The controller is software in new PC-based, open-architecture machine tool systems.

With open-architecture control, real-time machine data can be displayed at the operator station or sent over a network for use throughout the enterprise.The days of single-source, proprietary "black box" controllers on machine tools may be numbered. Many software vendors, machine tool builders, and end users now envision a shop floor where machines are no longer self-contained, stand-alone units, but are totally integrated into the workings of the enterprise, providing real-time data to decision makers throughout the company. The key to making this possible is the open modular architecture controller (OMAC) that promises to eliminate the multitude of proprietary controllers now on the market and replace them with "universal" software packages that can be easily updated as new developments are introduced. "In the future, most machine tools will be PC-based, and the control systems will come in a software box," predicts Marvin Kreithen, vice president of computerized manufacturing systems, Bridgeport Machines Inc., Bridgeport, CT. "Instead of separate hardware, everything will become software."

Kreithen says that when PCs were introduced in the late 1980s, they ran at 4 mHz. Now, with a Pentium chip, they run at more than 350 mHz and cost about half as much as they used to. "There is far more intelligence embedded in the modern PC," Kreithen points out. "This can solve a lot of problems, including supplying the growing need for real-time information on what is happening at the machine tool."

Moving Toward OMAC

The move toward OMAC began in 1994 when the Big Three (Chrysler, Ford, and General Motors) banded together to develop a common set of application programming interfaces (API) to enable automotive manufacturers to customize the set of libraries used in their programs. Interest in the open modular architecture concept is now so widespread that at its meeting in Orlando, FL, last February, the OMAC Users Group attracted representatives from the automotive, aerospace, chemical, food, and consumer-products industries, as well as CNC equipment manufacturers and software vendors.

In addition to the Big Three, other large manufacturers actively pursuing OMAC technology for their shop floor include Boeing, Caterpillar, Cummins Engine, Deere, and Pratt & Whitney. Machine tool builders that have jumped on the OMAC bandwagon include Bridgeport Machines Inc., Cincinnati Milacron Inc., Ingersoll Milling Machine Co., Makino Inc., and Okuma America Corp.

The Dedham, MA-based OMAC Users Group claims that the unique benefits of an open architecture include reduced initial investments, low life-cycle costs, maximized machine uptime, easy maintenance of machines and controllers, easy integration of commercial and user proprietary technologies, and the ready ability to reconfigure controllers to support new processes.

According to the users group, because of the need to support a wide range of applications and the continual pressure to be more cost competitive, manufacturers are migrating toward controllers that provide agility and flexibility. In the future, it will no longer be necessary to replace existing controllers with newer and better models when only a few new functions need to be added. Jim Fall, vice president of marketing, Manufacturing Data Systems Inc. (MDSI), Ann Arbor, MI, says there are three paradigm shifts taking place in the CNC market today:

What Is Open?

As with most developing technologies, there are numerous opinions and definitions of what the word "open" means. The OMAC Users Group defines open as "allowing the integration of off-the-shelf hardware and software components into a controlled infrastructure that supports a de facto standard environment." Fall says that allows various control and peripheral-equipment suppliers to claim their products are open. According to that rather broad definition, many of them are.

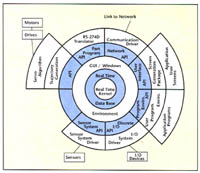

The open modular architecture controller (OMAC) concept.

(Click for a larger image)To help clarify matters, the users group acknowledges three levels of openness. The first level employs off-the-shelf PC hardware and a Windows’ operating system. The second level requires common application programming interfaces to enable manufacturers to customize their control system environment. The third level of openness removes all proprietary hardware elements (i.e., special PCs, backplanes, discrete logic control cards, and motion cards modified to run in a specific CNC machine) from the control system. The OMAC Users Group claims a controller at this level is a "software-based controller with generic processors running software modules."

In Fall's view, this is a good starting point, but it doesn't go far enough. "The ultimate goal of an open-architecture machine," he says, "ought to be achieving open access to data. But for machine control systems to reach their full potential as manufacturing data centers, they must adhere to an even higher standard of openness than that outlined by OMAC." MDSI started working on a software-only approach to machine tool control back in 1993 and recently began offering its package to industry. Fall claims that the facilities for collecting data from the machine tool and making it available to a higher level in the manufacturing process must be intrinsic to the control system. A shop shouldn't have to rely on another PC, an operator, and manual input to collect and distribute data. Data entry on the factory floor is just as time consuming, unproductive, and prone to error as it is in the office environment.

Many software suppliers are already aware of the need for greater integration of data in the manufacturing process, even though they are far from embracing the total concept of open architecture. One example is Engineering Geometry Systems, Salt Lake City, UT, which produces a variety of software packages for milling and turning applications.

