Time, money and control. Those are three critical elements for any successful manufacturer of precision metal parts. Bringing the heat treatment process in-house by purchasing an appropriately sized furnace or oven benefits part manufacturers in all three.

Which one is most important depends on whom you ask. “I would say that a lot of our customers are starting from the perspective of managing the turnaround time to heat-treat their parts first and foremost,” said Robert Hauser, sales manager at Lucifer Furnaces Inc., Warrington, Pennsylvania. “For larger operations, managing cost becomes an equally important issue.”

He added that typical turnaround time can be as long as two to three weeks when sending parts to a commercial heat-treat company. In contrast, a job shop could heat-treat a small part in as little as 15 minutes in-house if it has the right equipment.

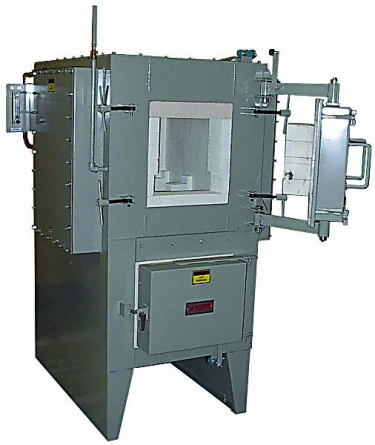

The KMTG-27 fire box furnace from Knights is equipped with a guillotine-style door. Image courtesy of Knights

David Harrell, account manager at Knights Corp., Bentonville, Arkansas, which offers Dragon Fire heat-treat furnaces, indicated time and cost as the two biggest benefits for machine shops that perform heat treating in-house. “The third parties, costwise, are going to charge minimums,” he said. “If you just have one or two pieces, they are going to charge an extra $150 to $200 as a minimum.”

Gaining more control of the heat-treat process tops the list for buyers of Grieve Corp.’s furnaces and ovens, according to Yuriy Pospelov, national sales manager at the Round Lake, Illinois, company. “They have more control as they bring heat treating in-house, and they can do it whenever they want,” he said.

Test Run

One option to determine if a manufacturer’s equipment will achieve results similar to those of a commercial heat treater is to have the manufacturer heat-treat a prospect’s part.

“Prospects want to see what happens when they put their parts in an oven or furnace for several hours,” said Frank Calabrese, vice president of sales at Grieve. “They send it here, and we run the tests for them.”

Grieve doesn’t analyze the results of the tests but leaves it to the customer to decide if a part has the proper properties, such as hardness and color, after heat treatment.

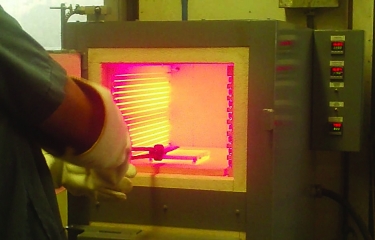

A worker heat-treats a part in a furnace from Lucifer Furnaces (top). Lucifer’s Model HS82GT-K18 dual-chamber, space-saving furnace (above is for hardening and drawing HSS and ceramics. Images courtesy of Lucifer Furnaces

Harrell pointed out that Knights primarily conducts tests when someone isn’t certain about a specific material or process guidelines are not available. “If it is a standard tool steel, it is a very straightforward process, very much like following a recipe to bake a cake. People see the process’s simplicity, and that’s the reason we don’t do more test parts.”

Hauser concurred that most prospective customers already have adequate knowledge about heat treating and are looking for an equipment manufacturer to help them select the right unit for an application. “Not to oversimplify it, but heat treating is basically time and temperature based on part size and the type of material.”

One important reason for testing parts is when someone is considering purchasing a piece of equipment with a protective atmosphere and wants to get a better picture of what that atmosphere yields on the final result.

Such a chamber would accommodate an inert atmosphere, typically using nitrogen or argon, rather than a regular air atmosphere. To effectively contain an inert gas and keep oxygen from reaching the parts so they don’t oxidize and discolor, the heat-treat unit must have a gas-tight construction, Calabrese explained. This construction includes seams that are welded continuously and a special inert gas fitting.

“It is made to be gas-tight so the atmosphere doesn’t leak out and air doesn’t leak in,” he said.

Another way to minimize oxidation while managing equipment costs is to wrap parts in high-grade stainless steel foil, Hauser noted. “They can prevent the scale and oxidation without investing in inert atmosphere equipment, which is considerably more expensive than an air atmosphere chamber.”

System Sizing

Sources agreed that most machined metal parts must be heat-treated or stress-relieved in some manner. “It could be both, or it could be one or the other,” Calabrese said, adding that stress relieving essentially involves annealing or tempering a part, such as a spring, to make it stronger, less brittle and more flexible while slightly reducing its hardness.

When considering bringing the heat-treat process in-house, most people also concurred that companies shouldn’t try to purchase a furnace or an oven to accommodate all the part sizes and materials they need to heat-treat. Instead, selecting a piece of equipment suitable for about 80% to 90% of the parts produced is the most economical approach.

“Oftentimes what happens is when someone tries to accommodate every part size or load weight, they oversize the equipment, and it gets too expensive to bring that equipment in-house,” Hauser said.

The No. 934 from Grieve is an 850° F cabinet oven that has 6" insulated walls, an aluminized steel exterior and a stainless steel interior. Image courtesy of Grieve

When a shop properly sizes heat-treat equipment, it should see a return on investment within six months to a year even if only heat treating once or twice a week, according to Harrell. “It doesn’t have to be high volume for these to very easily justify themselves.”

