A miniaturized system for spindle monitoring could have a big impact on machining costs.

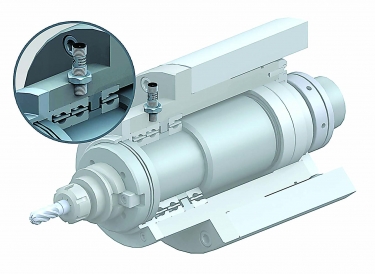

Developed by Balance Systems SRL, Pessano con Bornago, Italy, the B-Safe System contains a sensor unit with a cable, along with an electronic interface. The sensor unit attaches to a machine spindle, and the cable transmits data from the unit to the electronic interface, which is stationed in a nearby electrical cabinet.

Measuring ½" in diameter and 1¼" in length, the sensor unit’s housing is the smallest of its kind in the industry, said Francesco D’Alessandro, manager of Balance Systems’ branch in Wixom, Michigan. In addition to sensors, the unit contains a microprocessor with integrated memory.

“It’s not a simple sensor but a real microcomputer,” he said.

The small B-Safe sensor unit measures vibration and temperature for collision detection and preventive maintenance. Image courtesy of Balance Systems

Sensitive elements in the unit include a temperature sensor and a 3-axis accelerometer that detects spindle vibration and the direction of spindle movement. The sensors use a combination of 3D microelectromechanical systems and piezoelectric technology to analyze signals. The sensor unit must be firmly attached to the spindle to accurately detect vibration and temperature. For this purpose, Balance Systems provides a magnet and various mechanical adapters.

B-Safe’s electronic interface includes a bus converter that changes the signal from the sensor unit so it can be read by a PC and transmitted via the internet. The interface also houses a small battery that provides power to the sensor unit to enable spindle monitoring even when machine power is off.

One of B-Safe’s main functions is to detect any type of collision during machining—for example, a tool colliding with a workpiece or machine component. The system identifies collisions by detecting spikes of vibration and temperature that reach or surpass preset thresholds. When this occurs, B-Safe stops the machine within 1 millisecond to prevent expensive damage to both the machine tool and workpieces. B-Safe halts a machine by sending a signal to the inverter or programmable logic controller. When a collision is detected, B-Safe also provides users with spindle vibration and temperature data for the time period from four seconds before the collision to one second afterward.

“If you want to do some post-process analysis of your collision,” D’Alessandro said, “you can see exactly what was happening in your spindle during the four seconds before, which will help you to identify the reason for the collision.”

The sensor unit attaches to a machine spindle using a magnet and various mechanical adapters. Image courtesy of Balance Systems

B-Safe features a predictive maintenance function that estimates the remaining lifetime of a spindle based on the use of a machine tool. During machining, the system uses collected vibration and temperature data to determine the severity of the conditions in which the spindle operates. The system then adjusts the spindle lifetime accordingly. The results are shown using a bar that changes in length and color as time passes. Predictions of remaining spindle life help users schedule maintenance periods for times when they are least disruptive.

“Suppose you are close to your Christmas shutdown, and your spindle (has reached) 80% of its life,” D’Alessandro said. “With that information, you might decide to rebuild the spindle over the Christmas shutdown. You’ll lose the 20% of residual spindle life but with the benefit of not having to stop the machine to rebuild the spindle during working time.”

One possible downside of the system is that it does not transfer data wirelessly between its two components. While wireless sensors are commercially available, he pointed out that regulations require B-Safe components to be connected via cable because the system’s damage-minimizing collision detection capability is considered a safety feature.

“So when you install it, you have to figure out how to run the cable between the spindle and the electrical cabinet,” he said.

Potential users, however, may well decide that’s an acceptable price to pay for a safer machining process.