Measurement data plays a key role in machine maintenance, worker safety and product quality. Sensors placed both with the machines and in the plant collect a range of useful data, including temperature fluctuations, vibration frequencies and DOC. Evaluating this data and appropriately responding and adjusting improve operations, extend machine life and increase productivity.

However, a time lag is typical between when the data is gathered and when it is evaluated. Through the development of its 5G test bed, the Fraunhofer Institute for Production Technology is out to deal with that lag.

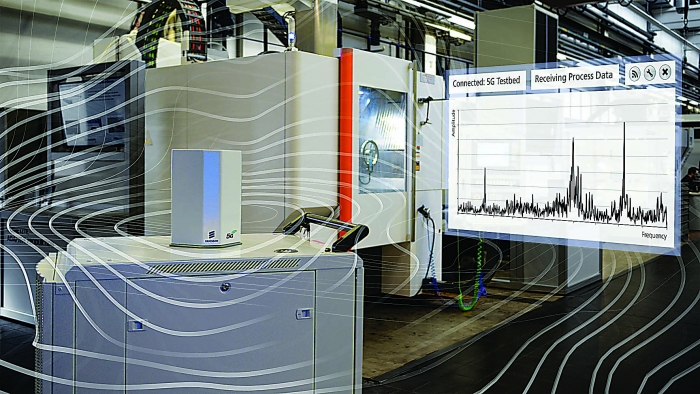

A sensor transfers the blisk’s vibration spectra at 5G speeds to a software program

that provides real-time analysis. Image courtesy of Fraunhofer IPT

To help with the transition to Industry 4.0, companies will be able to use Fraunhofer IPT’s test bed to test and further develop their products and technologies. They will be able to use wireless capabilities to transmit and evaluate measurement data in real time.

Fraunhofer IPT collaborated with Swedish technology provider Ericsson to showcase the test bed at the Hanover Fair in April. The demonstration focused on a compressor component, a blisk, used in aero-engine manufacturing. The blisk (blade-integrated disk) is an expensive component that must conform to exceptionally high safety and quality standards.

Fraunhofer IPT developed special sensors attached to the blisk. They can convey vibration data at 5G speeds to software that can instantly determine whether the vibrations are meeting the required frequencies and, if not, what adjustments are needed. The program also generates a virtual reflection of the component that can be used to address production questions.

“We hope our appearance at the fair will encourage interested companies to visit us in Aachen so they can profit from our unique test environment for 5G applications,” said Niels König, the manager for Fraunhofer IPT’s production metrology department. The institute will also exhibit at IMTS 2018.

By 2020, 5G is expected to be the standard for mobile communications. It will provide transfer rates of up to 10,000 Mbps of data and allow many devices to operate simultaneously. Looking at the next stages of development, König observed, “The greatest challenge facing mobile communications providers from now until 2020 will be to continue to reduce the size of transmission units, from laptop to smartphone to chip size, if possible. Our mission is to develop the measuring and control technology required.”

For more information about Fraunhofer Institute for Production Technology, Aachen, Germany, visit www.fraunhofer.de/en.html or call 011 49 89 1205-0.

Related Glossary Terms

- inches per tooth ( ipt)

inches per tooth ( ipt)

Linear distance traveled by the cutter during the engagement of one tooth. Although the milling cutter is a multi-edge tool, it is the capacity of each individual cutting edge that sets the limit of the tool, defined as: ipt = ipm/number of effective teeth 5 rpm or ipt = ipr/number of effective teeth. Sometimes referred to as the chip load.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.