At Lucifer Furnaces, prices start at around $2,000 for a small benchtop box furnace, for example, and range to $160,000 or more for a large unit, Hauser noted.

Typically, when a company manufactures metal aerospace components, it must meet the AMS20750E specification, which covers pyrometric requirements for thermal processing equipment used for heat treatment. “In order to deliver on that spec, it takes some customization of our equipment,” Hauser said.

That customization includes modifying the high-temperature chamber so there are different zones of heat inside it to better control temperature distribution throughout and silicon-controlled rectifier power supplies instead of magnetic contactors to provide a steadier state of power to the heating elements. And in recirculating ovens, Lucifer Furnaces usually supplies a wire-on-rod element design to expose more of the elements in the airflow and seals the front of the oven chamber, Hauser said. “In addition, there is a whole list of specific instrumentation that’s required to meet the AMS specification.”

A gas-fired system costs more initially than an electrically powered one, Calabrese noted, but gas is cheaper than electricity in some areas, and a gas unit offers faster recovery and heats up quicker. “A big electric model would take, say, two hours to heat up; a gas model would be 1½ hours.”

For more information about heat treatment equipment from Lucifer Furnaces Inc., view a video presentation at : cteplus.delivr.com/23zp9

Of course, if a shop doesn’t have a gas line running into its facility, it purchases an electric model. Lucifer Furnaces is one builder of heat treatment equipment that focuses exclusively on electric-powered furnaces and ovens, Hauser said.

As a shop’s production capacity increases, one or more small furnaces can be added. “From multiple perspectives, including cost, we can do several small furnaces for what they’d be looking at for a large furnace,” Harrell said.

Torch Timeout

Some part manufacturers that are already heat treating in-house opt to purchase their first oven or furnace. That’s because they are using a propane or acetylene torch for the task and want to heat-treat in a safer and more consistent, precise manner.

“Heat treating with a torch is very common,” Harrell said. “Besides our customers who are coming from commercial heat treaters, that is a big piece of where our customers are coming from.”

However, for many toolrooms and job shops, a torch is a low-cost option when time is of the essence. “If push comes to shove and they need something heat-treated fast, they will pull out a torch and heat-treat it as opposed to sending it to their commercial heat treater and waiting weeks,” Hauser said.

Sales of heat treatment equipment to part manufacturers remain steady and a market with significant growth potential. Calabrese estimates that only 25% to 30% of those types of companies have heat treatment equipment in-house.

As more metal parts are 3D-printed, the market is expected to expand. That’s because after a part is printed layer by layer, it must be heated to unite those layers into a coherent mass, Harrell noted. “It is not a full-on heat-treat application. It is more of a sintering application.”

Lucifer Furnaces is also noticing more interest from additive manufacturers, Hauser said. “We have seen an increase in requests from customers who make metal parts through additive manufacturing and are looking for the last piece of the puzzle, which is to heat-treat their parts after they are made.”

Regardless of how a metal part is produced, heat treatment routinely plays a role. “I have not come across an industry that does not in some fashion either need to utilize the service of a heat treater or bring it in-house,” Hauser said.

Contact Details

Contact Details

Contact Details

Related Glossary Terms

- annealing

annealing

Softening a metal by heating it to and holding it at a controlled temperature, then cooling it at a controlled rate. Also performed to produce simultaneously desired changes in other properties or in the microstructure. The purposes of such changes include improvement of machinability, facilitation of cold work, improvement of mechanical or electrical properties and increase in stability of dimensions. Types of annealing include blue, black, box, bright, full, intermediate, isothermal, quench and recrystallization.

- ceramics

ceramics

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

- hardening

hardening

Process of increasing the surface hardness of a part. It is accomplished by heating a piece of steel to a temperature within or above its critical range and then cooling (or quenching) it rapidly. In any heat-treatment operation, the rate of heating is important. Heat flows from the exterior to the interior of steel at a definite rate. If the steel is heated too quickly, the outside becomes hotter than the inside and the desired uniform structure cannot be obtained. If a piece is irregular in shape, a slow heating rate is essential to prevent warping and cracking. The heavier the section, the longer the heating time must be to achieve uniform results. Even after the correct temperature has been reached, the piece should be held at the temperature for a sufficient period of time to permit its thickest section to attain a uniform temperature. See workhardening.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- recovery

recovery

Reduction or removal of workhardening effects, without motion of large-angle grain boundaries.

- sintering

sintering

Bonding of adjacent surfaces in a mass of particles by molecular or atomic attraction on heating at high temperatures below the melting temperature of any constituent in the material. Sintering strengthens and increases the density of a powder mass and recrystallizes powder metals.

- stress relieving

stress relieving

Annealing designed to relieve internal stresses caused by machining, welding, casting, cold working, quenching or normalizing.

- tempering

tempering

1. In heat-treatment, reheating hardened steel or hardened cast iron to a given temperature below the eutectoid temperature to decrease hardness and increase toughness. The process also is sometimes applied to normalized steel. 2. In nonferrous alloys and in some ferrous alloys (steels that cannot be hardened by heat-treatment), the hardness and strength produced by mechanical or thermal treatment, or both, and characterized by a certain structure, mechanical properties or reduction in area during cold working.

Contributors

Grieve Corp.

847-546-8225

www.grievecorp.com

Knights Corp.

800-775-1730

www.knightsfurnace.com

Lucifer Furnaces Inc.

800-378-0095

www.luciferfurnaces.com