Shifting To A Rapid Rate

Shifting To A Rapid Rate

High-speed spindles excel in micromachining. Learn how advanced RPMs enhance precision and reduce cycle times.

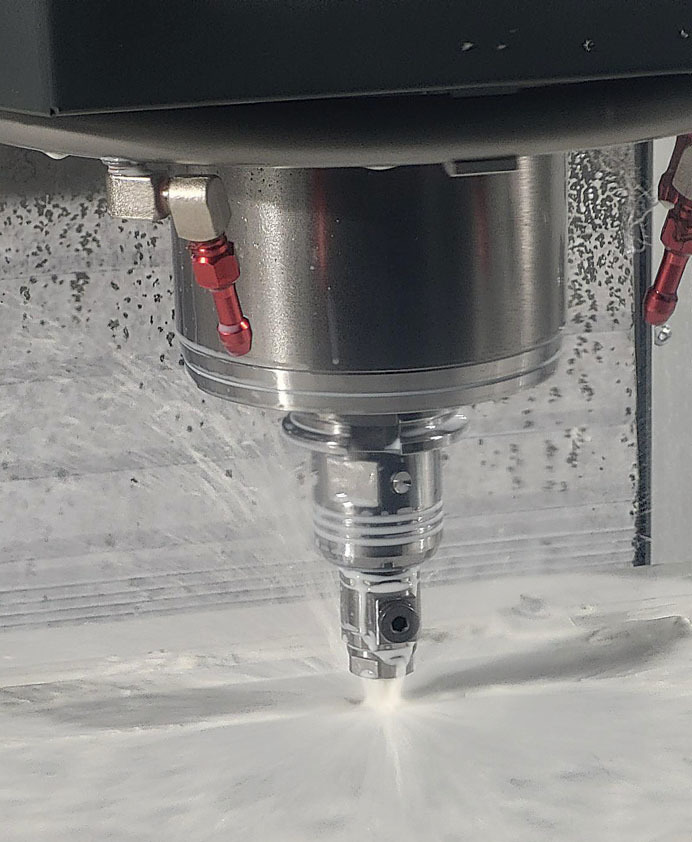

For micromachining applications, adding a high-speed, or ultra-high-speed, spindle to a machine tool provides multiple benefits, with a significant reduction in cycle times being a major one. Brian Neale, CoolSpeed product specialist for WTO Inc., noted that one customer recently was consuming about 10 hours to machine a part with thousands of small holes and reduced the cycle time to three to four hours using a Cool- Speed ultra-high-speed spindle. "Think of all the time that's going to free up."

The Charlotte, North Carolina, company supplies coolant driven spindles manufactured in Germany, by WTO Werkzeug-Einrichtungen GmbH that operate from 20,000 to 80,000 rpm.

Extending the life for microtools is another key advantage to high-speed machining, Neale said. Microtools are generally considered to be 3.175 mm (1/8") and smaller. "The smallest tool that I've actively tested with a customer is 0.003".

He explained that it can be challenging to know exactly how a microtool will function, but the "standard physics" for a larger cutting tool does not necessarily apply. "A microtool just doesn't want to run at a slower speed, so you need all the speed you can get."

When run at the proper high speed, Neale said it is possible to get two to five times faster cutting speeds and tool life on average with some customers experiencing significantly more than that.

In addition, a small tool can be effective when imparting a fine surface finish, according to Neale, especially when machining complex geometries on a variety of workpiece sizes. "Just because you're using a small tool doesn't mean it's being used on a small part."

Steve Boucher, engineering manager at GMN USA in Bristol, Connecticut, concurred that achieving a fine surface finish is a major benefit of a high-speed spindle, particularly when grinding. The company offers manual tool change spindles with speeds up to 250,000 rpm, which are primarily for grinding, as well as the UH series manual tool change spindles with a speed up to 120,000 rpm and the HCS series automatic tool change spindles for reaching a speed up to 105,000 rpm when milling. "For grinding, a lot of times the parts are roughed at a slower speed and then users just do the last surface finishing with a very high-speed grinding wheel."

