06/13/2025

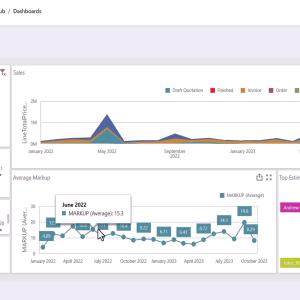

Datanomix, developer of Data-Powered Production intelligence for precision manufacturers, expanded its AI functionality across its software portfolio. AI-driven advancements include: FactoryMate, an intelligent assistant that acts like a digital floor supervisor, analyzing production reports and providing real-time analysis; G-Code Cloud + DNC, a secure and AI-enhanced platform for managing and distributing G-Code programs; TMAC AI that offers predictive quality insights by analyzing machine sensor data, including spindle load, vibration, and tool wear, detects process drift and tooling issues before they impact part quality or machine health, provides process control insights to engineers and operators alike.