By Velo3D Inc.

Humankind launched the first orbital satellite in October 1957. Sixty-five years later, more than 5,000 satellites are in service, with roughly half placed into low Earth orbit over the past two years. Much but not all of this activity comes courtesy of entrepreneur Elon Musk, whose SpaceX-launched satellite internet constellation Starlink soon will account for at least half the objects circling the planet.

“We don’t think this rapid growth is an anomaly,” said Max Haot, founder and CEO of Launcher Inc., an aerospace firm in Hawthorne, California. “We think it’s the beginning of what’s to come. In fact, we believe there will be hundreds of thousands of small satellites in orbit within the next decade.”

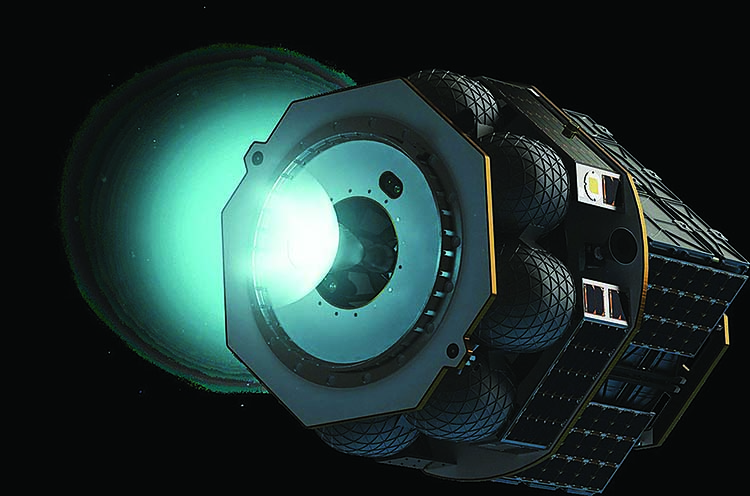

He plans to be a big part of what he refers to as a small-satellite revolution. This year, his company will leverage SpaceX’s Smallsat Rideshare Program to carry Launcher’s Orbiter satellite transfer vehicle and platform into space, where the vehicle will deploy up to 400 kg (882 lbs.) worth of CubeSats and other small satellites per mission and precisely place them into whatever orbit their owners desire. And beginning in 2024, the company will offer its own launch service, Launcher Light, which is a liquid-fueled rocket measuring 15.2 m (49.9') long and 1.1 m (3.6') in diameter that will carry 150 kg (331 lbs.) and 105 kg (231 lbs.) payloads into low Earth orbit and sun-synchronous orbit, respectively.

Orbiter is the top end of the rocket’s three-stage design, Haot explained, and was supposed to be the last part of the vehicle to be developed. But when Hawthorne-based SpaceX, which formally is known as Space Exploration Technologies Corp., announced in early 2020 that it would begin selling payload space on its Falcon 9 rocket, he and the Launcher team realized they could make their satellite deployment system compatible with it and other launch platforms. They decided to fast-track that part of the project.

“Seeing an opportunity to give our customers the best of both worlds, we brought Orbiter to the head of the line,” he said. “At the same time, we continue our work on the Launcher Light’s mechanical structures, the fairing and, perhaps most importantly, the engine, all in preparation for its first commercial flight in 2024. So it’s been a very exciting year, with 80% of the organization’s manufacturing capability focused on building our first Orbiter, which is flying in October of this year.”

The goal of all this of course is to make satellite deployment both easier and more affordable. Between the Rideshare program and the Orbiter transfer vehicle, the startup firm soon will be able to place payloads into customized orbits for a little more than $8,000 per kilogram.

“These ride shares occur every three months, but if SpaceX’s timing or trajectory does not meet our customers’ requirements, we’ll also have a premium launch service through our Launcher Light offering,” Haot said. “Either way, these services come at a price tag that’s unprecedented in the space industry.”

He and Head of Manufacturing Tim Berry point out that none of this would have been possible without additively manufactured metal components, the most challenging of which were produced on a Sapphire 3D printing system from Campbell, California-based Velo3D Inc.

