The quality of the sealing, braking and bearing systems must be considered when specifying a rotary table.

Job shops may believe that all CNC rotary and index tables are essentially alike. As a result, they often base their selection on price and hope they can use their machining creativity to maximize a rotary or index table.

However, to expand the capabilities of their machine tools when purchasing new ones or retrofitting existing equipment, considering the quality of a table’s sealing, braking and bearing systems and how those systems impact a shop’s current and projected applications can pay big dividends down the road. Shops are also wise to consider the effectiveness of a cable management system—which ensures a rotary table is always connected to the machine without operator intervention and extends connector life—when palletizing tables.

Courtesy of Koma Precision

“The initial quality of the rotary table makes a big difference,” said Lee Flick, national sales manager for HPI-Pioneer, “especially at job shops.” The Elk Grove Village, Ill., company supplies CNC rotary and index tables from Yukiwa Seiko Inc., Japan.

Predictably, many end users—especially shops on limited budgets—push the limits of a rotary table’s weight capacity and capability. “Some of our customers will put a car on a little table and try to turn it,” Flick quipped. But by specifying the correct rotary table for the job, shops can extend equipment life while reducing maintenance issues and continuing to machine high-quality parts.

Courtesy of HPI-Pioneer

After 2 years of operation, the inside of a Yukiwa rotary table (left) with an automatic air-purge system and a competitor’s table without a purge system.

A table axis’ lack of durability and inadequate clamping power can cause out-of-tolerance features and rough surface finishes. One solution is a dual-bearing system that supports the table on the front and rear with large bearings, according to Flick. Even with an overhanging weight load, this design prevents the table from leaning, he added.

Sealing and Purging

One of the key factors that determine the life span of a rotary table is how well it is sealed against potential contaminants, such as metalworking fluids. Flick noted the most common rotary table service is repairing electronics damage caused by coolant infiltration. “Within 20 years I believe the market will be dry cutting,” he said. “But as long as coolants are involved, sealing is extremely critical.”

Flick indicated that there are three basic sealing arrangements: sealing just the motor cavity, sealing the entire table and sealing the table and incorporating an automatic-purge system similar to check-valve pressure on an airplane. “You pressurize the cabin and if you were to get a leak, it blows outwards,” he said, adding that a rotary table with that type of seal typically lasts twice as long as one that doesn’t, whether it’s an entry-level or higher quality table.

HPI-Pioneer President Nobu Kiriyama explained that the Yukiwa air-purge system uses the 70-psi shop air that also supplies a table’s braking system and enables a table to effectively function when submerged for EDMing. For those applications, an optional nickel-plating is appropriate when the table is submerged in water-based dielectric fluid.

Of course, chips, swarf and other debris produced during cutting can abrade any seal material and provide a passageway for contaminants into a table’s inner mechanisms. Therefore, John Arnestad, tooling product manager for Koma Precision Inc., recommends against aiming a high-pressure coolant line at a seal or an area where a seal is located to reduce that risk. The East Windsor, Conn., company supplies rotary tables from Tsudakoma Corp., Japan, which have seals directly behind the faceplate. The tables also have a metal cover that shields the main seals to decrease the chance of debris abrasion.

He added that coolant infiltration primarily dilutes and washes away bearing lubricants, causing premature failure. Depending on the type of coolant, Arnestad noted a coolant mixture that is too rich, or has an improperly high ratio of coolant to water, can soften seals and cause failure.

Courtesy of CNC Indexing & Feeding Technologies

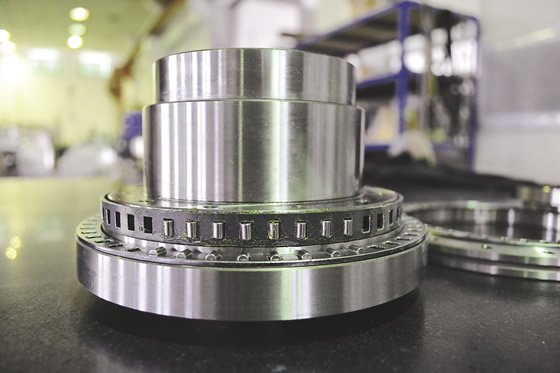

The axial and radial bearing design on a Ganro rotary table.

