Benefits of post-coating treatment

Benefits of post-coating treatment

Coatings for metalcutting tools have made tremendous advances since their introduction more than 40 years ago. As coatings have improved, our understanding of their behavior in a variety of cutting operations has increased, and this has led to further developments to enhance performance. A technology that has made big strides in the past few years is post-coating treatment.

Coatings for metalcutting tools have made tremendous advances since their introduction more than 40 years ago. As coatings have improved, our understanding of their behavior in a variety of cutting operations has increased, and this has led to further developments to enhance performance.

A technology that has made big strides in the past few years is post-coating treatment. As thicker coatings were developed and Al2O3coatings came into the industry, these treatments began as efforts to smooth the coating surface of CVD coatings. People observed that a smooth coating surface enhanced tool life by reducing both friction and the tendency of workpiece material to stick to the surface, which causes built-up edge. This could be called the first generation of post-coating treatment.

The surface-smoothing process is a light grit-blasting operation that removes the roughness caused by uneven coating-grain growth. Only a tiny amount of coating is removed. As these blasting processes have become more controlled, it has become possible to accurately remove a very thin layer. An example is removal of the "flash" TiN coating layer on the rake surface of an indexable insert. The advantage of the process is that it provides a smooth top surface, leaving a gold TiN layer on the flank for easy wear detection. This process could be called the second generation of post-coating treatment.

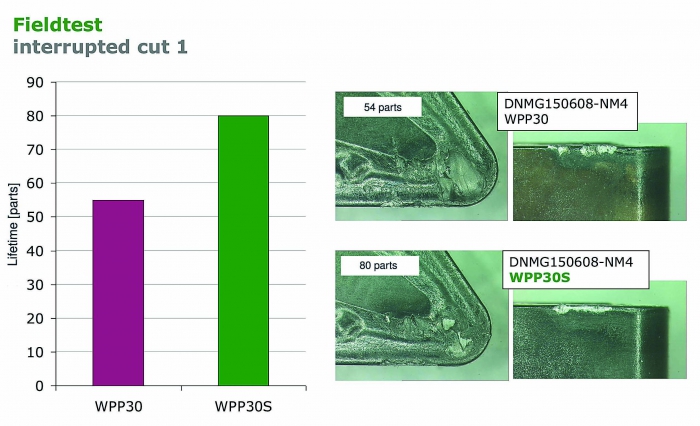

Wear on a coated insert after interrupted cutting of 54 parts (top), and wear on the same type of coated insert, but with a post-coating treatment, after interrupted cutting of 80 parts. Image courtesy of Walter USA.

Sometimes during coating, particularly during CVD processes, the coating layers can experience tensile stress. This state is caused by differences in the thermal expansion coefficients of carbide substrates and hard coating layers. A tensile-stress state can cause flaws in the coating to grow into cracks. It also tends to cause those cracks to further expand until they result in failure of the cutting edge. Most often, these cracks are generated from the stresses of the cutting operation, especially interrupted cuts.

Because coatings are ceramic materials, they are inherently weak at resisting tensile stresses but incredibly strong at resisting compressive stresses. Cracks and other flaws are unable to grow in a compressive-stress state. As second-generation treatments have been improved and controlled, it has became apparent that blasting has had the further beneficial effect of reducing the tensile stresses in CVD coatings.

Moreover, the continued development and control of many parameters in post-coating treatments has made it possible to replace tensile stresses with compressive stresses. This has led to significant improvements in the failure resistance of the cutting edge due to chipping, especially in interrupted cutting.

Because cracks are generated two ways in milling, the biggest benefits are for milling inserts. One way is from the impact that occurs every time the cutting edge enters the cut. The other way is from thermal cycling when the cutting edge heats up quickly during cutting and then cools as it exits the cut, creating thermal cracks. By having compressive stresses in the coating, the impacts and thermal cycling have to overcome the compression and then grow tensile stresses to the point at which cutting edge failure can begin.

By having compressive stresses, it takes far more cutting time and stresses to generate cracks big enough to damage the cutting edge. The increase in cutting edge life is often 30 percent or more, especially in applications involving heavy impacts and high speeds.

The figure shows a heavily interrupted camshaft turning operation with a 48 percent increase in tool life by resisting chipping of the cutting edge. These results are from the latest generation of post-coating treatments. These treatments create compressive stresses through the entire coating structure and even extend into the substrate, significantly increasing chipping resistance.

See also "Understanding coatings and how they lower machining costs."