Gibbs and Associates, developer of GibbsCAM software for programming CNC machine tools, offers two new GibbsCAM options specialized for simplifying the machining of turbo machinery parts (rotary parts with blades).

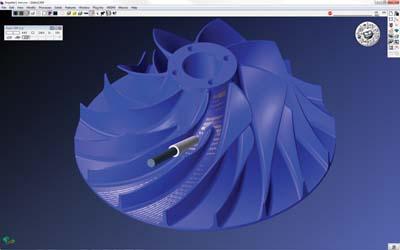

The two new GibbsCAM options, 5-Axis-MultiBlade and 5-Axis-Advanced MultiBlade, are fully integrated into GibbsCAM for use on machining centers and MTM machines. The options offer two levels of sophistication, both built with a specialized and dedicated interface within the GibbsCAM 5-Axis option. The MultiBlade interface provides access to toolpath strategies used in machining bladed parts, such as impellers, blisks (bladed disks) and blings (bladed rings), which are used in multiple industries where fluid (gas or liquid) compression or pressurized flow is required, chiefly aerospace, automotive and power generation. Consistent with the rest of the GibbsCAM NC programming environment, the new modules are easy to learn and easy to use.

"This exposition provides a global market for highlighting GibbsCAM 2011 and introducing our new MultiBlade Options," said Robb Weinstein, Senior Vice President of Sales and Strategic Planning of Gibbs and Associates. "The desire for efficiency is driving rapid growth of 5-axis machine tool use and the trend toward making turbo machinery parts is expanding beyond familiar components such as those within jet engines. Both trends provide a great opportunity for manufacturers to adopt our 5-Axis-MultiBlade Options."

While the GibbsCAM 5-Axis module is a powerful multi-purpose programming tool, very capable of generating toolpath for all parts requiring simultaneous 5-axis motion, the MultiBlade Options simplify machining of bladed parts, beginning with its integration within the GibbsCAM environment. Equally important is an intuitive, easy-to-use interface, which uses common turbo machinery terminology. Another simplification is that geometric manipulation is not necessary, because the MultiBlade Options work directly from the geometric model. Users need only select predetermined items such as the hub, blade, shroud. to begin programming. Furthermore, toolpath strategies available within MultiBlade are only those required or typically used to machine those geometric elements, but with all the flexibility to specify machining parameters.

The GibbsCAM 5-Axis-MultiBlade Option is designed for machining parts of simple to moderate complexity, and provides a subset of the features within the 5-Axis-Advanced MultiBlade Option, which adds functionality for machining highly complex parts. User requirements determine which module is best for the individual manufacturer. Both 5-Axis MultiBlade Options are supported within the GibbsCAM MTM (multi-task machining) module. There is automatic gouge checking on all toolpaths, and GibbsCAM Machine Simulation supports the MultiBlade Options, as do GibbsCAM 5-axis postprocessors.

General Features of 5-Axis Advanced MultiBlade include:

5-axis simultaneous roughing

5-axis simultaneous blade, splitter and hub finishing

Spiral blade finishing Leading- and trailing-edge control

Tool axis tilt controls Various edge-roll options

Tangential and radial toolpath extension

Automatic axis detection

Tool axis smoothing

Multiple splitter machining

Splitter smoothing

Various options for toolpath rotations and sorting

Stock definition for rest machining

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.