire is one of the reasons that many manufacturers avoid cutting oil—commonly referred to as “neat oil.” But doing so might be shortsighted and hurt the bottom line. “Water-miscible cutting fluids certainly have their place, but no one can argue the fact that certain applications lend themselves better to oil,” he said.

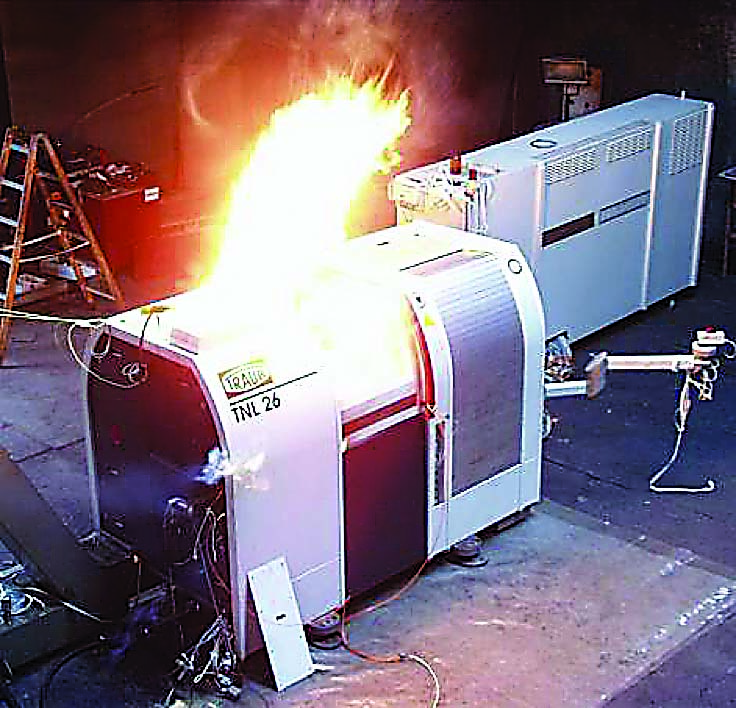

Oil fires can be prevented with well-maintained mist collectors and fire-suppression systems. Image courtesy of Blaser Swisslube.

For example, DeJong said the cutting fluids manufacturer always recommends oil for grinding carbide tools with a diamond wheel, and many machine tool builders recommend oil because it’s better for the machine than water-based fluids. “However, if you’re going to use neat oil, then you should certainly have a fire-suppression system installed.”

DeJong added that these systems are typically foam-based and utilize a canister inside the machine that is triggered by a spark or flame sensor, although powder and CO2 might also be used. Either way, manufacturers should ask their machine builder and cutting fluid supplier for application-specific recommendations. They should also invest in a mist-collection system, especially on machines where high-speed chucks and rotating cutting tools can quickly vaporize oil and make it more prone to ignite.

Users also should check the flash point of their cutting oils so they know the temperature at which an oil emits enough vapor that it is likely to ignite. Typical flash points range from 250° to 350° F (121° to 177° C) or higher. An oil with a low flash point is more flammable than one with a higher rating, and usually the higher the viscosity of the oil, the higher the flash point. All things being equal, a purer, more refined and, usually, more expensive oil will also have a higher flash point.

“If I owned a shop, I would probably use oil,” DeJong said. “Although the initial cost may be higher and [the product chosen] depends on what metals you’re cutting or grinding, oil requires far less maintenance than a water-miscible cutting fluid. It protects the investment in the machine tool and, with proper filtration and temperature control, can run upward of 10 years without disposing of any oil. You never see results even close to that with water-miscible fluids. You may get that type of longevity in a central system but not with individual machine sumps.”

Related Glossary Terms

- cutting fluid

cutting fluid

Liquid used to improve workpiece machinability, enhance tool life, flush out chips and machining debris, and cool the workpiece and tool. Three basic types are: straight oils; soluble oils, which emulsify in water; and synthetic fluids, which are water-based chemical solutions having no oil. See coolant; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flash

flash

Thin web or film of metal on a casting that occurs at die partings and around air vents and movable cores. This excess metal is due to necessary working and operating clearances in a die. Flash also is the excess material squeezed out of the cavity as a compression mold closes or as pressure is applied to the cavity.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.