AIO laser marker

AIO laser marker

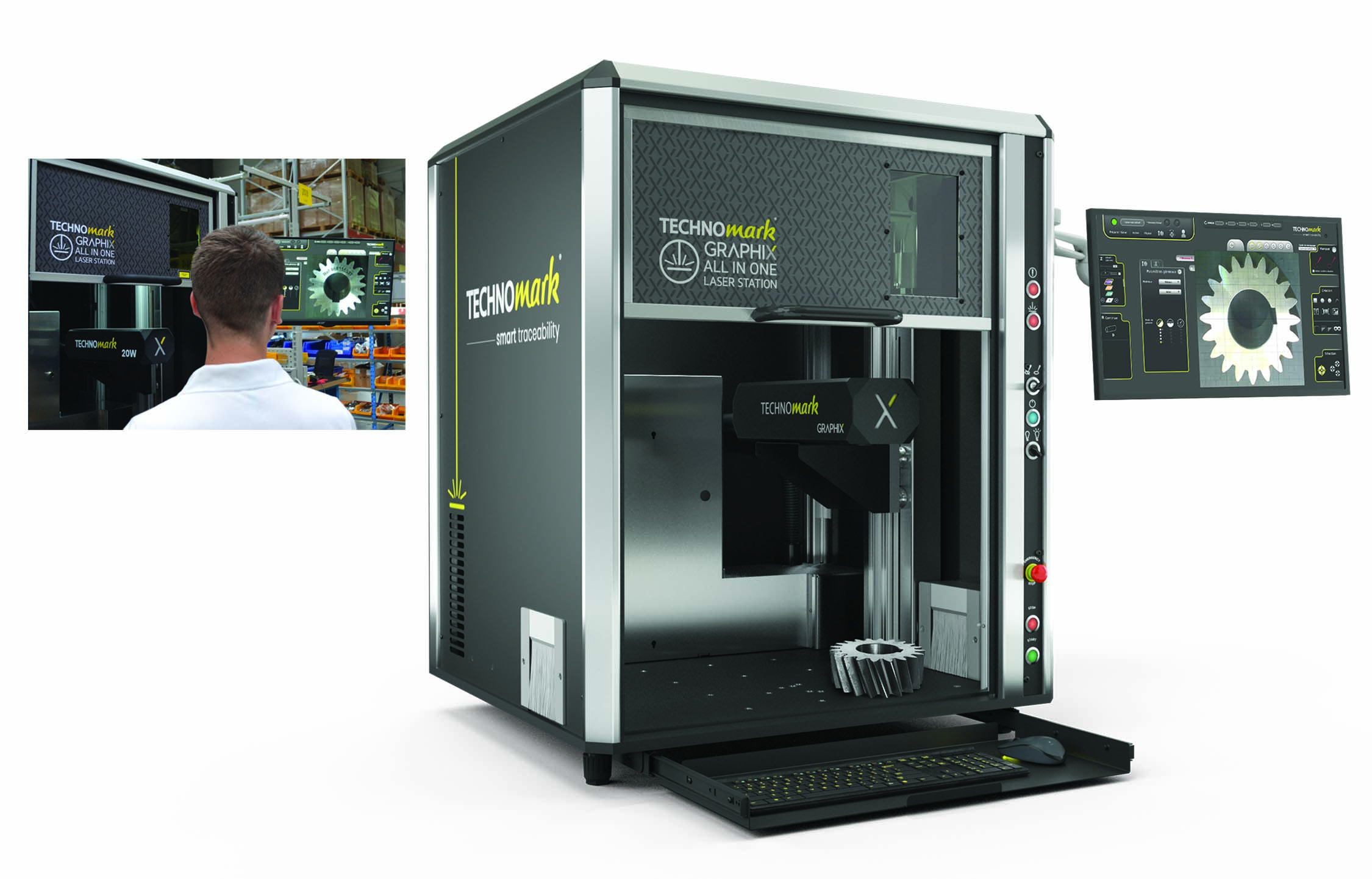

Technomark's Graphix laser workstation holds all in a single cabinet creating a small footprint.

If you're in the market for a laser marking system, why not buy one that packages all its essentials in a single compact box?

That's the thinking behind the design of the Graphix laser marking station from Technomark, a manufacturer of marking systems headquartered in La Talaudière, France. An update of an older model, Graphix is billed as an all-in-one system. In this case, that means a single boxy cabinet that contains the laser marking head, motorized Z-axis, control unit and power source, as well as space for parts to be marked.

Technomark touts the system's small footprint, which is said to allow easy installation in workshop settings.

"Usually on the market you will find a laser workstation that has only a Z-axis column with the marking head," said Mustapha Boulkouane, the company's export sales manager. The other components of these systems are housed in a big unit outside the workstation cabinet, he said, "so you will need more space to use these marking systems."

Featuring fiber laser technology that marks parts with a fine, high-intensity beam, Graphix can be equipped with three different power sources — 20W, 30W and 50W — to meet various user needs. Making the laser power adjustable offers users the ability to increase power if, for example, they want deeper or faster marking, Boulkouane noted.

With operator safety in mind, Graphix workstations are equipped with Class 1 lasers. This designation "means that the marking is totally safe — no radiation for the eye or (the rest of) the body," Boulkouane said. "Everything stays inside the cabinet."

The Graphix all-in-one laser marking station is designed to simplify installation and use. Images courtesy of Technomark

Another safety feature is the emergency stop for the workstation's two-position power door. Thanks to this feature, Boulkouane said, "the operator is guaranteed that marking will be very safe because when you open the door, the marking stops."

Graphix offers high-speed, noncontact marking of parts up to 400 mm high. Tall or long parts can be loaded through a side opening.

The system's rotating axis allows marking on curved surfaces. In addition, Graphix can automate multi-level marking of parts. Boulkouane pointed out that this process normally requires a good deal of operator involvement. "First you have to mark on one level, then move manually to the next level, perform the marking," and so on, he said. "But thanks to our software, it can be done in one shot with programming."

Curved and multilevel marking are made easier by the marking head's onboard camera. Working with the system's Smart View function, the camera lets users see and adjust the positioning of a mark on the Graphix screen. And once the mark is properly positioned, they can watch the marking process live.

The system can mark parts made of a number of different materials, but Boulkouane said it's typically used for steel, brass, copper, aluminum and titanium components. It can also be used to mark some plastics, he said, but he added that "the fiber laser is not the best one to mark on plastics."

On the front of the unit is a control panel that offers settings aimed at making marking easy even for novice users. A material database eliminates the need for complicated preliminaries to get Graphix ready for a particular application. All a user needs to do is select the part material and the desired marking result.

According to Boulkouane, Graphix "answers many requests" of manufacturers in the aeronautical and automotive industries. Technomark has sold many to big companies, he said, but the system is better suited for small workshops making different kinds of parts.

Boulkouane also noted that Graphix can handle marking applications ranging from low- to high-volume. When the system is integrated into a high-volume production line, he said, "it can work 24/7."