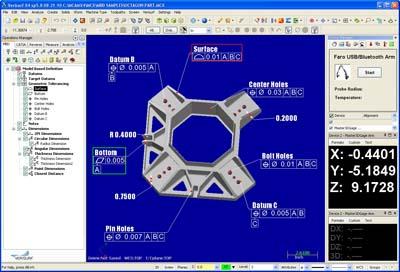

Verisurf Software Inc. released the 5th generation of its Verisurf X software. With Model-Based GD&T Inspection technology at its core, the all-new computer-aided inspection and reverse engineering software inspects parts faster and more accurately without any need for 2D drawings. Verisurf Model-Based GD&T data can be: Imported from or created on virtually any 3D CAD/CAM model Inspected to manually or as part of an automated inspection process Reported on in a variety of industry formats Verisurf's new 3D Feature Scan technology automates the collection of discreet inspection points on 3D CAD models. This gives users all of the flexibility of non-contact 3D scanning without the time-consuming processing and issues associated with massive point clouds. Verisurf's new Database Write feature formats and writes inspection information to SPC applications and PLM databases used by major global manufacturers. The feature also supports Microsoft Access and SQL Server database formats for integrating Verisurf inspection data with numerous enterprise databases. Verisurf's enhanced Auto Inspection Planning now performs automatic calculation of composite positional tolerances, eliminating hours of Excel spreadsheet calculations and plotting by quality assurance personnel. Auto Inspection Planning also has a new deviation display column that continuously views all measured deviations. Verisurf's updated Measure module has new assembly guidance arrows with resizable digital readout panel. Working in conjunction with Verisurf's industry leading Model-Based Inspection planning automation, the module helps users take more accurate measurements in the exact order and at the precise location needed.

Contact Details

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- statistical process control ( SPC)

statistical process control ( SPC)

Statistical techniques to measure and analyze the extent to which a process deviates from a set standard.