Microscale grinding wheels are needed for high-speed applications, Boucher added, sometimes as small as 0.5 mm (0.02"). "Not many shops need a 250,000-rpm spindle because in that case they need to also come up with those very small grinding wheels. We have no problem coming up with the speeds, but at that point it's limited on their tooling."

He noted that the company's spindles are also suitable for applications that don't qualify as micromachining. "You can have a ½" endmill in there and it's going 40,000 rpm. That's still considered high-speed milling."

A manual tool change spindle is oftentimes used in an R&D environment or as the initial choice to determine what the spindle is capable of before getting into production, Boucher said. Then GMN can modify or redesign the spindle to provide an automatic tool change.

Added Accessories

Boucher explained that torque is frequently used at a lower speed and is inversely related to speed, so there is less torque at a higher speed because the speed makes up for the power. "With our permanent magnet motors, or synchronous motors, you have the torque throughout the spectrum."

GMN USA offers accessories for its high-speed spindles to enhance their operation, including industrial chillers, an electronically controlled lubricator, quills and spindle drives.

Because micromachining and grinding require a very stable spindle, a chiller, such as the Pfannenberg models that the company offers, provides accurate temperature regulation and effective cooling capabilities, Boucher said. Water chillers are crafted to prioritize energy efficiency, lower operational expenses and minimize environmental footprint. "Water is mixed with Glycol to keep the motor in the spindle bearing at a stable temperature to make up for any thermal expansion."

Because operators need precise, secure and controllable lubricant dosing, especially for thorough bearing lubrication during the startup and shutdown phases, GMN USA provides Prelub lubricators. "Lubrication to the spindle is very precise because it is mostly an air system with droplets of oil within," Boucher said. "It's minimal lubrication to the bearing that is required for high speed."

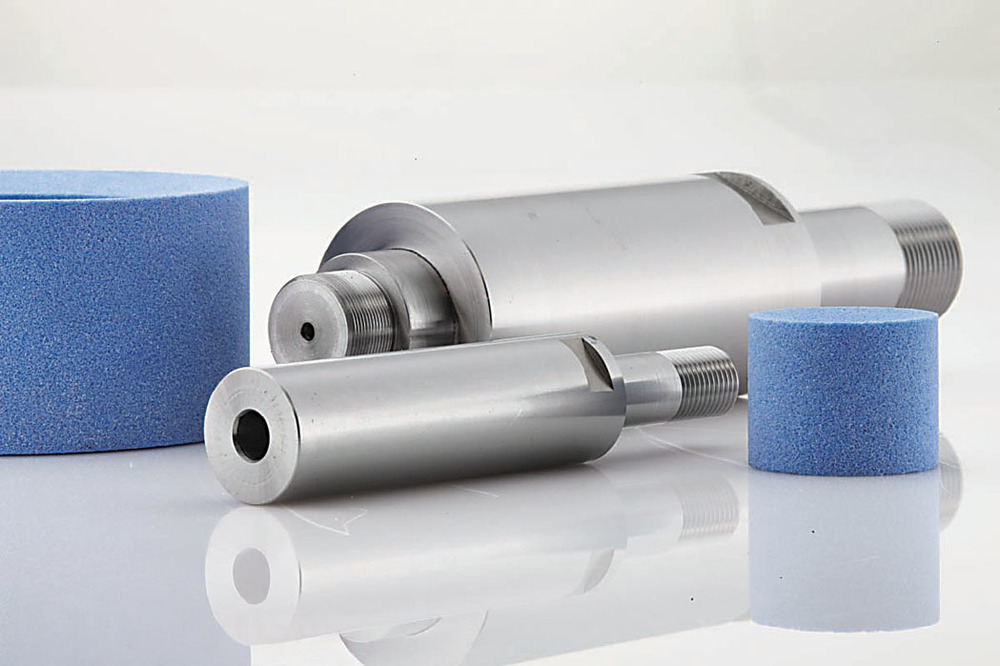

A quill allows a CNC spindle to reach into the deep, hard-to-finish recesses of a workpiece when grinding and abrasive machining, essentially a telescopic extension of a spindle. Boucher added that quills are usually made of carbide and provide minimal runout and a high level of concentricity.

