Dear Doc: My ID wheel goes from 3" to 2" at a constant 10,000 sfm. I seem to get chatter constantly when the diameter is around 2.5", and then I dress a bunch off and the problem goes away. What’s going on?

The Doc Replies: Chatter is my least favorite subject because there are so many different types of chatter. One possibility is that as the wheel rpm gradually increases from 12,732 rpm to 19,100 rpm [rpm = 12 × sfm ÷ (π × wheel diameter in inches)], it passes through a resonant frequency of the wheel and spindle assembly. When the wheel speed is at or near this frequency, the spindle displaces, which means it literally starts to uncontrollably bounce up and down at high amplitude.

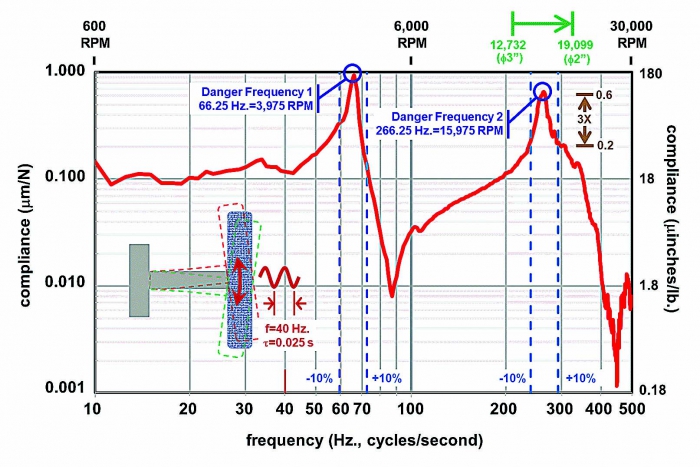

A frequency response function of the wheel and spindle assembly on a cylindrical grinder, courtesy of machine tool vibration expert Jon VanSant, shows the “danger frequencies.” Image courtesy of J. Badger

The figure shows the measured frequency response function of the wheel and spindle assembly on a cylindrical grinder. To build an FRF, intermittently push up on the spindle at a low frequency and measure how much it displaces. Then, repeat at higher frequencies and plot compliance versus frequency. (Compliance is the inverse of stiffness.)

A spindle usually doesn’t displace much, but at certain frequencies, it does so significantly. In other words, the wheel and spindle assembly is always bouncing up and down a tiny amount. But at some frequencies, the bouncing becomes huge.

How huge can this amplitude become? The figure shows a log-log plot. What looks like a small difference is actually enormous. In this case, the danger frequencies are 66.25 Hz and 266.25 Hz. If you run a wheel at or near 3,975 rpm or 15,975 rpm, the spindle starts bouncing frantically up and down, causing big scallops on the workpiece—i.e., chatter.

In your case, danger frequency No. 1 is outside your rpm range (the green arrow in the figure). But danger frequency No. 2 isn’t and occurs when the wheel is about 2.4" in diameter [diameter = 12 × sfm ÷ (π × rpm)].

What’s the solution? Your operator is getting away from the danger frequency by dressing the wheel, which increases the wheel rpm. A better approach is just to increase or decrease the wheel rpm by, say, 10 percent. It might not look like much on the log-log scale, but this modest change will reduce your compliance by a factor of 3 (the brown arrow in the figure).

Changing the wheel rpm is a quick, first thing to try that may solve the problem. If not, you’ll have to dig deeper, which involves calculating chatter frequency from the distance between chatter marks and the workpiece velocity and then trying to pinpoint the source of the chatter. The next step is to use a hammer and accelerometer to determine natural frequencies of wheel-spindle assemblies, dresser-spindle assemblies and the workpiece.

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.