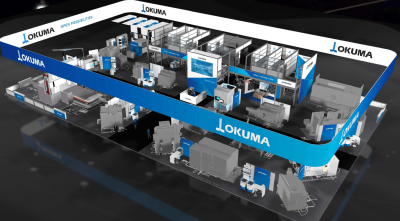

Okuma America Corporation, a world-leading manufacturer of CNC machine tools, announces the world debut of an interactive, virtual showroom experience.

Visitors can experience Okuma’s showroom at their convenience with a self-guided tour. A helpful navigational guide allows visitors to explore various areas of the showroom which include machines, technologies, service programs, podcasts, partner highlights, machine specials, and an overview of Okuma’s industry-leading distribution network. More specifically, visitors have the opportunity to view in-depth machine videos, interact with 360-degree machine renderings, and chat with Okuma experts during the tour.

“Covid-19 has changed the way the world interacts for the foreseeable future. Okuma has embraced these changes by creating a safe, virtual showroom for our customers. I’m proud of the work and the efforts of my team in creating a first-class, virtual experience for visitors to come and view at their convenience,” said Jim King, President and COO, Okuma America Corporation.

Virtual showroom highlights

- 17 Machines: lathes, multitasking machines, machining centers, grinder, and double column

- Technology: Artificial Intelligence (AI), automation, Connect Plan, Collision Avoidance System (CAS), Okuma’s App Store

- Service: spindle and electrical exchange, machine warranty, preventive maintenance, training

- Podcasts: Shop Matters episodes

- Distributors and Partners: learn more about our distributors and partners and how they can help solve manufacturing challenges

- Virtual Show Specials: 100 machines available for immediate delivery

Experience Okuma’s interactive, virtual showroom at www.okuma.com/showroom.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- multifunction machines ( multitasking machines)

multifunction machines ( multitasking machines)

Machines and machining/turning centers capable of performing a variety of tasks, including milling, drilling, grinding boring, turning and cutoff, usually in just one setup.