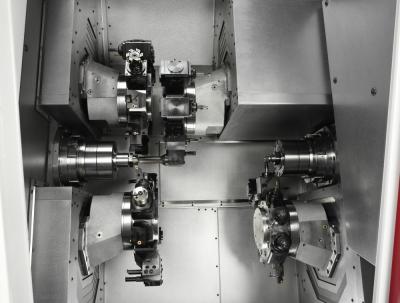

Designed to machine complex parts from bar diameters to 65 mm (2.559 inch) and a length of up to 300 mm (11.811 inch), the TNX65/42 delivers piece costs that are globally competitive. The basis for this productivity is two identical main and counter spindles and four turrets, each capable of holding 10 live or fixed quick change VDI tools. Each turret is capable of traveling in X, Z, and Y direction. A total of up to 80 tools can be accommodated using double tool holders, reducing setup times further, even for complex parts processes.

The unsurpassed simultaneous use of four tool carriers/four tools in cut plus main and counter spindles in combination with powerful live tool drives (7.4 hp, 6,000 rpm) permits extremely productive, diverse machining processes in a single setup.

The productivity of the four turrets is enhanced by the fact that each of them is capable of working on main and counter spindles. Therefore, four turrets could work simultaneously on one of the two spindles. Because the turrets are not dedicated to a spindle a maximum of overlap between the four turrets is possible. This guarantees the highest productivity and lowest per piece cost, according to the company.

Symmetrically designed, the turrets are arranged on independent slides above and below the spindle centerline. The main and counter spindles are driven by synchronous-type motor spindles and are identically rated at 24kW (32 hp) and 5,000 rpm for the 65 mm bar capacity machine and 28kW (37 hp) and 7,000 rpm for the 42 mm bar model. Hybrid bearings are fitted as standard for long service life.