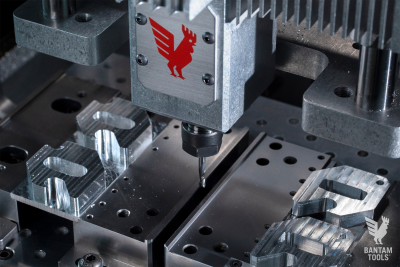

Bantam Tools, the desktop CNC manufacturer, is launching Bantam Tools Turnkey Solutions. This CNC service gives designers, engineers, and entrepreneurs a proven process to turn designs into physical parts. Bantam Tools engineers will develop a process for machining parts using the Bantam Tools Desktop CNC Milling Machine, then provide the know-how directly to customers, so they can then make those parts on their own. The goal is to empower Bantam Tools Desktop CNC Milling Machine users to mill with confidence.

“Our engineers build a bridge to help designers and engineers learn how to machine parts on our Bantam Tools Desktop CNC Milling Machine with confidence,” said Ron Lorentzen, general manager of Bantam Tools. “This helps parts survive the journey across the challenges and chasms of DFM, CAM, filtering, speeds and feeds and tooling.”

The Bantam Tools Turnkey Solutions is set up to help companies make parts faster using the Bantam Tools Desktop CNC Milling Machine. The service gives designers, engineers and companies a shortcut for figuring out a process to mill on a CNC machine. Depending on the parts a client needs, Bantam Tools will deliver items, such as:

- Work instructions for how to set up and run your job

- Fusion 360 file with vetted CAD model and CAM toolpaths

- .BTP file that saves the job setup in the Bantam Tools software

- G-code files that were exported from the Fusion 360 file

- Expertly engineered custom fixturing (either designs or fabricated)

- The finished part(s)

- A list of suggested machine tooling and accessories used to mill the part

“We’ve had customers get really excited about the Bantam Tools Turnkey Solutions,” said Ron Lorentzen. “There are a lot of companies out there who are needing to bring prototyping in-house and they need aluminum parts, but aren’t quite sure how to go about designing for and using a CNC milling machine. We can help remove those pain points and give customers the know-how to succeed.”

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- milling machine ( mill)2

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.