Spindle drives are for high-frequency, low-induction motors, and GMN USA offers three types: open-loop drives for asynchronous motors, open-loop drives for synchronous motors and closed-loop drives with encoder feedback for automatic tool change applications.

In addition, Boucher said the company introduced the IDEA-4S (integrated data evaluation and acquisition for spindles) electronic system about two years ago for acquiring and evaluating performance, operating history and other critical data.

"You can use this tool to do preventative maintenance to make sure the spindle is in good condition with temperature, speed, vibration, and you can track this information over time and notice when it changes," he added. "You can know when a spindle is going to fail before it does, and it will prevent damage to the part being created. A lot of times the parts that are being machined are even more expensive than the spindles themselves."

Pressure and Speed

Depending on the coolant pressure, Neale said CoolSpeed mini and Flex spindles operate at 30,000 to 80,000 rpm. A pressure of 10.3 bar (150 psi) enables a speed of 30,000 rpm, and 80,000 rpm is achieved with 68.9 bar (1,000 psi). The company's new model is the CoolSpeed Max, which uses an ER11 collet and goes from 20,000 to 60,000 rpm with about two to four times the torque of the company's smaller spindles.

"A lot of customers have a standard 300-psi pump, and with those kinds of pumps you're going to get about 50,000 rpm as your max spindle speed," Neale said. "The average customer is running them around 50,000 to 60,000 rpm."

The CoolSpeed mini is a high-speed turbine-driven spindle with a dynamic runout of 4μm (0.0002"), the company reports. The cutting tool shank serves as the spindle shaft, and the spindle fits in standard toolholders for automatic tool change.

The CoolSpeed Flex was engineered for Swiss-type machines, Neale said, but WTO found that it's effective in turning centers and milling machines. It has a universal mounting shank and can be plumbed through the back or side port. "If I have external coolant only, I can plug in a coolant line right to that side port. If I have internal, or through-spindle coolant, I can plumb it directly through the back of the shank."

He noted that CoolSpeed Flex is WTO's most popular spindle by far because it has adjustable coolant jets. "If I have a lower pressure machine, let's say 300 psi, I'm going to want to run at one to two jets. It's going to create more back pressure, keeping that rpm higher."

WTO also produces spindles angled at 90° and adjustable angle spindles.

To achieve the best results, Neale recommends using the shortest tool possible to minimize deflection and vibration and one that is produced with tight tolerances. "It's better spending a little bit more on a nice tool, especially at ultra-high speeds to get the best results."

Regarding the machine tool, a CoolSpeed spindle is "plug and play" and works in almost any machine, Neale said. When considering purchasing a new machine, he added that instead of buying a machine with a 40,000-rpm main spindle, the end user can save money by acquiring a machine with a lower spindle speed and using a CoolSpeed spindle to achieve a higher speed. "That way you're not running your main spindle extremely fast. You put all that work on CoolSpeed, which is fully repairable."

Repairing Spindles

Neale added that the spindles feature a patented press-fit bearing design, enabling customers to repair the spindles themselves. "The mini and Flex series spindles are always going to run as if they were brand new." In addition, the larger Max series is self-repairable, or a spindle can be sent to WTO for repair in one or two days.

Rather than use an analog pressure gauge, which is typically installed near the coolant pump and cannot account for the pressure drop throughout the machine and gives an inaccurate estimate of the pressure flowing through a CoolSpeed unit, Neale said there are more advanced spindle monitoring options available. The new CoolSpeed MAX series spindles offer a Smart Spindle Monitoring system capable of measuring true spindle speed, temperature and vibration in real time. The mini and Flex series spindles have a Bluetooth speedometer and mobile app available to measure pressure close to the spindle and then converts it into rpm power and provides other useful parameters.

Boucher said GMN USA has a crew who are dedicated to repairing the company's high-speed and conventional spindles, as well as spindles from other manufacturers. "We bring them to the specifications we use for GMN, so we make sure the quality is there even for the non-GMN spindles."

The motors, clamping systems, sensors and other critical parts supplied by vendors for repair services meet strict GMN USA quality standards, according to the company. "Our attention to detail ensures that spindles return to our customers with 'like new' performance and reliability."