Overview of superabrasive grinding wheel bonds.

|

|

When it comes to superabrasive grinding applications, it’s important to choose the right wheel bond for the specific part material and geometry. Doing so will help maintain the part’s metallurgical quality and optimize the inherent capabilities of the machine tool.

There are five types of bonds available for superabrasive wheels: metal, plated, vitrified, phenolic resin and polyimide resin. Each has distinct advantages in terms of cost, physical properties and operating parameters (see Tables 1, 2 and 3).

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

Metal & Plated

The oldest bonding method, metal, is now limited to niche applications such as the grinding of automobile glass. The dense structure of the metal bond results in a wheel that is highly resistant to abrasion. When grinding glass, the abrasive glass chips expose the wheel crystals with a minimum of manual dressing.

But the metal-bond wheel grinds more slowly than wheels with other bonds. And chips that form during the grinding of hard metals and ceramic materials prevent the crystals of the metal-bond wheel from being sufficiently exposed without frequent manual dressing with aluminum-oxide sticks. This makes these wheels unsuitable for high-volume production applications.

Metal-bonded wheels also generate high heat, which can result in the cracking, chipping or burning of hard metals and ceramic materials.

Plated wheels consist of a single layer of superabrasive grains that is electroplated (typically with nickel) to a steel body. Plated wheels may have the most intricate forms and be capable of running at the fastest speeds.

And because of their single-layer structure, these wheels are generally the most economical choice for short runs of intricately shaped components. Most of the other benefits they offer relate to ease of use, as truing and conditioning are not normally necessary, and effective operation doesn’t require sophisticated equipment to maintain component size and form.

There’s a relatively wide space between a plated wheel’s crystals. As a result, approximately 40 percent of each crystal is exposed. This allows it to penetrate the workpiece to nearly its full level of exposure. While this translates into a high material-removal rate, the finish is poor when compared to other bonding methods that use the same-sized superabrasive grain.

And since plated wheels have only a single layer of superabrasive crystals, they wear out more quickly than wheels with other bonds.

Additionally, it is critical with a plated wheel that the grinding equipment be capable of attaining spindle speeds high enough to maximize wheel life and performance. For example, when grinding ferrous metal with a single plated layer of cubic boron nitride, the spindle must operate at a speed of at least 24,000 sfm (120 mps).

Coolant is usually required. Straight oil is preferable to water-soluble lubricants, because the heat resistance of nickel plating is lower than the heat generated at the grinding point. As the nickel rubs against the workpiece, the heat generated must be carried away quickly. Straight oil transfers heat more quickly and also offers better lubrication than water-soluble oils. Better heat dissipation will extend the wear lives of the crystal and plating.

‘Frit’ & Phenolic

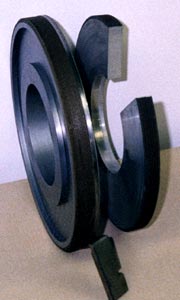

A metal-bond diamond wheel on an automatic surface grinder. The dense structure of the metal bond results in a wheel that is highly resistant to abrasion. |

|

A plated CBN wheel (left) is used for thread finishing to a tolerance of ±0.0005”. The phenolic-resin CBN wheel (right) is used to rough the thread form. |

|

A resin-bond diamond wheel grinds PCBN-tipped inserts. Resin-bonded wheels are the popular choice of cutting tool and insert manufacturers. |

|

The vitrified bond consists of a glass binder that is commonly known as “frit.” Primarily used with CBN, vitrified-bond wheels excel in applications that require unattended grinding of large lot sizes. Part finishes can be closely controlled by using truing and dressing parameters input into the part program and applied by a rotary diamond truer during the grind cycle.

Superabrasive wheels made with other bonds cannot run continuously, making vitrified CBN wheels the most economical choice for the mass production of parts such as crankshafts, camshafts or fuel-injector pins.

Another advantage is that a vitrified bond possesses sufficient porosity to allow lubricant to be added to the wheel itself. Commonly called in-bound lubricants, the technique places discrete pArticles of lubricating material in the wheel matrix during the manufacturing process.

The lubricant disperses as the structure wears, effectively reducing friction and heat in the cutting zone. These in-bound lubricants also reduce wheel loading by preventing materials from sticking to the bond surface.

However, there are performance limitations to vitrified bonds. The bonding structure makes it very difficult to hold sharp radii (under 0.010") during long production runs. Vitrified wheels also need reasonably high grinding pressure, so the same brittleness that facilitates dressing and truing during the grind cycle also causes the form to degrade rapidly. Vitrified wheels are also the most prone to damage, and may need to be replaced more frequently.

The phenolic-resin bonding method is used for general-purpose grinding wheels. It consists of a multilayer superabrasive that is held in place by a phenolic resin and various filler materials. This bonding method is popular for wheels used by cutting tool and insert fabricators, and is the most common choice for grinding parts with simple form requirements.

As with plated wheels, resin-bonded wheels are flexible. Resin-bond wheels may be used to grind dry, and their structure is weak enough for them to work effectively on surface grinders with low-speed and horsepower capabilities.

Resin-bonded wheels are relatively inexpensive (only plated wheels cost less) and easy to use. But this ease of use is tempered by the fact that they must be trued—usually with silicon carbide—and conditioned with Al2O3 dressing sticks.

Additionally, resin wheels dull quickly when exposed to high heat. And as the wheel wears, higher grinding pressures are required, increasing the rate at which the wheel dulls.

Polyimide Resin

The polyimide-resin bond is considered the most versatile of the five superabrasive wheel bonds. The bonding process can be customized to make a grinding wheel as tough, brittle or ductile as the application demands.

While similar to the phenolic bond, a polyimide resin is a stronger, higher-temperature binder that requires less volume in order to bond the superabrasive material. This allows the polyimide resin to be combined with a wide variety of other materials to make the wheel structure more heat-conductive, abrasion-resistant and easier to form.

The polyimide bond can also accommodate in-bound lubricants, resulting in longer wheel life and less workpiece damage due to friction and heat in the cutting zone. And, wheels bonded with a polyimide resin can also run at faster speeds and feeds than phenolic-based wheels, and they require fewer wheel changes during production runs.

A manufacturer of round tools recently discovered the benefits of polyimide-resin wheels. The company needed to eliminate a production bottleneck caused by the slow feed rates and frequent dressing of its phenolic-resin wheel. It considered purchasing additional machines, but first tested a polyimide wheel.

The new wheel allowed the machining speed to be increased 80 percent. Part output between retruings rose 400 percent. While the polyimide wheel cost twice as much as the phenolic-resin wheel, it yielded an overall cost savings and saved the company from having to purchase new equipment.

As this example illustrates, choosing the right superabrasive wheel bond can pay off both in cost savings and convenience.

About the Author

Ed Galen is the manager of superabrasive grinding systems for CITCO operations, Landis Gardner, a UNOVA company, Chardon, Ohio.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- burning

burning

Rotary tool that removes hard or soft materials similar to a rotary file. A bur’s teeth, or flutes, have a negative rake.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- cubic boron nitride ( CBN)2

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- ductility

ductility

Ability of a material to be bent, formed or stretched without rupturing. Measured by elongation or reduction of area in a tensile test or by other means.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- straight oil

straight oil

Cutting fluid that contains no water. Produced from mineral, vegetable, marine or petroleum oils, or combinations of these oils.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- truing

truing

Using a diamond or other dressing tool to ensure that a grinding wheel is round and concentric and will not vibrate at required speeds. Weights also are used to balance the wheel. Also performed to impart a contour to the wheel’s face. See dressing.