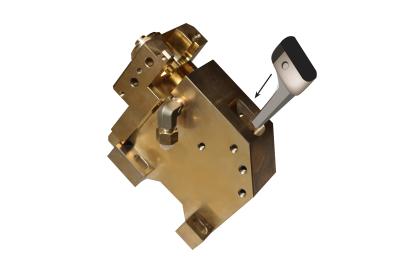

MC Machinery has introduced the Van-TG Lower Roller Nest Conversion Kit. With this kit, users can quickly upgrade their Mitsubishi EDM FA series machine(s) lower roller housing to the new Van-TG replaceable nest developed for Mitsubishi’s latest MV series EDMs. This kit enables users to reduce downtime, increase productivity and eliminate wire grooves from scraping.

Over time, the lower roller housing in an EDM may get grooves due to wear, which can cause issues with threading and general cutting. The new Van-TG Lower Roller Nest Conversion Kit allows users to replace the nest in the roller bearing housing within minutes. This eliminates hours of costly manual work and machine downtime.

Unlike replacing the roller housing, no additional alignment is required when replacing the Van-TG Lower Roller Nest. The removal nest can just be checked and replaced during regular recommended maintenance to make sure there is no wear present.

Contact Details

Related Glossary Terms

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.