For high-pressure coolant applications, Rotec Tools Ltd., Millwood, N.Y., recommends a labyrinth seal on the rotary table. Rotec distributes rotary tables from Peter Lehmann AG, Switzerland. Ivo Straessle, Rotec president, noted the air-supported labyrinth seal attaches to the spindle nose of the table, extending the standard spindle seal, and creates an air cushion underneath the seal to keep coolant out. “We prefer oil-based over water-based coolants because they’re not so aggressive on the rotary tables,” Straessle said. “Many water-based coolants attack seals, cables and electrical components.”

In addition, Lehmann rotary tables have an air-purge seal on the motor housing, and the gear housing has a positive oil pressure at all times. “That makes it very difficult for debris or coolant to penetrate the seal system from the outside,” Straessle said.

To ensure longevity of the rotary table and its sealing system, pressure is reduced to the internal components of the pressurization system during rotation on most of the table models offered by L.C.M. Srl, Italy, said Mike Bickham, president of distributor ITI Tooling Co. Inc., Ramsey, N.J. Then, the pressure increases when the table reaches the preprogrammed working positions.

“The big enemy is coolant contamination,” Bickham said, noting that more flood coolant at a higher pressure is often required as machining speeds continue to increase.

Courtesy of Rotec Tools

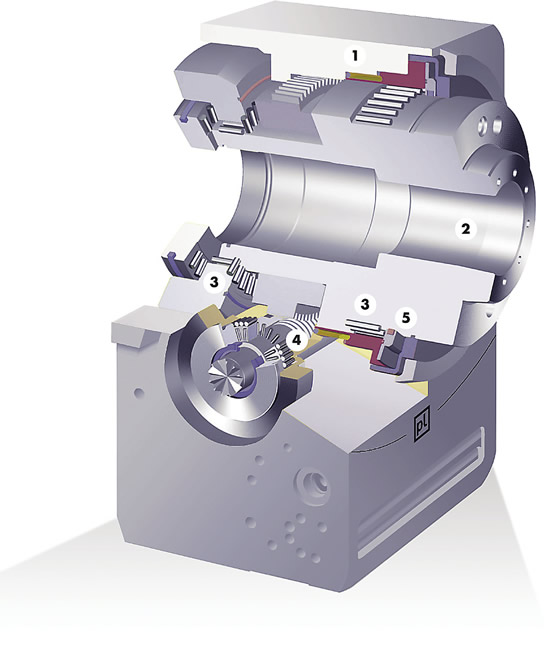

Cutaway of a Lehmann rotary table: 1) The clamping ring applies 360° equal clamping force on the rotary axis; 2) the rotary axis; 3) the preloaded radial and axial needle bearings; 4) the gear train; and 5) the standard spindle seal, which can be extended with a labyrinth seal for high-pressure coolant application.

Unless it’s an older table, coolant infiltration behind the rotary table seals isn’t an issue in 99 percent of machining applications, according to Jamie Schwarz, national sales manager for CNC Indexing & Feeding Technologies, Mason, Ohio, which offers Taiwanese-made Ganro rotary tables. A combination of oil seals, O-ring seals and silicone caulking keeps contaminants out of the tables’ inner workings, and the company offers an air-purge system as an option.

Schwarz explained that oil seals and O-ring seals are used in all areas where there are key components that require lubrication. Silicone is used around any connecting edge with internal electrical connections inside, such as motors and solenoids. Other examples include areas where one piece of sheet metal meets another and where sheet metal meets a nonmachined casting. In addition to silicone caulking, the sheet metal has a rubber/silicone adhesive seal. Areas where it’s critical to keep lubricating oil from escaping are also sealed, such as behind the faceplate and around the worm gear and worm shaft.

When coolant penetrates a rotary table, it can short out a servomotor, and fine chips can wreak wear-related havoc on the brake, worm wheel, worm shaft and other parts. “That can get expensive when you start replacing internal components that are important to the table’s accuracy and repeatability,” Schwarz said.

