Kitagawa NorthTech Inc. provides turnkey, custom engineered workholding services. The company also provides design, engineering, workholding manufacturing, assembly, testing, inspection, documentation, installation and training.

Whether a machine shop is experiencing a productivity challenge or a specific machining problem hindering parts manufacturing in the production operation, Kitagawa NorthTech’s in-house Productivity Team provides advanced applications engineering assistance and custom engineered workholding systems manufacturing. Kitagawa NorthTech’s custom engineered workholding services are suitable for a range of machining applications for vertical, horizontal, and multiple-axis prismatic milling and turning, forging and casting applications.

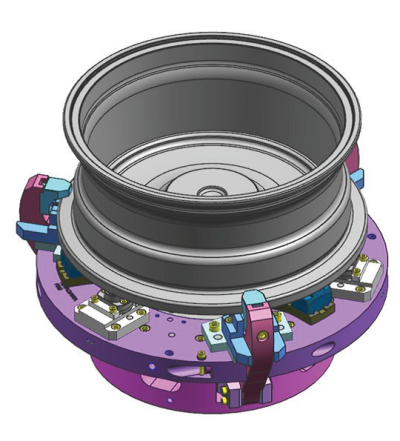

Kitagawa NorthTech’s dedicated productivity team engineers extensively study applications requirements, cutting conditions and workpiece drawings, which includes a review of geometric dimensional tolerance data. This is performed to identify the expectations and specific requirements of the customers’ application. The company utilizes state-of-the-art, 3D software modeling tools, formulas and customized equipment to help design and engineer custom workholding solutions quickly, efficiently at the lowest cost possible.

Kevin Bennett, vice president of sales and marketing, states, “From eliminating bottle necks in machining operations, to reducing cycle times, scrap problems and/or parts slippage in the chuck, Kitagawa NorthTech’s Productivity Team engineers have the expertise, skill set and knowledge-base to solve almost any prismatic and turning workholding problem. We deliver the best custom workholding solution available for customers.”

To achieve total customer satisfaction, Kitagawa NorthTech understands custom engineered workholding needs to work flawlessly and consistently on every production run. The company wants this to be a painless process for customers. Its comprehensive testing and inspection process will guarantee that outcome, according to the company. Once an engineered workholding design is manufactured, the Kitagawa NorthTech Productivity team conducts a series of inspection processes and rigorous tests to ensure the new engineered solution performs exactly as stated and specified. The process includes a battery of tests which includes inspection of every component of the system, dry fitting components for proper assembly, and run outs and repeatability values testing of the workholding system.

Throughout the entire testing and inspection process, the company documents all testing and inspection efforts and records the results as an added quality control measure to guarantee machining success. This facilitates the customer’s setup, installation and testing process. It provides important data and references points for the customer’s own in-house testing. The customer can also take comfort that Kitagawa keeps all documentation for future assistance. Finally, Kitagawa NorthTech also offers installation and training services if required by the customer.

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.