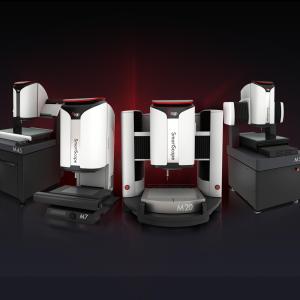

Measuring/Inspecting

Customizable touchscreen indicator brings the power of multiple indicators into one device

In a booth full of technology ranging from multi-sensor vision systems, video-based inspection and measurement systems, and even old-school optical comparators, it was a small indicator that packed a lot of punch.

That versatile indicator was the Starrett W4900 Touch Screen Indicator from The L.S. STARRETT CO., manufacturer of precision measuring tools and gages, and metrology systems.