Braking Power

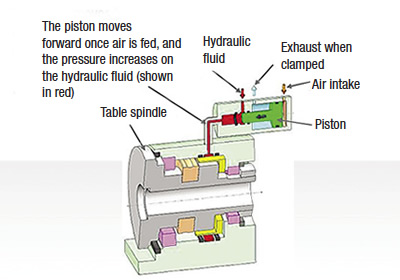

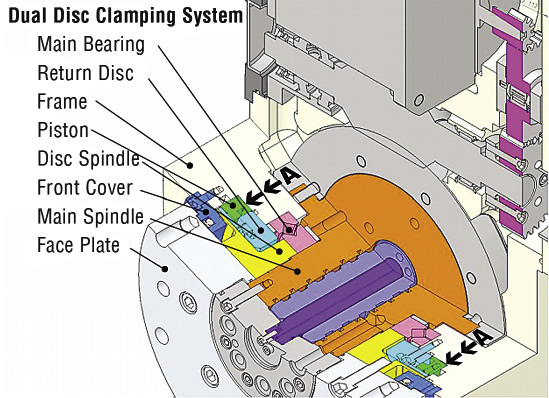

Pressure also comes into play when selecting the appropriate braking system for a rotary table. According to HPI- Pioneer’s Flick, two basic variations exist: a disc brake system and a hydraulic version that provides higher braking pressure than a disc brake. Although hydraulic systems are prevalent, he pointed out that the company offers models with the less-typical air-over-hydraulic booster inside the table’s motor cover, eliminating the need for a hydraulic pump or other external hydraulic supply. Instead, 70-psi shop air does the trick. This is because the table clamp mounted inside the air-hydro structure boosts the hydraulic pressure and achieves higher clamping power simply by providing air pressure. (See image below.)

“The higher the braking pressure, the more aggressive machining you can perform on the rotary table,” Flick said. “Hydraulic boosters are becoming more common because people want to machine harder and harder on the table.”

He added that there’s no angular pressure on any braking system when using a rotary table to cut on-center, but the type of system makes a significant difference when machining off-center because the pressure created on the cutting location increases based on its distance from the center. Hydraulic systems permit more aggressive cuts, even when machining farther out on the table.

The heavy-duty, zero-backlash braking systems on the rotary tables from ITI Tooling can use hydraulic pressure up to 870 psi, according to Bickham, but 580 psi is more typical. In addition, the tables can use an air supply together with an air-over-oil intensifier, which provides benefits because shop air is generally more readily available and is restricted to a safer pressure than a hydraulic system. Bickham added that whether it’s an air- or a hydraulic-actuated brake, the brake operates in the same manner by expanding a 360° pressurized sleeve that wraps around the table’s center axle, holding it rigidly in place.

Cost considerations can play a prominent role when selecting a rotary table’s braking system. The disc brake is the most popular type because repairs are fairly inexpensive, according to CNC Indexing’s Schwarz. The repair is usually performed on tables 10 years and older used for heavy machining, he said. “We can get the repair done within a day for a few hundred dollars.”

With the air-over-hydraulic brake system in Yukiwa’s rotary tables, the increased hydraulic pressure can achieve stronger clamping power by providing air pressure.

Arnestad indicated that Koma offers several braking system options. Called the RNE series table, the pneumatic, dual-disc system is the most economical, while offering good accuracy and a good torque drive, he noted. The mid-range RNA series table has a dual-taper clamping system that uses a pressure intensifier, where a ring of ball bearings are captured between the clamping ring and the piston.

“The piston has an angular feature on it, as well as an angled member inside the braking system so, as the piston moves forward, it displaces that ring of ball bearings and triples the clamping force,” Arnestad said. This enables taking heavier off-center cuts without the fear of the rotary faceplate turning under force.

Arnestad added that the hydraulic, dual-disc clamping system, called the RBA series table, is the company’s most robust. “That’s targeted for high-volume production,” he said, “where they need to hold very close tolerances and want to machine at the fastest rate possible.”

According to Rotec’s Straessle, Leh-mann rotary tables have the same braking system for any application, using a built-in air-over-oil intensifier. This booster coverts 90-psi shop air into more than 4,000 psi of hydraulic pressure, he added, and a clamping ring equally applies 360° clamping force to the rotary axis. “A high clamping force allows high feed rates and high workpiece accuracy.”

