Gibbs and Associates announced that it began including a no-cost license of VoluMill Wireframe for GibbsCAM with each new license of GibbsCAM Production Milling. Until now, the ultrahigh-speed-toolpath engine was a fee-based option for GibbsCAM Production Milling, the primary milling package upon which a series of multi-axis GibbsCAM machining options integrate. Production Milling, which provides wireframe geometric modeling and toolpath generation for 2-, 2.5, and 3-axis machining, with 4th axis positioning, will now have VoluMill integrated within its traditional, shop-friendly interface. VoluMill Wireframe for GibbsCAM is a high speed machining process developed specifically to achieve the highest material removal rates while extending tool life through smooth transitions and constant tool loading. Customers have reported cycle time reductions as high as 70 percent and tool life extension of five times, according to the company.

"Although we believe that our software already carries exceptional value, we are pleased to offer this incremental value to customers," said Robb Weinstein, senior vice president of sales and strategic planning of Gibbs and Associates. "They will achieve the greatest productivity possible in roughing parts, and quickly see how VoluMill's ultrahigh-speed machining, with its optimal material removal rates, translates into high-speed part production at lower cost through savings in time, tools, and machine maintenance."

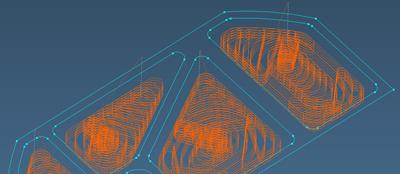

Traditional roughing toolpaths are typically generated as parallel offsets with sharp corners and transitions, requiring stops, starts and variable speeds to optimize motion and protect cutting tools from excessive wear and breakage. In contrast, VoluMill generates toolpaths optimized for volumetric material removal by using continuous tangential motion, specialized contour ramping, adaptive feed rates, and chip thickness control, achieving the highest feeds and speeds possible. By leveling tool load, maintaining constant machine-tool motion and using high-speed-repositioning, the software produces more efficient toolpaths, extends tool life and significantly reduces cycle times. No additional optimization is required.

VoluMill for GibbsCAM works on any combination of part and stock boundaries, and supports an unlimited number of islands, walls, pocket depths and island heights.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.