Blogs for 11/2017

In the digitized manufacturing world being born, the product that a job-shop produces is less a piece of engineered metal and more a piece of intellectual property. So said Tom Kelly, the executive director and CEO of Detroit’s Automation Alley. That difference brings risks but also unprecedented opportunities for those who are ready.

Earlier this week we shared the conclusions of the McKinsey Report, which concluded that it may be possible for U.S. manufacturing to grow by 20 percent and add more than 2 million jobs by 2025. That was the good news. It can only happen, however, if manufacturers embrace Industry 4.0 technology. The Integr8 conference in Detroit showed how to get started.

Similar to the parts manufacturers and equipment suppliers we reach, Cutting Tool Engineering strives for continuous improvement. This endeavor includes the feature article, columns and departments, as well as our website, with our most recent efforts focused on the news section.

My Nov. 20 blog post titled "Manufacturers favor a digital workplace transformation but hold tight to their wallets" generated an insightful response from Jesse Z. Melton, owner of Harpers Ferry Toolworks.

There were a lot of deep discussions about holemaking at UNISIG’s recent open house and seminar series for magazine editors. UNISIG engineers explained different methods of deep-hole drilling, including gundrilling and BTA drilling, and provided an overview of the machines and related systems the company builds to perform these operations. Hands-on demonstrations in UNISIG’s 62,000-sq.-ft. plant augmented the classroom discussions.

A recent survey has 80 percent of manufacturers and energy companies implementing or developing a digital workplace transformation plan. Only 18 percent are allocating at least a quarter of their budget toward these efforts over the next 12 months, however—and that’s the minimum percentage needed to get started, according to Dan Chalk, director of solution engineering for NTT Data Services, Plano, Texas.

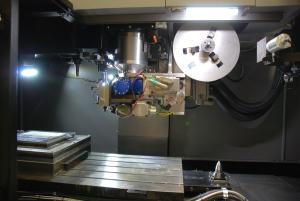

As part of the newly created 3D/Additive Manufacturing Pavilion at the FABTECH 2017 trade show held Nov. 6-9 at Chicago’s McCormick Place, Fabrisonic LLC’s exhibit showcased the company’s hybrid ultrasonic additive manufacturing (UAM) and subtractive machining capabilities.

Last week's blog post on the successors of Rosie the Riveter inspired a reader to share her own experience as an early woman in manufacturing. Lois Anderson was tasked with walking into plants in Southwestern Michigan to convince dubious managers and workers to use new methods to improve their production quality and efficiency. In the end, she helped them excel.

My October 20 post on adding capabilities to your current CNC brought a response from a reader who who shares a problem. “We have a few Kitamura MyCenter 4XiF VMCs with FANUC 16iMB controls running daily on our shop floor,” he writes, “The control hasn’t given us a single problem since they powered on for the first time. However, we haven’t been able to get the machines onto our network and we have given up trying.”

To reduce training time and improve worker safety in the high-risk environment of industrial manufacturing, Tobii Pro Insight conducts eye-tracking studies. For example, the Stockholm, Sweden-headquartered company reported that its research consultants conducted an eye-tracking study at the metal foundry of H&H Castings Inc., York, Pa., and the attention-based study revealed unique insights that will contribute to quicker onboarding of new workers, new efficiencies in its operations, new training guidelines and reductions in the risk of accidents.

Rollomatic Inc. hosted an open house Nov. 7-9 at its headquarters in Mundelein, Ill. In addition to displaying the latest Rollomatic and Strausak grinding machines, as well as a Platit tool coating machine, the event offered attendees an opportunity see a demonstration of Rollomatic’s software for Industry 4.0.