Bearing Down

End users can also increase machining parameters when a rotary table’s bearing configuration enhances table rigidity. For example, preloaded axial and radial needle bearings in front of the table next to the spindle nose and preloaded axial needle bearings in the rear of the spindle (all inside the gear housing) provide a high level of rigidity, Straessle explained. Preloading eliminates the undesirable “give” for the bearings in the axial and radial directions. “This design allows the customer to work with heavy workpieces and, at the same time, reduces overall vibration,” he said.

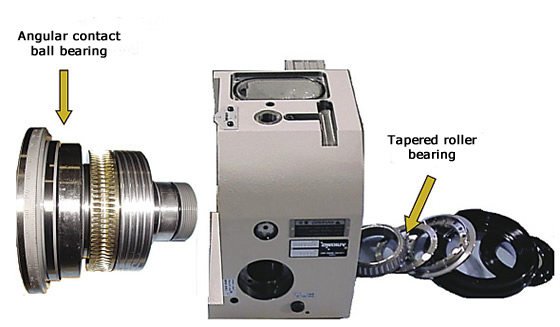

According to Arnestad, a cross-roller bearing construction provides the best rotary table support. “It gives better stiffness and less runout than, say, tapered roller bearings, which have a chance of losing their preload over time,” he said.

Courtesy of HPI-Pioneer

Yukiwa rotary tables from HPI-Pioneer have a dual-bearing system, where two sets of bearings at both ends of the body provide triple-contact support and the largest angular contact bearing is underneath the table face to enhance bearing support.

In terms of runout, HPI-Pioneer’s Kiriyama noted the bearings in Yukiwa’s rotary tables provide a 0.0001" runout and are the same grade as the ones machine tool builders use for their spindles. According to the company, the tables have a dual-bearing system, where two sets of bearings at both ends of the body provide triple-contact support, and the largest angular contact bearing is underneath the table face to maximize bearing support.

The alternative to a dual-bearing system is a single-row, center-bearing design, where, as the name implies, one row of bearings is in the center of the spindle. This design tends to enable more spindle tipping, or leaning, but HPI-Pioneer’s Flick noted it can be engineered to provide the required support.

Courtesy of Koma Precision

This cutaway of a rotary table shows the components in Tsudakoma’s hydraulic dual-disc clamping system.

HPI-Pioneer repairs and replaces worn bearings from its rotary tables, as well as from its competitors. “A good table will go 5 to 10 years before it needs work, just like a machine,” Flick said. “With a low-end table, you’re doing it annually. It’s that dramatic of a difference.”

After L.C.M. purchases ultrahigh-grade bearings, the company frequently reworks the new bearing assemblies to reduce the runout and improve the load-carrying capacity, ITI Tooling’s Bickham pointed out.

Similar to a braking system, a high-quality bearing configuration effectively supports the workpiece load and machining pressure in the axial and radial directions. This proves beneficial when machining on a rotary table that’s not adequately matched to the application. “Everyone wants to buy the least expensive table they can and push it to its limits rather than going the next size up,” said CNC Indexing’s Schwarz.

Put It on a Pallet

When high-volume manufacturers and those performing lights-out machining use rotary tables, they often palletize the tables. In this scenario, the main consideration is the cable management system, which enables a palletized table to shuttle in and out of the machine tool without disconnecting cables while keeping them clear of the machining process, according to Schwarz. It might involve running the cables through the middle of the pallet to some sort of track system or incorporating a spring-loaded arrangement that hangs from the upper sheet metal in a machine and allows cables to extend and retract.

Most end users are quite opposed to having to repeatedly plug in and unplug a rotary table, he said. As a result, the role of a cable management system, which machine tool builders and third-party installation companies provide, is critical.

Courtesy of Koma Precision

A cross-roller bearing construction in Tsudakoma rotary tables enhances support, according to the company.

Koma’s Arnestad added that a cable management system ensures a rotary table is always connected to the machine without operator intervention, which extends connector life. “If you don’t have good cable management, the connections can fail due to abrasion or having the cables flex too much,” he said. “How many times can you plug and unplug a multiple-pin connection before somebody gets a chip underneath the unit, tries to force it on and it leaks and you have problems?”

To enable a plug-and-play arrangement, ITI Tooling’s Bickham noted L.C.M. supplies its rotary tables with pallet receivers.