"There's a great need for improving communications with the manufacturing function," says Glenn McMinn, president. "Right now, there's usually only one group in a company handling part design, but there could be two, three, or more separate groups responsible for manufacturing. When you create a design, lots of manufacturing details simply are not there. In our products, we take the design and embed the manufacturing details in the software. It eliminates many errors and can save a lot of time and money."

McMinn calls the concept "connectivity," and although it is not true open architecture, it could represent a first small step along the way.

Market Potential

According to the latest data, there are more than 2.5 million CNC machine tools in use worldwide. Of these, 95% are proprietary closed systems that can't communicate with any other system. In addition, some 60% of the CNCs in the world are more than nine years old and need to be replaced. In addition to eliminating the constraints of proprietary systems that only OEMs can service and upgrade, open-architecture software vendors are addressing current trends, such as high-speed machining and the need for greater reliability. Many industry observers see open architecture, with its easy upgrades and modifications, as a means of postponing equipment obsolescence.

For maximum choice and flexibility, Fall says you must use an unbundled software-only product, where everything required to control the CNC machine tool is in software. This provides a choice in hardware, software, data access, and implementation. Moreover, the CNC will continue to improve throughout the life of the machine tool via software upgrades, protecting the user's original investment. Equipment and software obsolescence is very much on the mind of Shane Estes, owner of The Cutting Edge, a small machine shop in Mt. Vernon, MO. He's aware of the concept of open-architecture control and is watching developments with interest.

"I'm looking for a complete shop control system that I can modify to fit my needs," says Estes. "I want something that's able to fit into a CAM package that I can also import to the quoting side of the business. I want to be able to draw the part, simulate the machining process, and come up with a firm quote. We are moving to open architecture. I like the idea where the control is a PC and updates for it come on a floppy disk."

Like most shop owners, Estes fears investing in equipment that will soon become obsolete. "The last thing I want is to be stuck with a system that becomes outdated in two years," he adds. "That's what happens now. The equipment makers come out with new and improved controls and machines all the time. To me, a proprietary control means the competition can easily get a jump on you with an improved model."

It Won't Happen Overnight

Open-architecture controls are coming to manufacturing, but not right away. That's the opinion of Sal Spada, a senior analyst at Automation Research Corp. (ARC), a Dedham, MA-based company that tracks industrial automation trends.

"Right now, open architecture is ahead of its time," says Spada, "but eventually it will be adopted by all of industry. Many vendors are already developing more tightly packaged controls, which are moving into the drives in a compact package. They aren't open, but at least they are a step in that direction. The wide availability and low cost of PCs is going to help speed up the process, particularly when people begin understanding what open controls can do for them."

Open architecture will have a major impact on software developers, predicts Spada, particularly those who supply CAD/CAM systems. "They should be looking seriously at open architecture right now," he warns. "It's important to them that they have products that will go in a desktop." Spada believes one of the forces that will drive open architecture into the manufacturing marketplace is the growing shortage of skilled labor. "There's a greater interest today in how people interface with the equipment they use," claims Spada. "Even before the concept of open architecture came along, the major control vendors were moving into tighter packages. There's a realization now that we have to take the load off the machine operator."

The desire for simplicity isn't limited to unskilled operators. Dave Huard, a skilled CNC programmer at KLK Inc., a 30-person job shop in Phoenix, says that less complex software packages are at the top of his wish list.

"We never use many features in the existing programs, but we can't turn them off," explains Huard. "I want programs where I can eliminate unnecessary features and remove redundancies. I'd love a program where I can turn a feature off, but then turn it back on if I need it later." According to Huard, there's a great disparity between the tool paths most post-processors use and what he uses. "The codes are too long," he claims. "If you need to make a change, it's a real chore to locate the right place in the tool path. As part complexity increases, the software become very cumbersome and editing becomes a real burden. It's important that the people who design software focus on simplicity."

Windows NT Is Important

Industry observers believe Windows NT is going to play a role in the move to open-architecture controls. "With Windows NT, you can take a variety of component software solutions and just plug them in," explains ARC's Spada. "That includes tool monitoring, wear packages, and many others. Now, these are all specific to one manufacturer's machine and have no interchangeability." Current manufacturers of hardware and control systems are a major cause of the delay facing open architecture. "It's going to take a while for them to give up their proprietary hardware," Spada predicts. "Companies that now make the drives, motors, and controls used on the whole range of current equipment don't want to throw that business away. But many of them already know that in time, they probably won't have any choice."

New lines of work may open up for them. According to Spada, the acceptance of open architecture by industry in general will produce a new form of service providerÑthe integratorÑto supply the service and support now provided by individual manufacturers. "It's a function that somebody will have to take over," concludes Spada.

About the Author

Robert Eade is a Waterbury, CT-based business writer who has been reporting on trends and issues in metalworking and manufacturing for 35 years

Related Glossary Terms

- arbor

arbor

Shaft used for rotary support in machining applications. In grinding, the spindle for mounting the wheel; in milling and other cutting operations, the shaft for mounting the cutter.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.