“The Velo Sapphire with its ability to reliably print complex geometry made it very easy for us to pivot in the face of shifting priorities,” Berry said. “That’s a benefit of additive technology in general but especially when you’re using a highly capable print platform.”

He should know. Before joining Launcher, he worked at SpaceX for eight years and led the Falcon 9’s second-stage integration team, followed by leadership roles on the Dragon’s crew and cargo capsules before transitioning to head of additive manufacturing. Today, he oversees Launcher’s 2,230-sq.-m (24,000-sq.-ft.) factory floor and its team of machinists, welders and technicians, as well as its small fleet of metal 3D printers, chief among them the Sapphire systems.

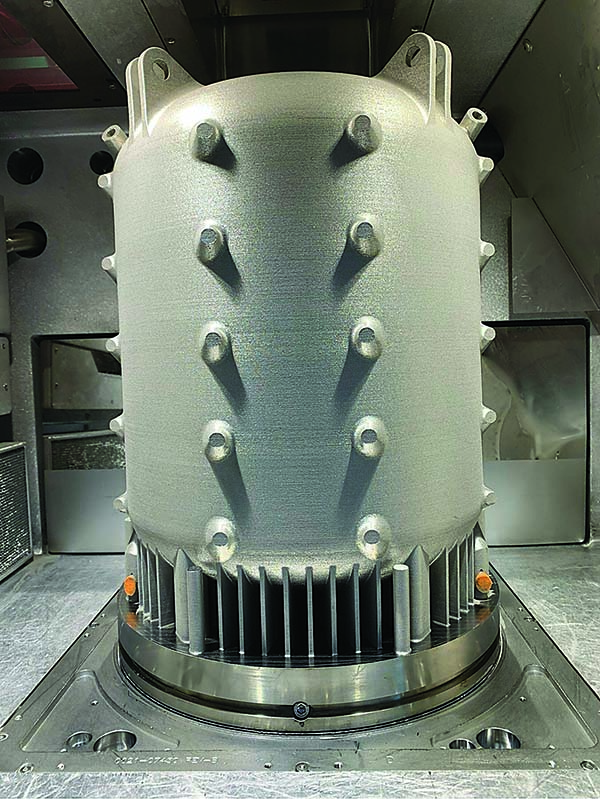

As noted earlier, Launcher began its most recent development efforts with the Orbiter rather than the rocket’s main stage that would carry it into space. And since no rocket flies without a rocket engine, the company licensed the drawing for a space-proven turbopump, then set about improving its design using additive manufacturing technology.

Unfortunately, no metal AM equipment provider could produce many of the necessary components. One notable example was the engine’s shrouded impeller, an extremely critical, complex Inconel part that spins at 30,000 rpm, must withstand more than 300 bar of outlet pressure and is filled with notoriously hard-to-print zero-degree angle surfaces.

“The team at Velo3D took the challenge,” Berry said, “and we ended up with a finished part that exceeded all of our performance objectives. That was the beginning of our relationship.”

That relationship continues to this day. Before investing in its own AM equipment and other metalworking machinery, Launcher subcontracted most of its parts to Velo3D’s network of contract manufacturers. And while those companies did a good job, Haot knew he never would reach his goal of fast, flexible and, above all, cost-competitive manufacturing unless Launcher became as vertically integrated as possible.

“As a modern space and rocket company, we have several important goals,” he said. “The first and most obvious one is for Orbiter to deliver the lowest cost in the industry for the highest propulsive capability. But to achieve that, it’s critical to have in-house design and manufacturing capabilities. Every time you buy a separation ring, propulsion system or support structure from a third party, your costs and lead time easily rise by a factor of 10. So instead of the week or so it takes us to design an engine, print and test it, we would spend maybe two or three months with an outside provider. It’s prohibitive.”

Contact Details

Related Glossary Terms

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- payload ( workload)

payload ( workload)

Maximum load that the robot can handle safely.