Going cheap across the board with rotary tables pays initial dividends, but part manufacturers that skimp on quality may miss enhancing the capabilities of their machine tools—even entry-level ones. “If you put the right options on your rotary table,” Frick said, “you can make an inexpensive machine perform as well as a midrange machine.” CTE

About the Author: Alan Richter is editor of CTE. He joined the publication in 2000. Contact him at (847) 714-0175 or [email protected].

Courtesy of ITI Tooling

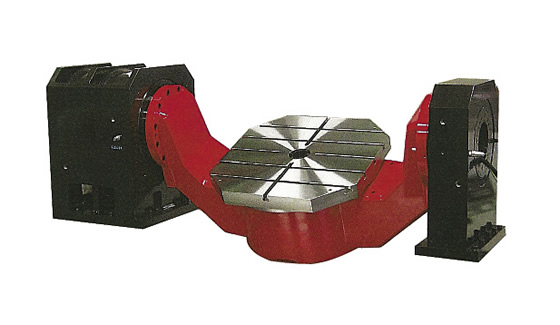

The L.C.M. Model BRS TT 600mm × 600mm, dual-axis trunnion table is powered by a high-speed, direct-drive motor.

Applications for direct-drive rotary tables

Because they don’t have gears and gear-related issues such as backlash, direct-drive rotary tables were expected to eventually replace worm gear-driven ones. For example, CTE’s April 2004 cover story stated, “Whatever the use, more direct-drive NC rotary tables will be purchased in the future, supplanting gear-driven units. These types of tables don’t have a gearbox, thereby eliminating the need to replace worm gears and belts, and are directly driven by the motor.”

That expectation didn’t quite materialize. Although they are quite accurate and rotate considerably faster than gear-driven rotary tables, reaching 250 rpm and higher compared to less than 50 rpm for a standard conventional table, direct-drive rotary tables lack the torque required for machining heavy parts and difficult-to-cut workpiece materials.

Therefore, the primary applications for direct-drive tables are high-volume ones that involve small, lightweight parts and light machining loads, according to Lee Flick at HPI-Pioneer, which offers direct-drive tables. In addition, the motor is essentially the brake. “To get the rpms, you give up torque and braking pressure,” Flick said.

HPI-Pioneer’s Nobu Kiriyama added that rotary table manufacturers have access to the same motors from motor manufacturers, which provide similar motor configurations and specifications. “Then, the various rotary table manufacturers are mostly assembling components and it’s harder to distinguish themselves,” he said. “Direct-drive technology is still evolving.”

Damaged direct-drive tables are also more costly to repair than gear-driven ones, because the components are more expensive than ones for standard servomotors, which can be rewound, said John Arnestad of Koma Precision Inc. “And if you get contamination inside a direct-drive rotary table, the motor is shot and the rotary table needs to be replaced.” Koma offers 5"- to 25"-dia. direct-drive tables.

Ganro also offers a direct-drive table, noted Jamie Schwarz of CNC Indexing & Feeding Technologies, but end users often view them as cost-prohibitive because direct-drive motors are expensive. “We quote it and then the customer says, ‘For that additional cost I think I can live with the standard table I have.’ ”

However, not all suppliers have a less-than-stellar outlook on direct-drive technology. ITI Tooling Co. Inc.’s Mike Bickham emphasized that for L.C.M.’s high-speed, torque-motor-driven tables, the company designs and manufactures many of the direct-drive motors it uses. He added that special direct-drive tables can be ordered that provide enhanced torque and, if needed, a wider range of speed. “There’s tremendous holding power for heavy-duty machining because the motor can be used as the brake,” Bickman said.

—A. Richter

Contributors

CNC Indexing & Feeding Technologies

(513) 770-4200

www.cncindexing.com

HPI-Pioneer

(866) 593-6611

www.gohpi.com

ITI Tooling Co. Inc.

(800) 88-INDEX

www.ititooling.com

Koma Precision Inc.

(800) 249-5662

www.komaprecision.com

Rotec Tools Ltd.

(914) 941-7311

www.rotectools.com

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- shop air

shop air

Pressurized air system that cools the workpiece and tool when machining dry. Also refers to central pneumatic system.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

- swarf

swarf

Metal fines and grinding wheel particles generated during grinding.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.