Cobot Cuts Plasma Cutting Cycle Time

Cobot Cuts Plasma Cutting Cycle Time

A collaborative robot integration slashed plasma cutting cycle times, boosting throughput and safety.

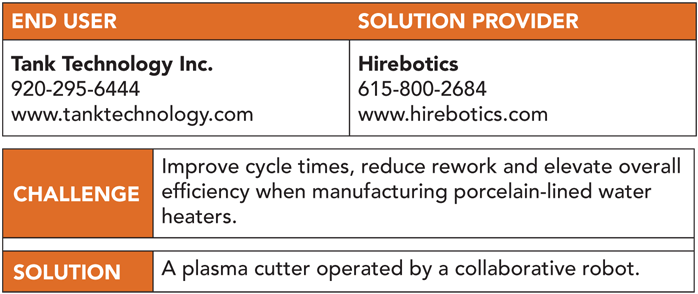

After a manufacturer has built a robust reputation for delivering high-quality, customizable products, grappling with the high volatility and inconsistency inherent in manual cutting processes can be a risky endeavor. Tank Technology Inc. faced that scenario.

With 25% of its porcelain-lined water heaters customized to meet volume, tank diameters and application requirements, plasma cutting the heads and bases by hand generated a lot of volatility and inconsistency, said Joshua Kufahl. He's production manager for the employee-owned Princeton, Wisconsin, company, which has about 50 people working two shifts at its 7,432-sq.-m (80,000-sq.-ft.) facility.

For its legacy line, Tank Technology built makeshift stencils, or jibs, for the handheld plasma cutter operator to create a line, such as for a circle, to cut along and try and get a decent fit, Kufahl explained. "Nothing was really round — ever." He used the analogy of coloring and staying within the lines. "Some people could stay in the lines, some people couldn't."

Besides the potential for error, manual cutting is a source of physical strain, he said, noting the plasma cutter tends to feel heavier than it actually is, and the plasma leads can cause issues when trying to accurately maneuver. "You're almost fighting yourself."

Curved surface and custom fittings also introduce geometric complexity inherent with building custom tanks, Kufahl added, and any solution would need to handle size and structure variability. In addition, the company's CNC machines could not accommodate the complex geometries required for their products, leading to a high rate of rework and scrap. "Speed for us at that time was the manual process."

Tank Technology also performs welding and acquired a Cobot Welder from Hirebotics in Nashville, Tennessee, to automate the process using a collaborative robot while improving welding consistency and speed, Kufahl said. "We always had that idea that we needed a plasma cutter on a robot."

Hirebotics had that idea as well and developed the Cobot Cutter, a cobot-operated plasma cutter, which Tank Technology purchased in December 2023. The lead time was short at two weeks, said Eric Pamenter, first shift ASME production lead for Tank Technology.

"With the Cobot Cutter, we're seeing perfectly sized holes, perfect location every time, repeatable locations," Pamenter said. "By hand, you can say a human is traveling at 11 to 13 inches per minute. We are traveling at anywhere from 100 to 130 inches per minute with this cobot."

The cobot enabled the company to undertake tasks previously thought unfeasible, such as beveling intricate parts with precision, Kufahl noted. Using a beveling tool requires replacing costly bits and is time consuming, requiring up to two hours to do a bevel in 12.7 mm (½;") steel plate. With the cobot, programming and the beveling process consumes about 20 minutes. "Then take a grinder and clean up the edge a little bit to get some of the oxidization off and you're good to roll."

The Cobot Cutter reduced rework due to cutting errors from 25% to nearly zero, and cutting cycle times shrank from five minutes to less than a minute on most heads, Tank Technology reports. The company realized a return on investment in about two months, Pamenter said.

The introduction of the plasma- cutting cobot not only improved the immediate production line efficiency but also set the stage for automating upstream processes, thereby enhancing future workflows, Pamenter noted. "We always say that plasma-cutting cobot is building a strong foundation for the house to sit on because it has so much repeatability and so much accuracy that it's going to well feed that upstream process that we're trying to do."

An option for the Cobot Cutter is the Beacon app, which provides end users the ability to teach the cobot with a smartphone or tablet — without programming knowledge, according to Hirebotics. The app enables real-time access for setup, monitoring and control, and allows users to enter the cutting parameters and teach the toolpath by manually guiding the cobot. Beacon will automatically populate that path after pressing the teach button on the Smart Puck.

Training was straightforward. Pamenter said Tank Technology was programming and cutting parts in the span of a week.

Kufahl agreed that the system is relatively simple to use. "If you can operate a cell phone, which most people can, you can operate this."

The integration of the Cobot Cutter at Tank Technology is an example of how automation can drive efficiency, accuracy and employee satisfaction and safety in manufacturing, Hirebotics reports.

"The fear of change is a reality in any organization," Pamenter said. The Cobot Cutter "has opened a lot of eyes and proven that these are very intuitive pieces of equipment to use. It will not take people's jobs. All it does is open up opportunities to make our lives easier and make the product better."